Jetskigoodies

Well-Known Member

Last week we offered to install a motor for a member, we did not end up doing his but another member saw our post and asked us to do his.

This week [MENTION=58245]scrisp[/MENTION] dropped off his 96 xp with a couple boxes of parts and a rebuilt motor from 5starservices.

He had his motor out and a rebuilt one ready to go. He had his lines all plugged but one of the oil lines leaked and we had a mess on our hands.

There was alot more that was after a couple rinses and drainings.

It took us quite a while to get it all out. The oil that was in it gelled up on everything and was a pain to get off.

It cleaned up well though

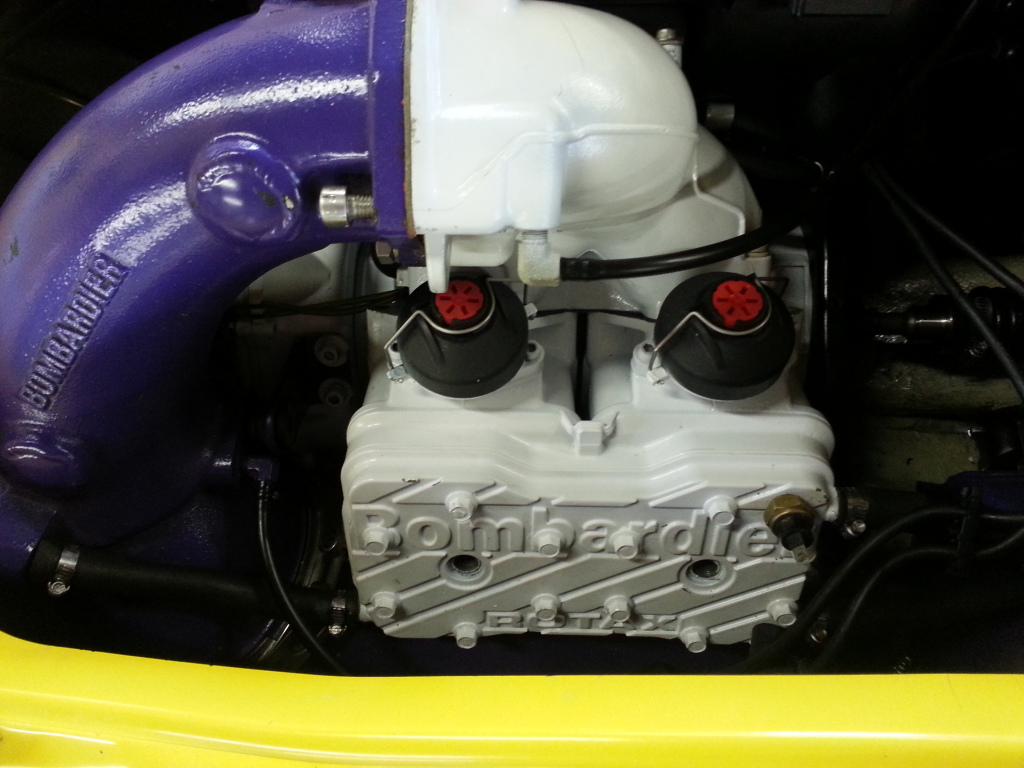

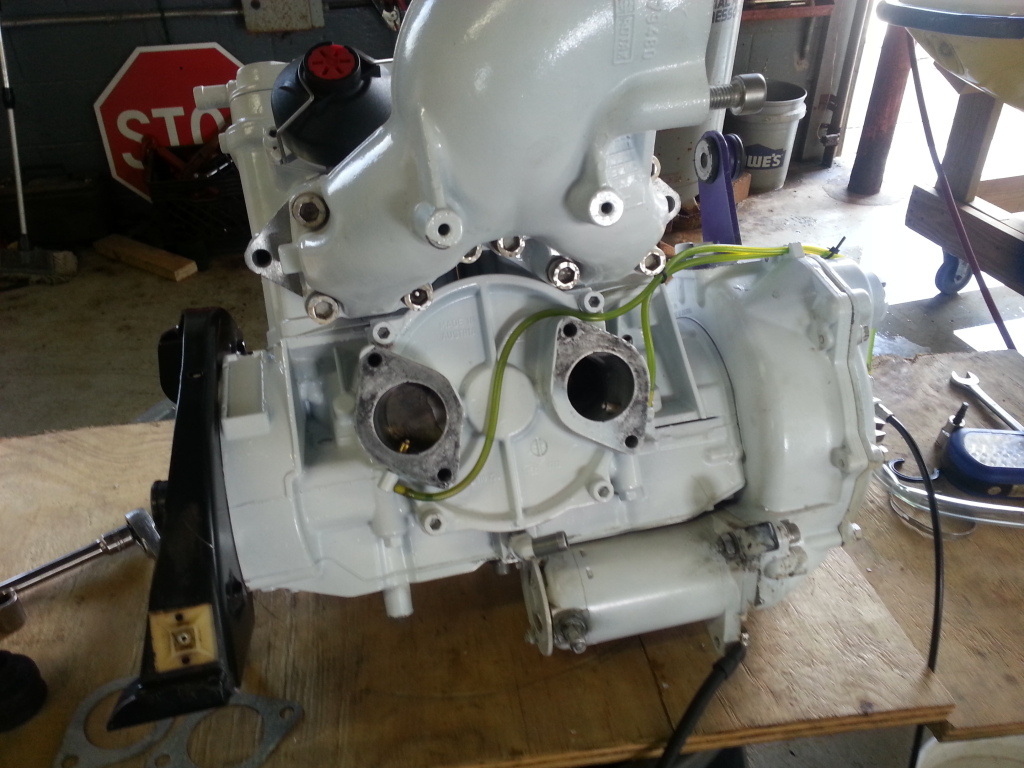

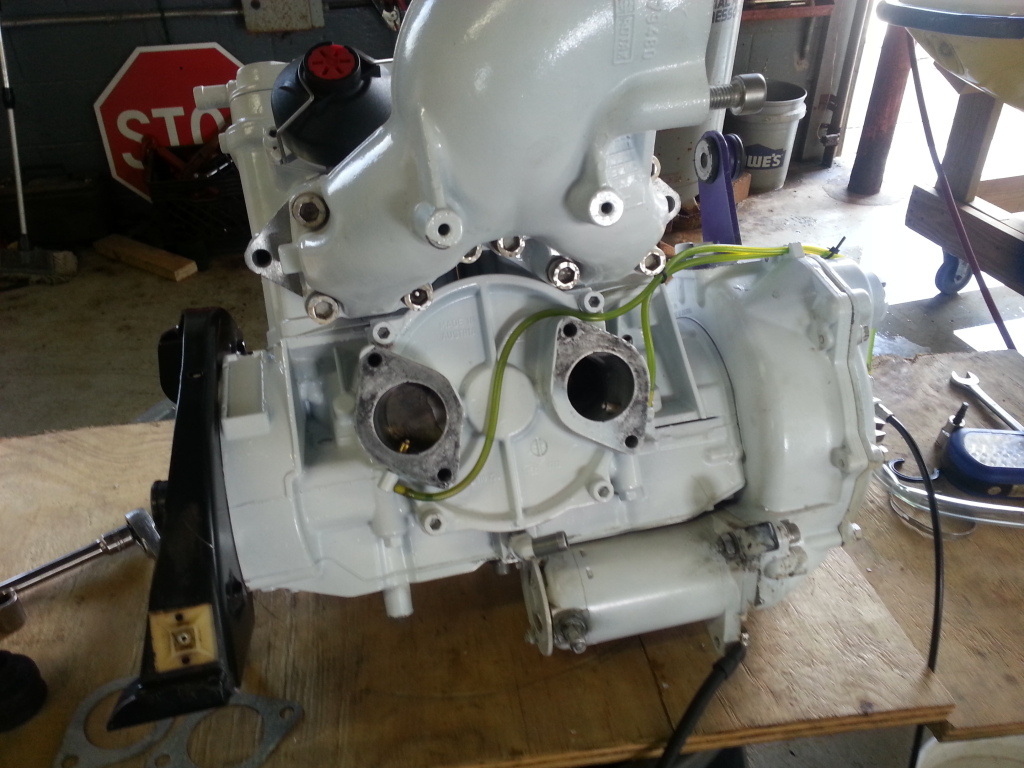

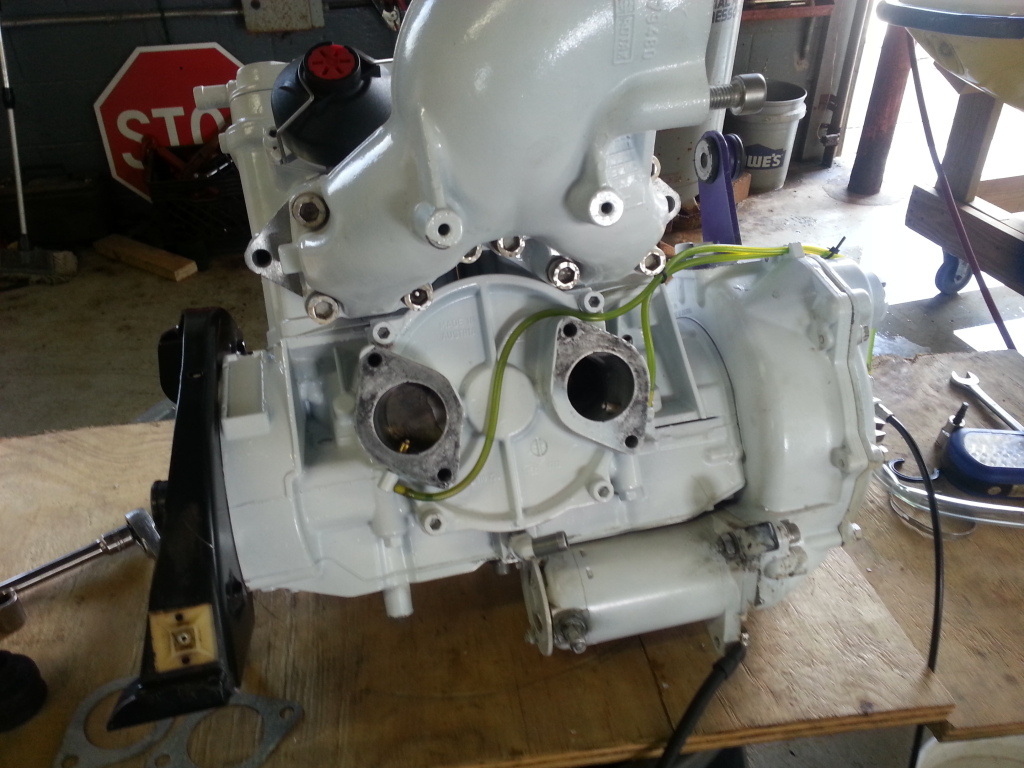

