Bonmotwang

Well-Known Member

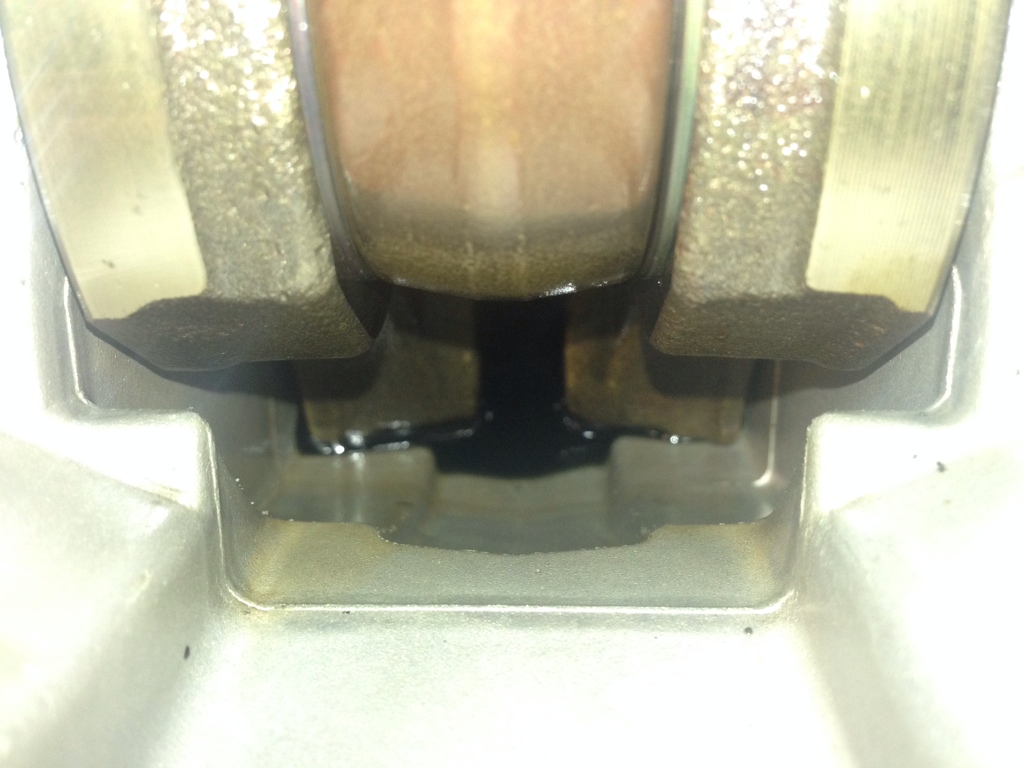

Oh about the crank case. Do I need to clean up suck put the oil puddle down there. One of my picture is showing an oil puddle there.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

No leave that oil puddle in there unless it was somehow contaminated! If it was, suck it out and replace it. When the engine starts the first time that oil gets slung up through the windows in the rods and all over everything else that matters.

There's very little oil coming in from the pump at normal throttle settings for in water idle speed. I actually think it might be a far better idea to start that motor in the water to avoid the initial 3K rpm out of the water routine with the impeller having no resistance to slow it down.

this running and in the water yet?

We call than an ounce, put just a little more back in there (like 50%) more that won't hurt anything when it starts the crank in motion. You want to roll the engine over briefly without the plugs in to let everything oil up before it fires.

You couldv'e left the cylinders so he can test/confirm the RAVE fit if you're not assembling it yet.

You can use gasket stripper to clean those surfaces, or if you're careful insert a scotchbrite pad into your air powered die grinder (my preference), these are available ready to use at Home Depot I think.

I guess I need verify the fit at home now. It is already done. I will pick them up with XPS II oil in the afternoon.

How to check if the raves are fit?

