-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2001 Seadoo Sportster LE. Just got it!

- Thread starter Bonmotwang

- Start date

- Status

- Not open for further replies.

Bonmotwang

Well-Known Member

No, keep going those pistons aren't gonna unscore themselves.

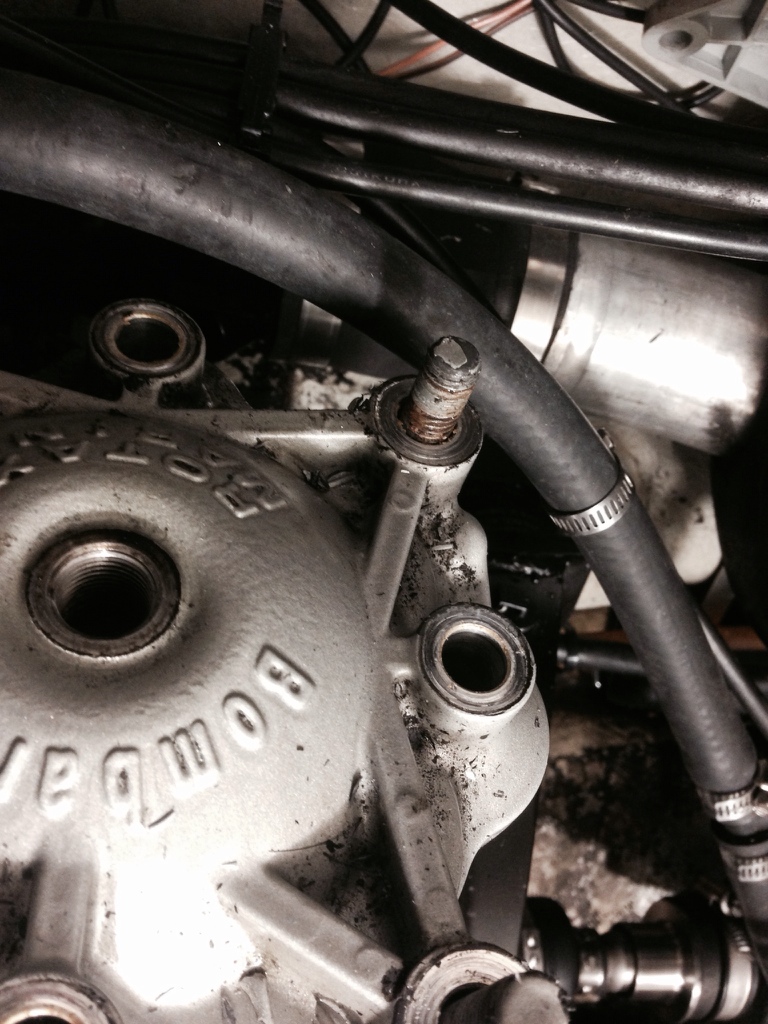

Ok. The middle screw came out like this with grease on the top

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

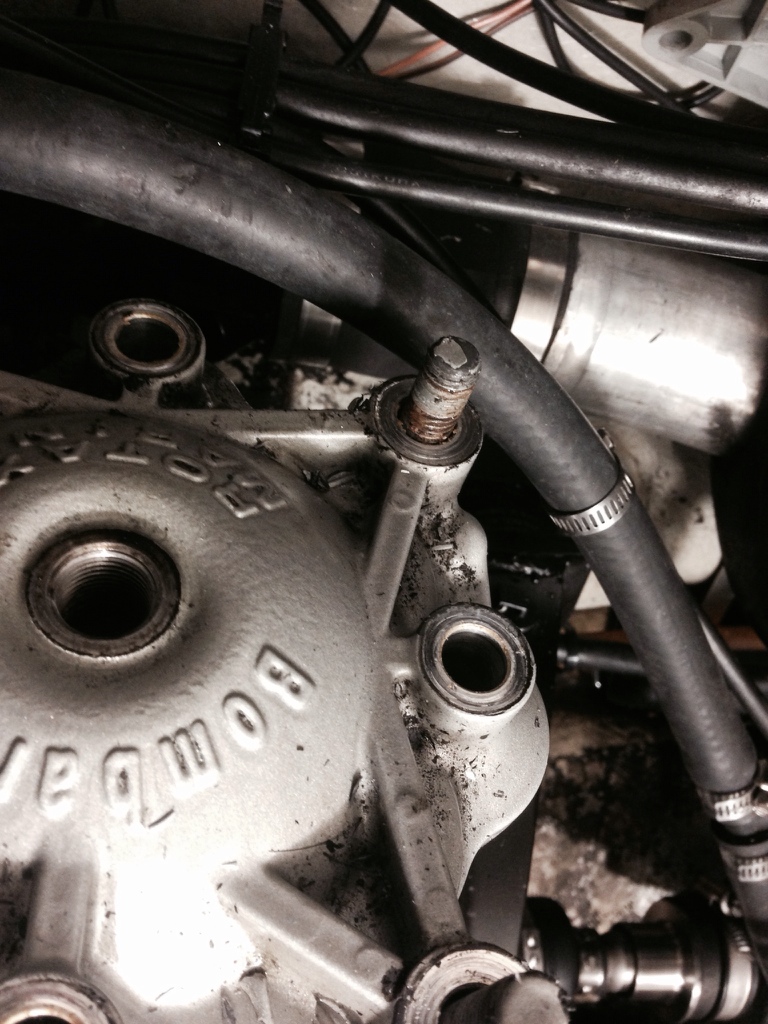

All screws out.