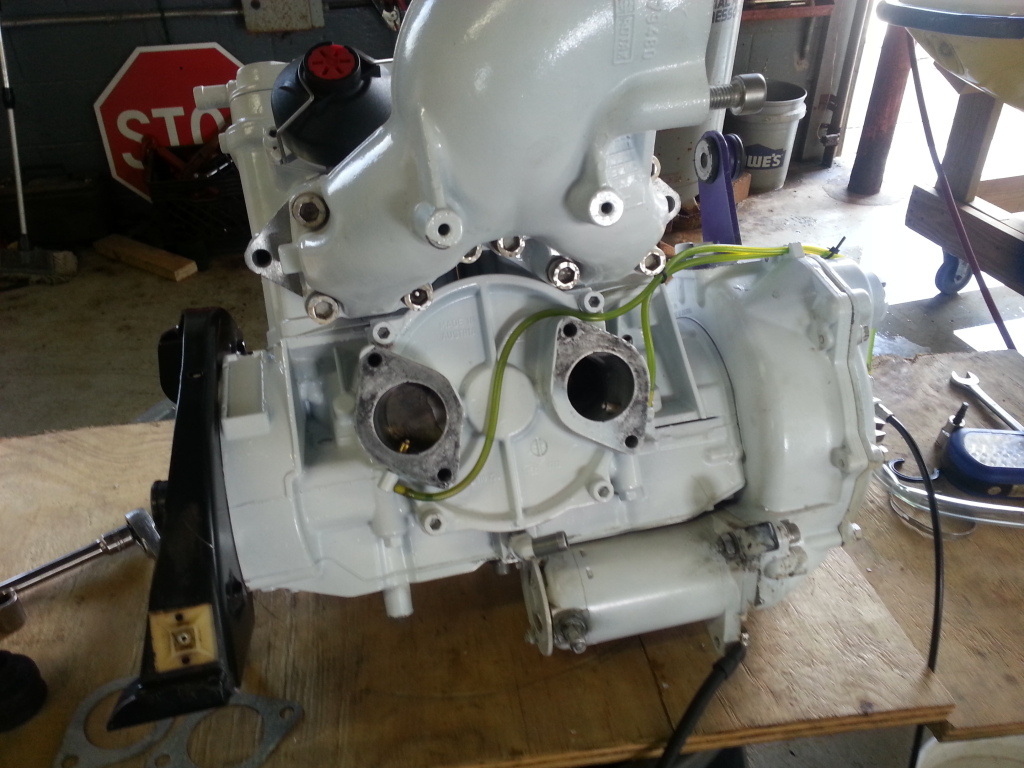

Here is the motor he got.

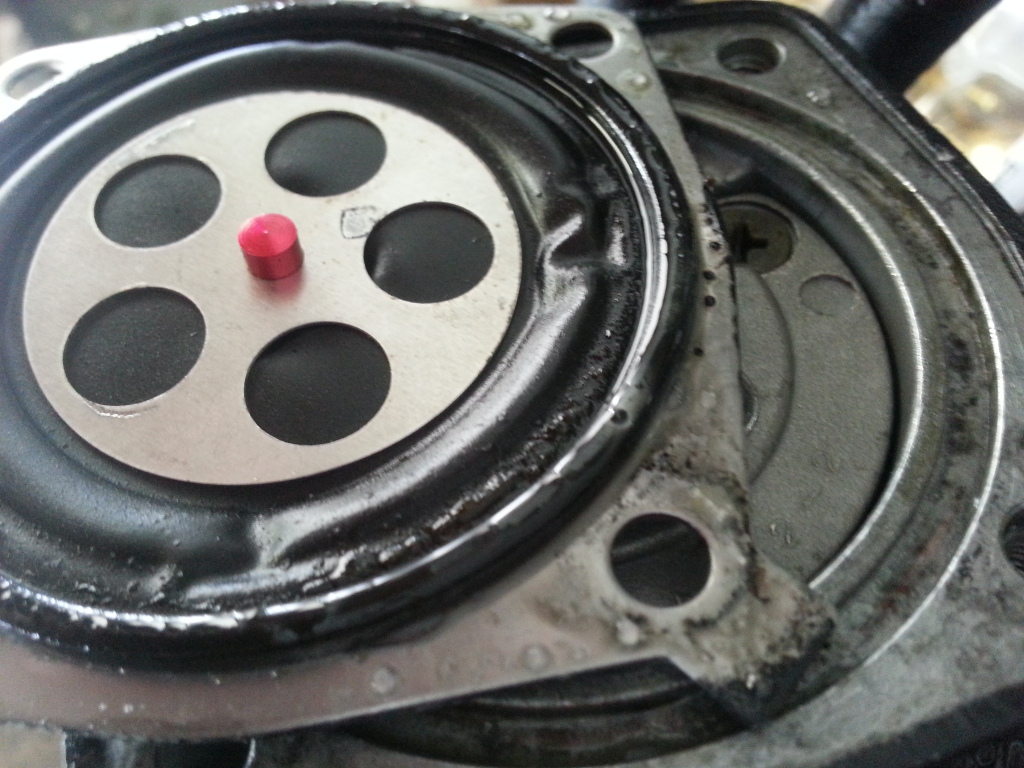

They had bit of overspray in certain areas. Like on the raves

I used a scotchbrite and got it off

We found a couple issues we took care of.