Sent from my iPhone using Tapatalk

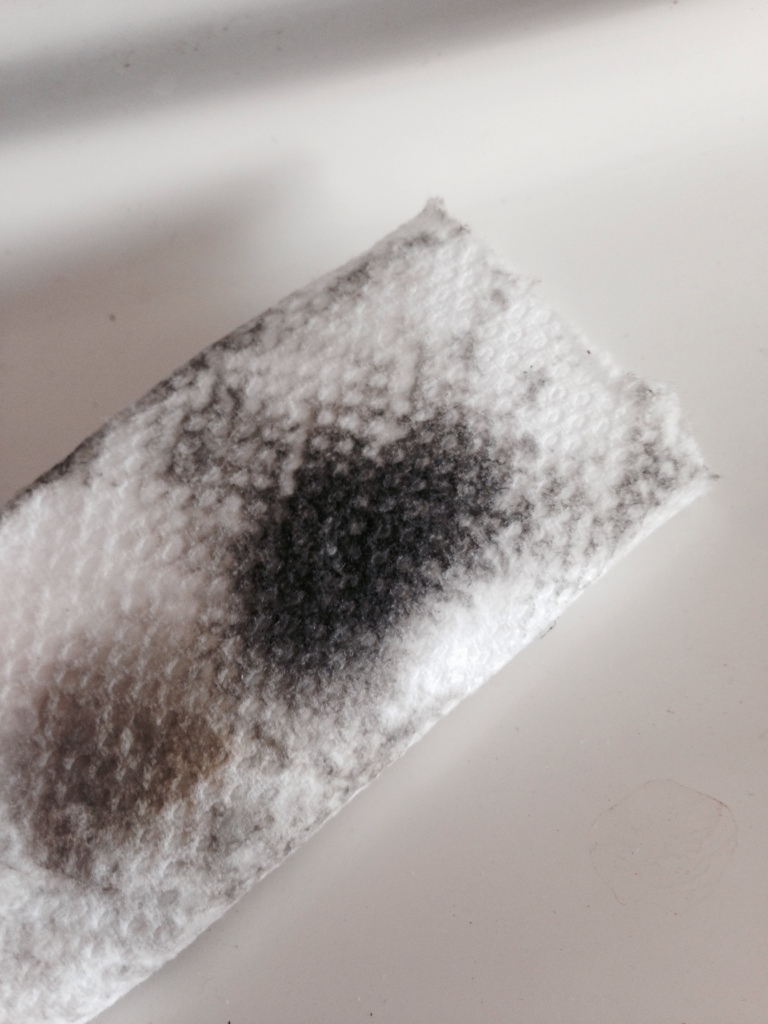

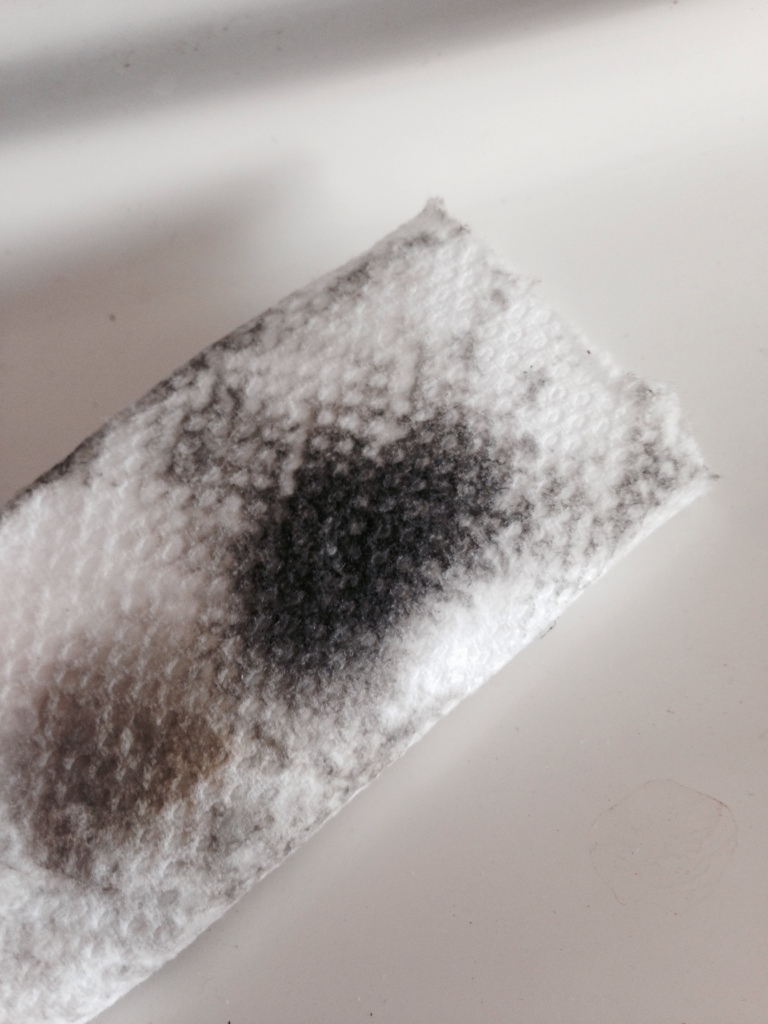

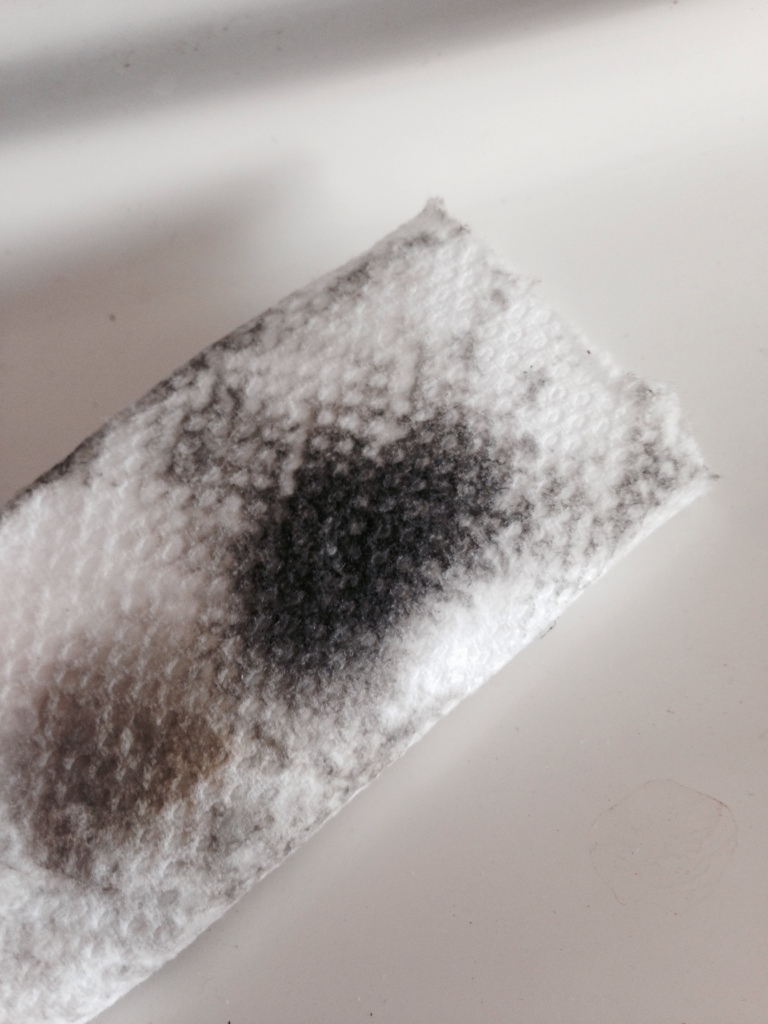

Ask him if he washed the cylinders and scrubbed them with very hot water, this is the only way to remove the remaining honing abrasive and MUST be done before assembly! After cleaning, a white paper towel wiped inside with wd-40 should be clean, not dirty looking. Unless maybe his hone was white, which hopefully wasn't.

