-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2001 Seadoo Sportster LE. Just got it!

- Thread starter Bonmotwang

- Start date

- Status

- Not open for further replies.

Waterluvr

New Member

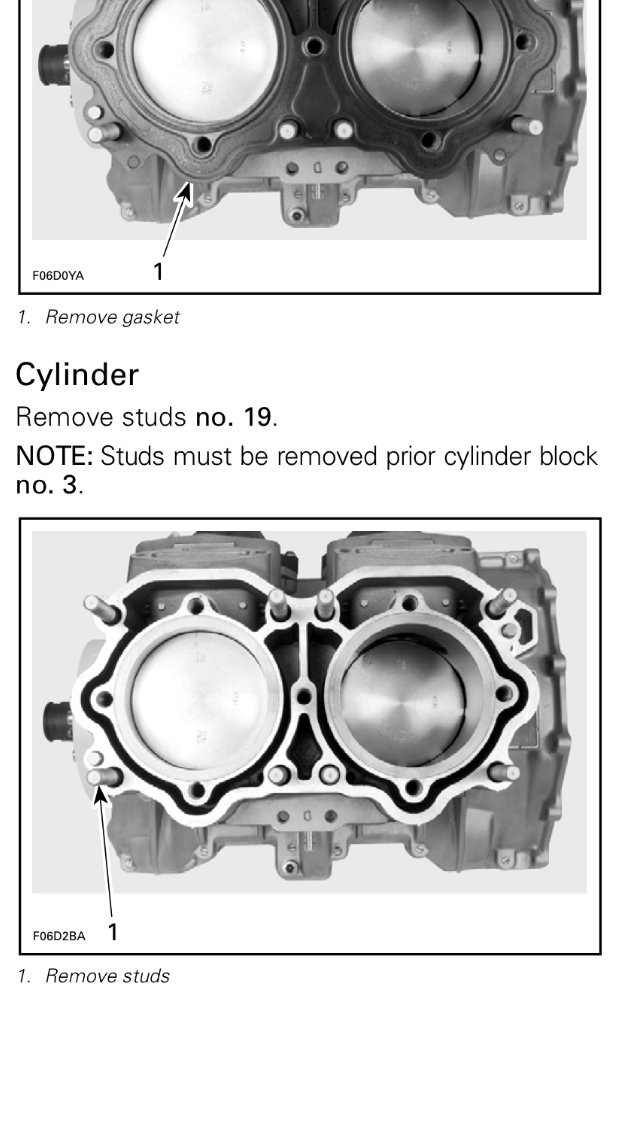

Yes Sir, just use two of the nuts from the head and screw them down to lock together and you can use those to back the studs out.Manual said you have to remove the rods/studs before remove the cylinder.

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

Stick an led light into the rave ports and then take each piston to top dead center. See any light around the piston rings/edges? It looks to me like you have had quite a bit of heat blowing by on those rings at this point.

Used the iphone flash at the port. I thought iphone fits the rave port well, but too big :-D

I think this test doesn't count. But anyway no light leak that way.

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

Yes Sir, just use two of the nuts from the head and screw them down to lock together and you can use those to back the studs out.

It is pretty tight. Is it normal way thread? I locked the two nuts by two wrenches, but they still moves together.

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

Too funny. Just realized that I need to take the whole exhaust out.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Waterluvr

New Member

Yes, the manual mentions this before you commence engine disassembly of the top end.:cheers: It's not coming up and off of there otherwise.Too funny. Just realized that I need to take the whole exhaust out.

Sent from my iPhone using Tapatalk

You'll be glad you did this, so far it looks like you caught it just in time. The idea with a top end job is to buy some time and restored performance at a much reduced cost versus a complete rebuild and it's not even an option once something let's loose. Those cylinder pics are enough to show wear to the degree that what you're doing right now is in no way premature at all.

Bonmotwang

Well-Known Member

Is that some pitting in the cylinder walls? If yes, I blame this on corrosion.

Is there a ridge you can feel at the top where the rings reverse direction? If yes, this represents cylinder wear near the top.

No pitting lines at the walls so looks like no corrosion has happened or minor but got cleared by the rings.

There is a ridge near the top edge.

Sent from my iPhone using Tapatalk

Sportster-2001-951C-Stock

Well-Known Member

Actually I'm a little surprised at the amount of cylinder wear, I didn't expect this much. Now I feel a need to inspect my piston skirts through the RAVE ports again, last fall they still looked good but it blew 120psi then.

First time I checked my motor the day I bought it, it blew 135psi but I'm not sure how much oil may have been in the cylinders.

