Sportster-2001-951C-Stock

Well-Known Member

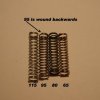

Does this look normal?

Sent from my iPhone using Tapatalk

Looks like aluminum barnacles, some amount of this will happen due to moisture penetration and acids maybe in the rubber but if the damage is minor and this doesn't leak then it's okay. Coat that surface with some oil to maybe slow the growth of barnacles.

Just wondering if there's some amount of oil in the crankcase, there should be a puddle there. Check for me next time you look unless you vacuumed it out already.