Only one rod has a sign of rust

Sent from my iPhone using Tapatalk

Only one rod has a sign of rust

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

How to get the head loose?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

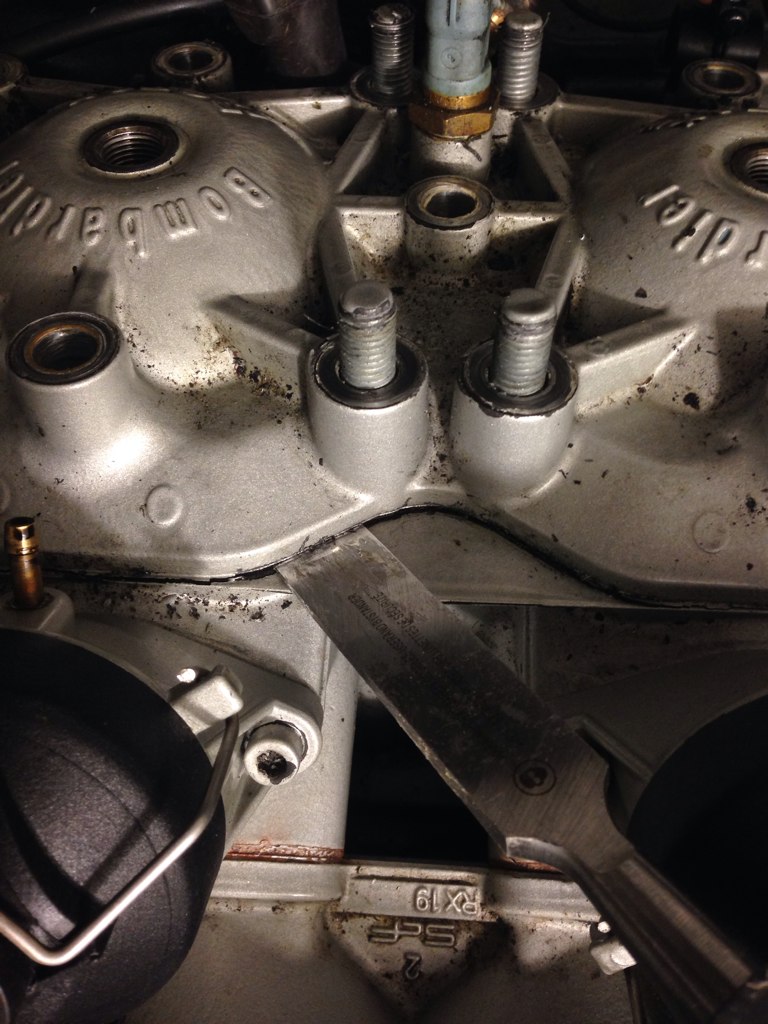

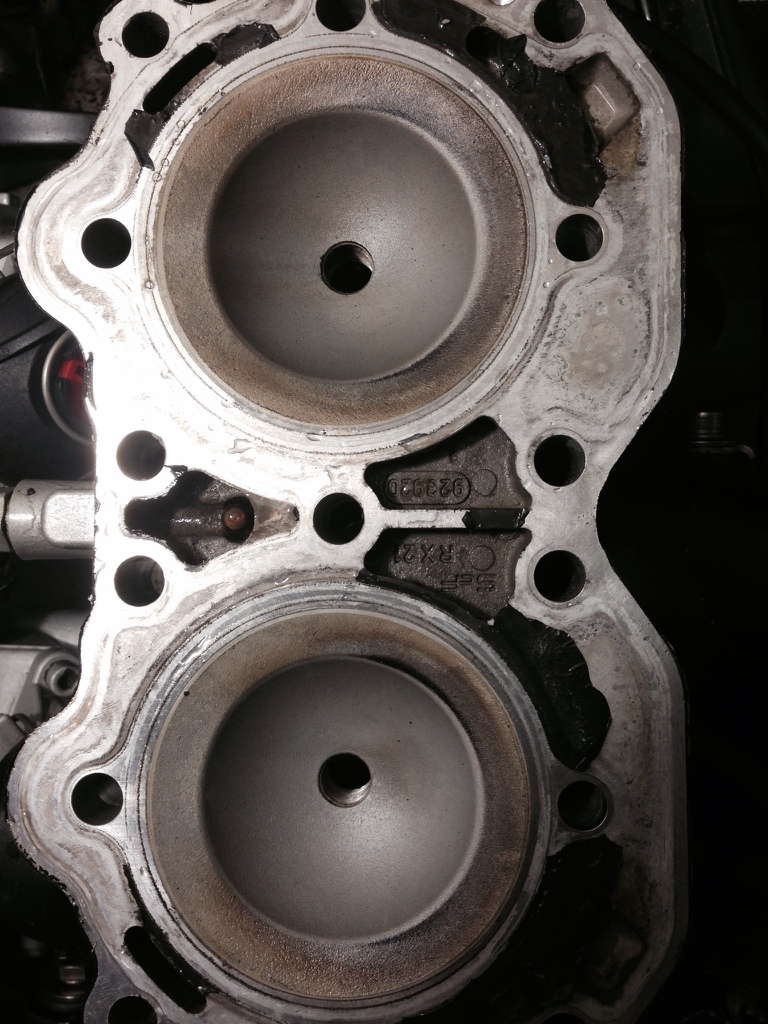

2 gaskets

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

You have a plastic dead blow hammer and a rubber mallet handy? Gently tap on the outside contour of the head to loosen the gasket seal from below and on the sides.

Chisel helped

Sent from my iPhone using Tapatalk

Sportster-2001-951C-Stock

Well-Known Member

Hey Sportster, what if we bank it together and see whose blows up first :cheers:

I'm willing to discuss this possibility, I've been considering the purchase of a spare motor.