First time I checked my motor the day I bought it, it blew 135psi but I'm not sure how much oil may have been in the cylinders.

Bonmotwang

Well-Known Member

Yes, the manual mentions this before you commence engine disassembly of the top end.:cheers: It's not coming up and off of there otherwise.

You'll be glad you did this, so far it looks like you caught it just in time. The idea with a top end job is to buy some time and restored performance at a much reduced cost versus a complete rebuild and it's not even an option once something let's loose. Those cylinder pics are enough to show wear to the degree that what you're doing right now is in no way premature at all.

Nice. Just laughing at myself. Thinking it just slides right out LOL.

Should call it a day. Remove the exhaust with a clear mind (don't know how much time it takes). Thanks guys.

Sent from my iPhone using Tapatalk

Waterluvr

New Member

Actually I'm a little surprised at the amount of cylinder wear, I didn't expect this much. Now I feel a need to inspect my piston skirts through the RAVE ports again, last fall they still looked good but it blew 120psi then.

First time I checked my motor the day I bought it, it blew 135psi but I'm not sure how much oil may have been in the cylinders.

Ya know I'm really glad he's getting into this right now and not putting another minute on that motor, all that heat blowing by at TDC is heading right down into the case and crank and you know the rest of the story.

Bonmotwang

Well-Known Member

Ok friends. I wish we drink together.

Couldn't believe I yank the engine apart.

Do i need a lift to take the exhaust out. Or hair remove half of the pipe?

Looks like to rebuild the carb too if the big black pipe is out?

Sent from my iPhone using Tapatalk

Couldn't believe I yank the engine apart.

Do i need a lift to take the exhaust out. Or hair remove half of the pipe?

Looks like to rebuild the carb too if the big black pipe is out?

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

So if we can confirm the low end is good enough, I will ship the top end to fullbore on Monday. I may just drive to US and ship it to avoid custom delays.

Is it the plan? If no surprises?

Sent from my iPhone using Tapatalk

Is it the plan? If no surprises?

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

Thanks. And appreciate all the help. I bought the carb rebuild kit last fall but didn't do it. Is the a way to add count balance oil from the top. :-D manual say 40ml. But with engine tilt in the bilge I was only able to put 15ml in before the last trip.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Waterluvr

New Member

So if we can confirm the low end is good enough, I will ship the top end to fullbore on Monday. I may just drive to US and ship it to avoid custom delays.

Is it the plan? If no surprises?

Sent from my iPhone using Tapatalk

Yes, what we didn't see was deep scarring from a broken ring on the cylinder walls and that's a good thing! I set notifications up to come to my phone so when you get back to working on it tomorrow post and I'll get back with you.

I'm anxious to see what those pistons look like tomorrow.

Bonmotwang

Well-Known Member

Yes, what we didn't see was deep scarring from a broken ring on the cylinder walls and that's a good thing! I set notifications up to come to my phone so when you get back to working on it tomorrow post and I'll get back with you.

I'm anxious to see what those pistons look like tomorrow.

Cool. I took a closer and awkward look though the raves again. It looks like the score lines are near the center of the rave ports. The mag side is much better.

I guess tomorrow we will nail down what is the cause and avoid it with the new top end?

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

Do I need to spay some WD40 into those long stubs holes? It seems very tight.

Is it ok to have wd40 into the cylinder and water jackets ?

Sent from my iPhone using Tapatalk

Is it ok to have wd40 into the cylinder and water jackets ?

Sent from my iPhone using Tapatalk

Sportster-2001-951C-Stock

Well-Known Member

The amount of wear on the aluminum + silicon alloy piston will be greater than the amount of wear to the cylinder bore, once this wear increases to the point the clearance is increased beyond maximum tolerance the rings are probably quite worn and have lost their tension against the cylinder as well thus the sealing is compromised.

Pitting and scoring of the cylinder walls also contributes to combustion gasses blow-by, causing overheating of the rings and piston, and oil film failure due to heat (oil cokeing/varnish). Excessive piston clearance will allow to piston to turn sideways in the bore (unparallel) and the bottom skirt bangs against the cylinder (piston slap), this action can crack/break the skirt just above the bottom, depending on the profile of the skirt.

There is a good amount of carbon on the piston crown, indicative of overheating in low hour motors. If you decide to remove the pistons then it will be interesting to see the underside of the piston crown to see if there is carbon there also. If you find carbon on the underside of the piston crown, this confirms the pistons were overheating (most likely due to compression loss and excess tolerance).

Also I noticed the squish band of the cylinder head seems to be pitted (a sandblasted look), it seems like this may have occurred due to detonation, (the squish band is the most likely location where detonation occurs).