This was the main feed oil line, it was kinked and would not let the oil flow, it was very hard and was stuck in that shape.

So we replaced that.

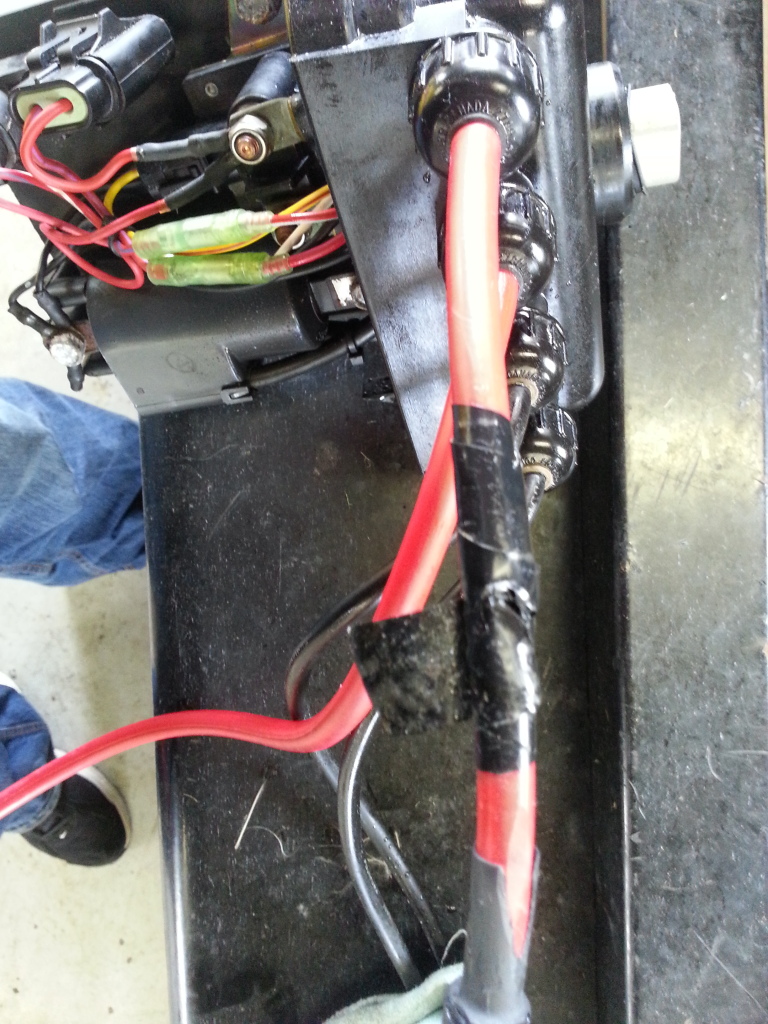

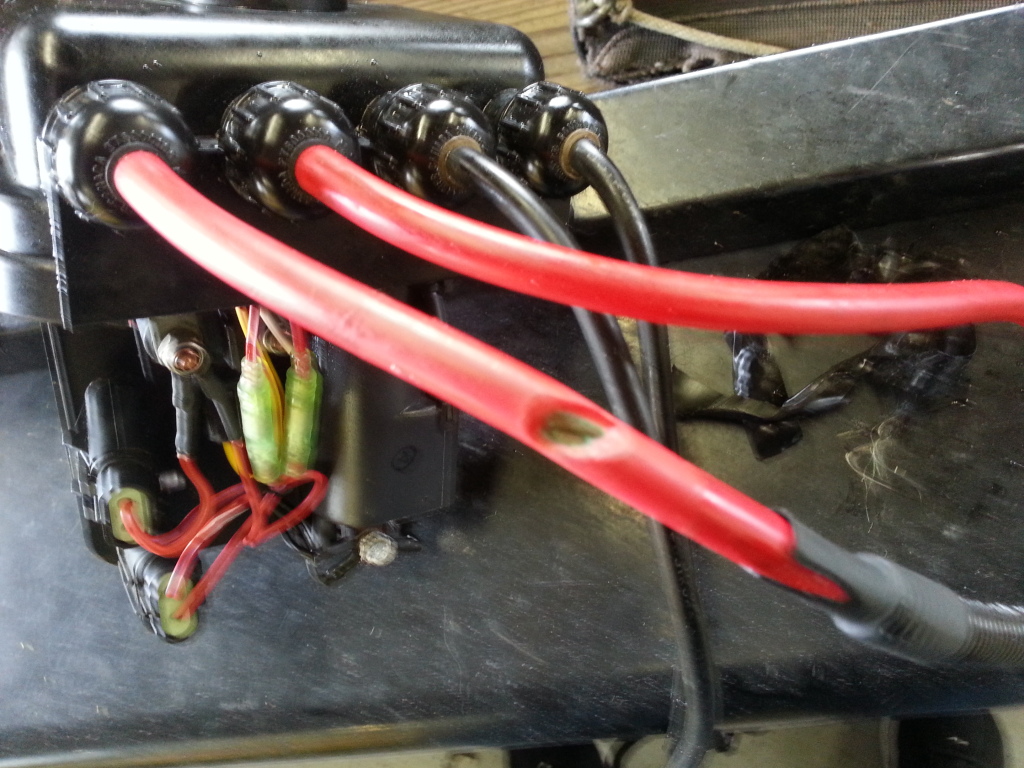

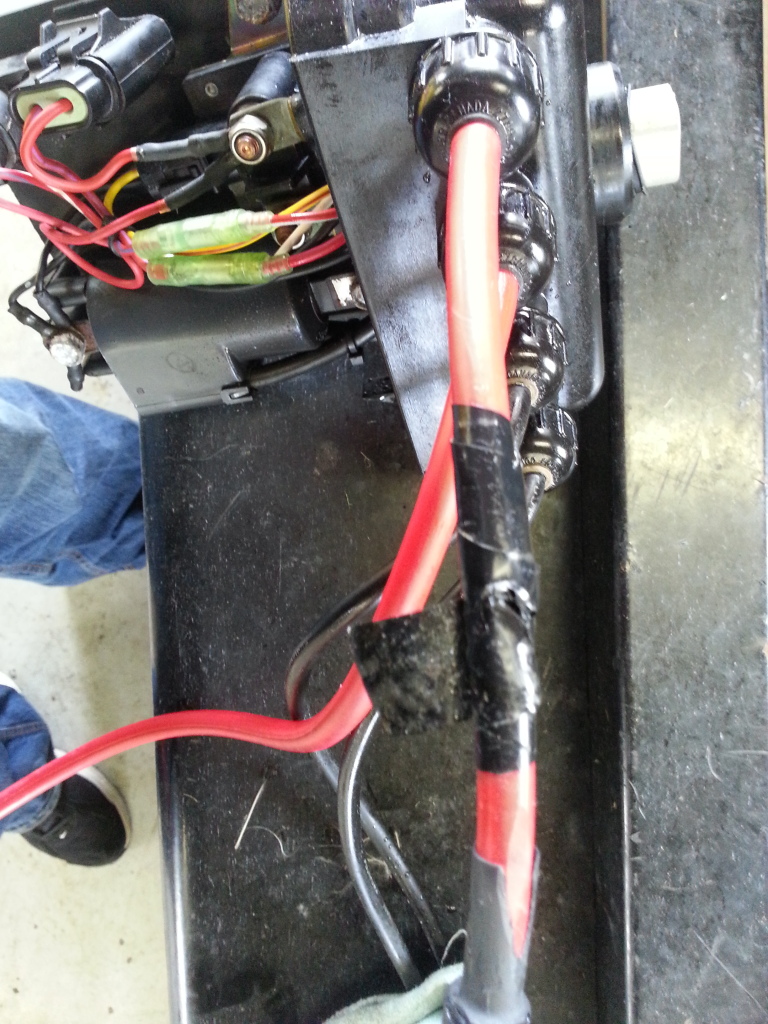

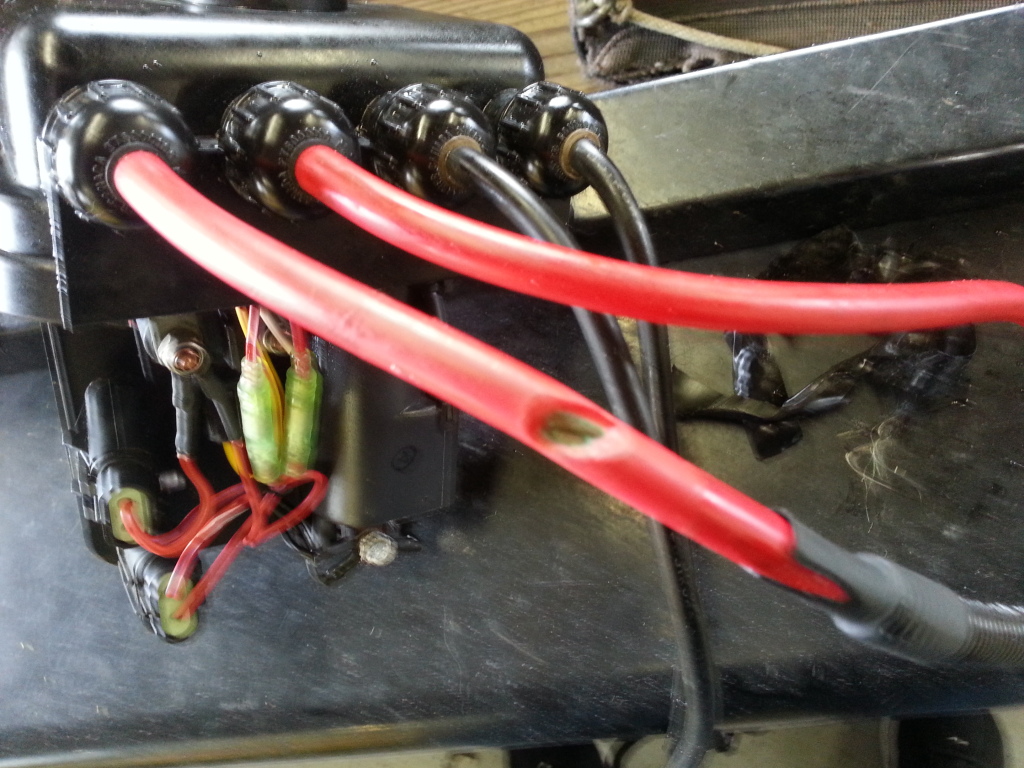

A positive wire coming from the rear ebox had a gash in it with electrical tape over it.

We replaced it with this.

The choke cable was rusted and when we took it out it actually snapped were the cable met the rod.

We replaced that.

This week [MENTION=58245]scrisp[/MENTION] dropped off his 96 xp with a couple boxes of parts and a rebuilt motor from 5starservices.

He had his motor out and a rebuilt one ready to go. He had his lines all plugged but one of the oil lines leaked and we had a mess on our hands.

There was alot more that was after a couple rinses and drainings.

It took us quite a while to get it all out. The oil that was in it gelled up on everything and was a pain to get off.

It cleaned up well though

Here is the motor he got.

They had bit of overspray in certain areas. Like on the raves

I used a scotchbrite and got it off

We found a couple issues we took care of.

This was the main feed oil line, it was kinked and would not let the oil flow, it was very hard and was stuck in that shape.

So we replaced that.

A positive wire coming from the rear ebox had a gash in it with electrical tape over it.

We replaced it with this.

The choke cable was rusted and when we took it out it actually snapped were the cable met the rod.

We replaced that.