Bonmotwang

Well-Known Member

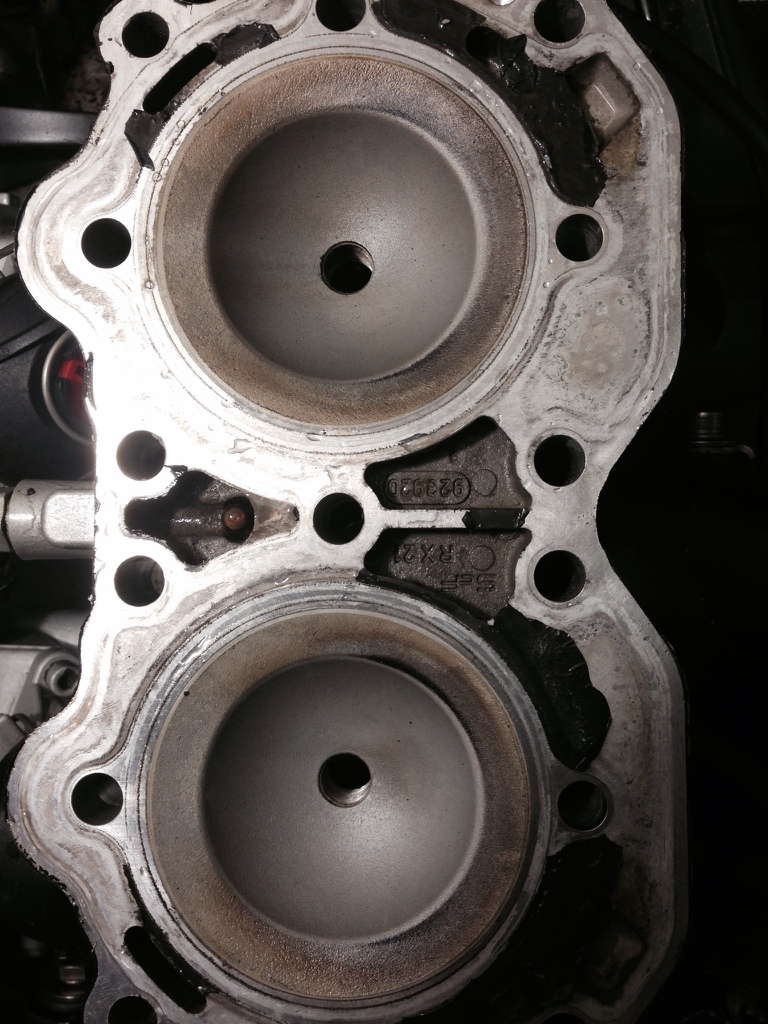