What I didn't see though, was pitting of the piston crown around the same location as the squish band, so I'm unsure if detonation was actually occurring or if the sandblasted look of the cylinder head squish band is a "factory feature".

Pitting and scoring of the cylinder walls also contributes to combustion gasses blow-by, causing overheating of the rings and piston, and oil film failure due to heat (oil cokeing/varnish). Excessive piston clearance will allow to piston to turn sideways in the bore (unparallel) and the bottom skirt bangs against the cylinder (piston slap), this action can crack/break the skirt just above the bottom, depending on the profile of the skirt.

There is a good amount of carbon on the piston crown, indicative of overheating in low hour motors. If you decide to remove the pistons then it will be interesting to see the underside of the piston crown to see if there is carbon there also. If you find carbon on the underside of the piston crown, this confirms the pistons were overheating (most likely due to compression loss and excess tolerance).

Also I noticed the squish band of the cylinder head seems to be pitted (a sandblasted look), it seems like this may have occurred due to detonation, (the squish band is the most likely location where detonation occurs).

What I didn't see though, was pitting of the piston crown around the same location as the squish band, so I'm unsure if detonation was actually occurring or if the sandblasted look of the cylinder head squish band is a "factory feature".

Waterluvr

New Member

This is a normal occurrence when piston ring and cylinder tolerances increase over time and normal usage, the result is additional heat transfer past the rings and down the piston skirts thus melting and transferring aluminum and creating the visible scoring you see and measurable loss of compression.

In addition, the heat from combustion not being contained on top of the piston and rings is being transferred to the lower end of the case and crankshaft and bearings instead of out the exhaust port.

Now you understand why I wanted you to start repairs now and not wait?

In addition, the heat from combustion not being contained on top of the piston and rings is being transferred to the lower end of the case and crankshaft and bearings instead of out the exhaust port.

Now you understand why I wanted you to start repairs now and not wait?

Sportster-2001-951C-Stock

Well-Known Member

Do I need to spay some WD40 into those long stubs holes? It seems very tight.

Is it ok to have wd40 into the cylinder and water jackets ?

Sent from my iPhone using Tapatalk

Yes, you can spray WD-40, there will be no damage.

I suspect the studs were installed using lock-tite red so it may be necessary to heat them using a torch to soften the lock-itte.

I think you should be able to lift the cylinder assembly while the head studs are still installed, I don't understand why seadoo says you cannot..

Waterluvr

New Member

Do I need to spay some WD40 into those long stubs holes? It seems very tight.

Is it ok to have wd40 into the cylinder and water jackets ?

Sent from my iPhone using Tapatalk

Go for it, that won't hurt anything and might help soaking those studs overnight.

Bonmotwang

Well-Known Member

The amount of wear on the aluminum + silicon alloy piston will be greater than the amount of wear to the cylinder bore, once this wear increases to the point the clearance is increased beyond maximum tolerance the rings are probably quite worn and have lost their tension against the cylinder as well thus the sealing is compromised.

Pitting and scoring of the cylinder walls also contributes to combustion gasses blow-by, causing overheating of the rings and piston, and oil film failure due to heat (oil cokeing/varnish). Excessive piston clearance will allow to piston to turn sideways in the bore (unparallel) and the bottom skirt bangs against the cylinder (piston slap), this action can crack/break the skirt just above the bottom, depending on the profile of the skirt.

There is a good amount of carbon on the piston crown, indicative of overheating in low hour motors. If you decide to remove the pistons then it will be interesting to see the underside of the piston crown to see if there is carbon there also. If you find carbon on the underside of the piston crown, this confirms the pistons were overheating (most likely due to compression loss and excess tolerance).

Also I noticed the squish band of the cylinder head seems to be pitted (a sandblasted look), it seems like this may have occurred due to detonation, (the squish band is the most likely location where detonation occurs).

What I didn't see though, was pitting of the piston crown around the same location as the squish band, so I'm unsure if detonation was actually occurring or if the sandblasted look of the cylinder head squish band is a "factory feature".

Is the pointed area the squish band?

Waterluvr

New Member

Is the pointed area the squish band?

View attachment 26778

Yes, and normally with detonation issues the top of the piston and the squish area are both affected. Your's pistons don't show much for signs of detonation at all.

Here's an affected piston picture.

Sportster-2001-951C-Stock

Well-Known Member

Agreed, this engine seems to be at the limit of it's normal service life. If kept running in this condition, mechanical failure will occur.

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 334

- Replies

- 7

- Views

- 399

- Replies

- 7

- Views

- 852