Waterluvr

New Member

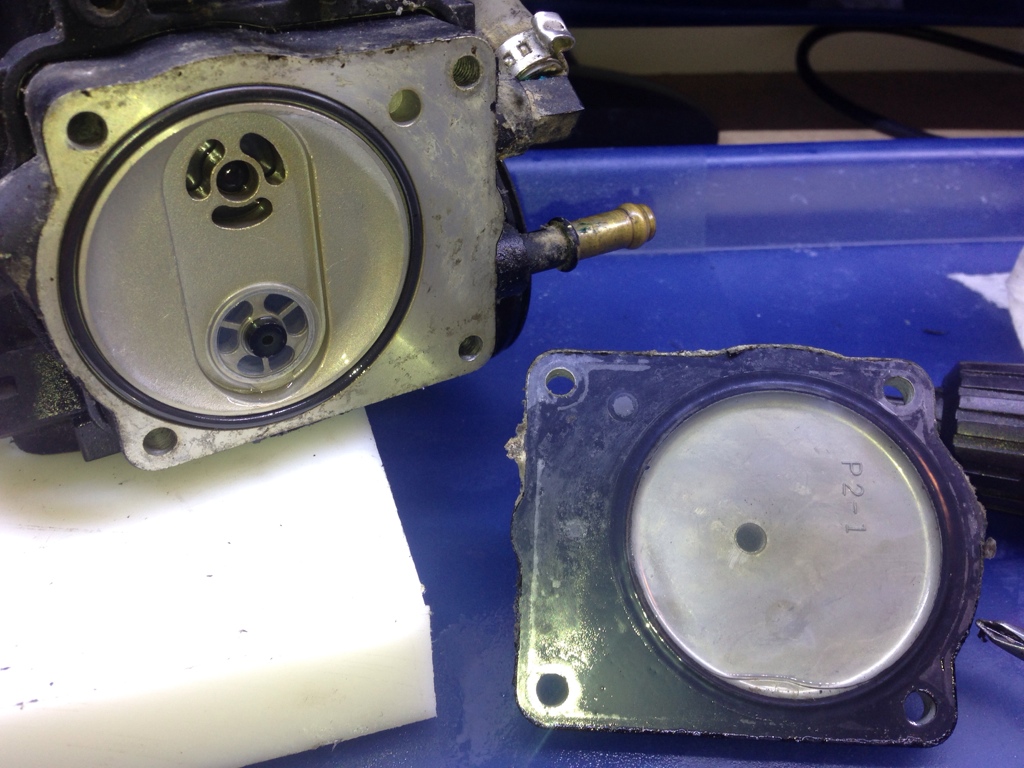

No leave the throttle/choke shafts and linkages in place. Now, every opening in that carb has a point or origin and point of exit through the passages where you want the cleaner to flow through.

Wear safety goggles so you don't get it in your eye's but you need to visually see it's flowing out when you insert the straw into an opening and flush it out.

Wear safety goggles so you don't get it in your eye's but you need to visually see it's flowing out when you insert the straw into an opening and flush it out.