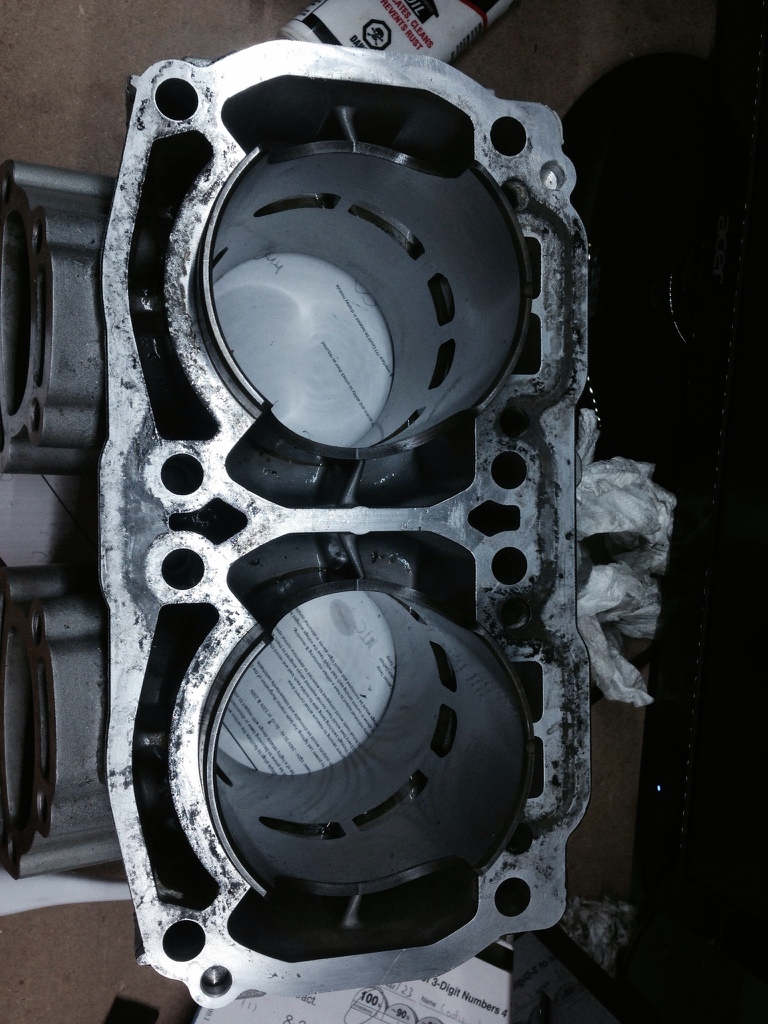

Is this the corrosion you are talking about?

But water passes through these holes, don't they?

Those 8 bolt holes are clean.

Still trying to find a solution to wash the cylinder with hot water. Something new :-D

Can I just sink it into a big pail and pour in boiling water and use a tooth brush to clean inside also outside and gasket surface?

It looks like rebuilding is all about details. If youtube does the teaching, then everybody can rebuild. I would consider you tube as the start

and gold is in here ... ...

Sent from my iPhone using Tapatalk

I thought I could see in the case under the base gasket of PTO cylinder there was aluminum corroded away but could be I mistook the photo. I placed a red oval in your photo where it looked that way and reposted it.

If all the surfaces look good there should be no problem IMO. The head gasket has a special coating on it to allow for expansion and contraction while sealing to the metal so I hope there isn't some oil to interefere. I really don't like to use any sealer if the surfaces are smooth and flat, the special coating on the head gasket is designed to work as it is but of course it cannot compensate for gouges, scratches or deep corrosion.

I think for the cylinder I would put it in the large sink and wash it with as hot of water as possible. Compressed air, dry towels and WD-40 can help avoid rusting but the abrasive must be washed away IMO. You can see abrasive with a white paper towel as before.

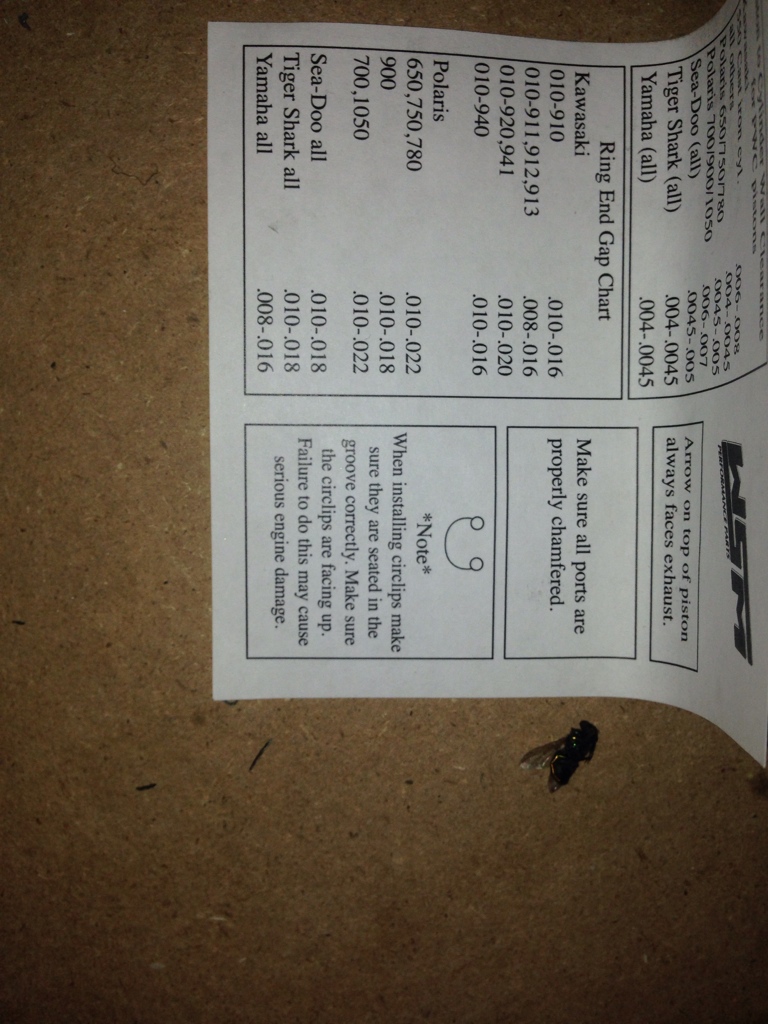

Hastings says this, about that:

"CYLINDER CLEANING

The single most critical factor of any cylinder refinishing job is the cleaning of that cylinder after the honing operation.

It can be stated, pistons, rings, and cylinder bores will forgive slight variations in roughness, cross hatch angle, etc. No engine component will tolerate dirt!

Honing cylinders leaves two types of "dirt" on the cylinder wall, honing stone residue, and cast iron dust. If not removed before the engine is reassembled, the world’s finest lapping compound is waiting to destroy all the hard work of assembly the instant the engine is started.

Proper cylinder cleaning consists of a thorough scrubbing of the block with hot, soapy water taking care to clean the surface under the cylinder facing the crankcase. Rinse with hot water, dry, and lightly oil to prevent rust.

For detailed honing questions it is wise to contact the manufacturer of your specific equipment. They are experts in metal finishing and of course completely understand their own equipment.

In general if the foregoing practices are used excellent engine performance will result. "

https://www.hastingsmfg.com/ServiceTips/cylinder_bore_refinishing.htm