I will use XPS II to lubricate all the parts when I install. Is it ok oil got into the bottom and top gaskets?

Sent from my iPhone using Tapatalk

This is what I got using wd40 wiping

Sent from my iPhone using Tapatalk

This is what I got using wd40 wiping

Sent from my iPhone using Tapatalk

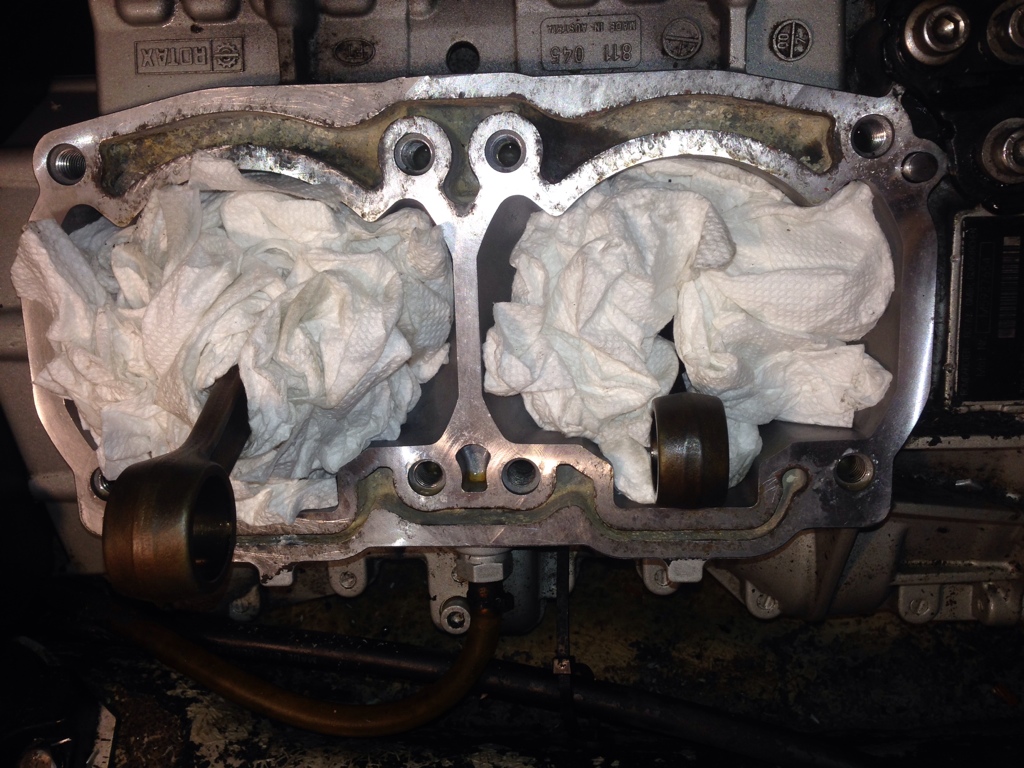

Is this deep corrosion pitting that might allow water to leak into crankcase?

No need to ask, LOL. He should tell you about this so you can clean them.