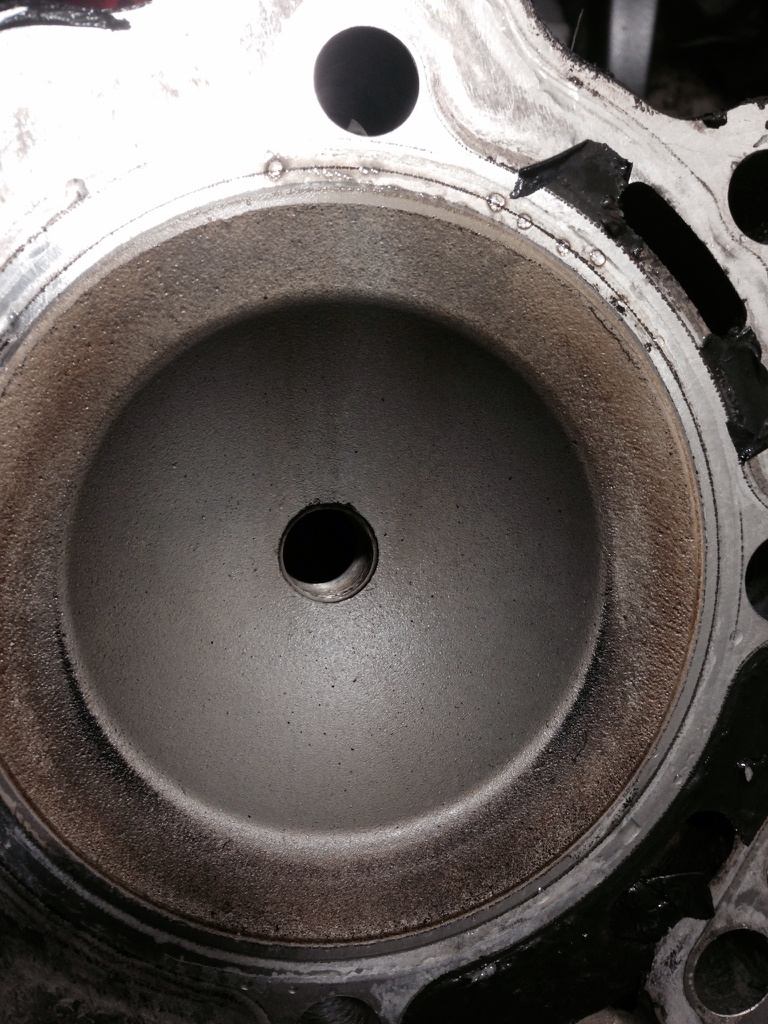

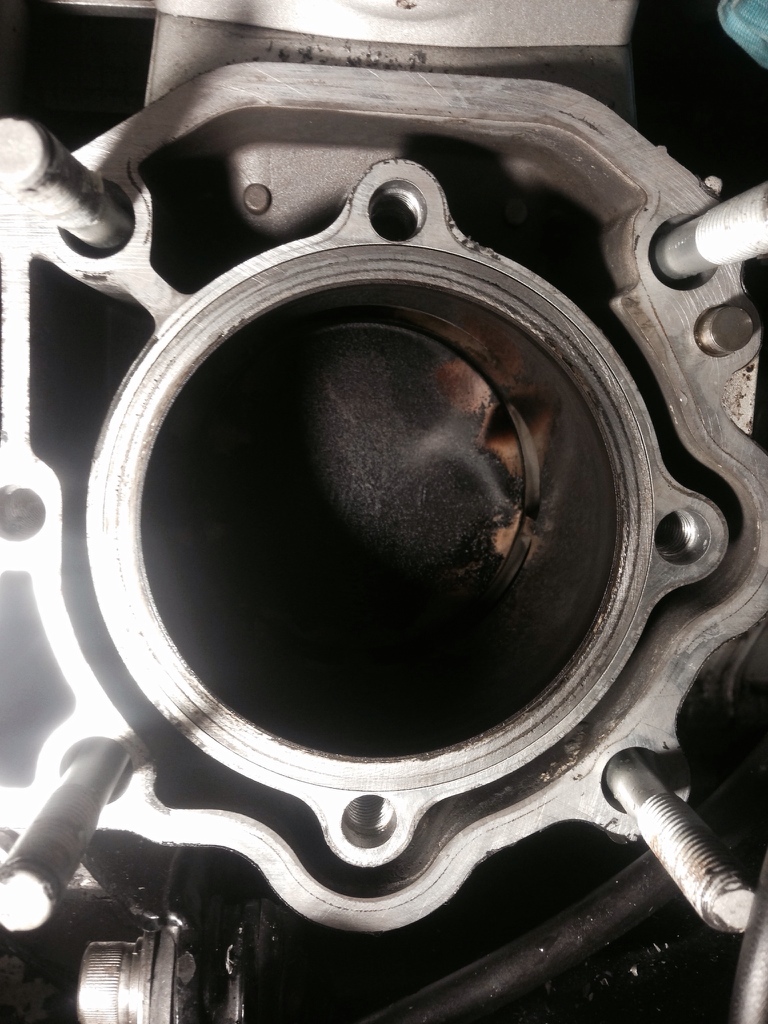

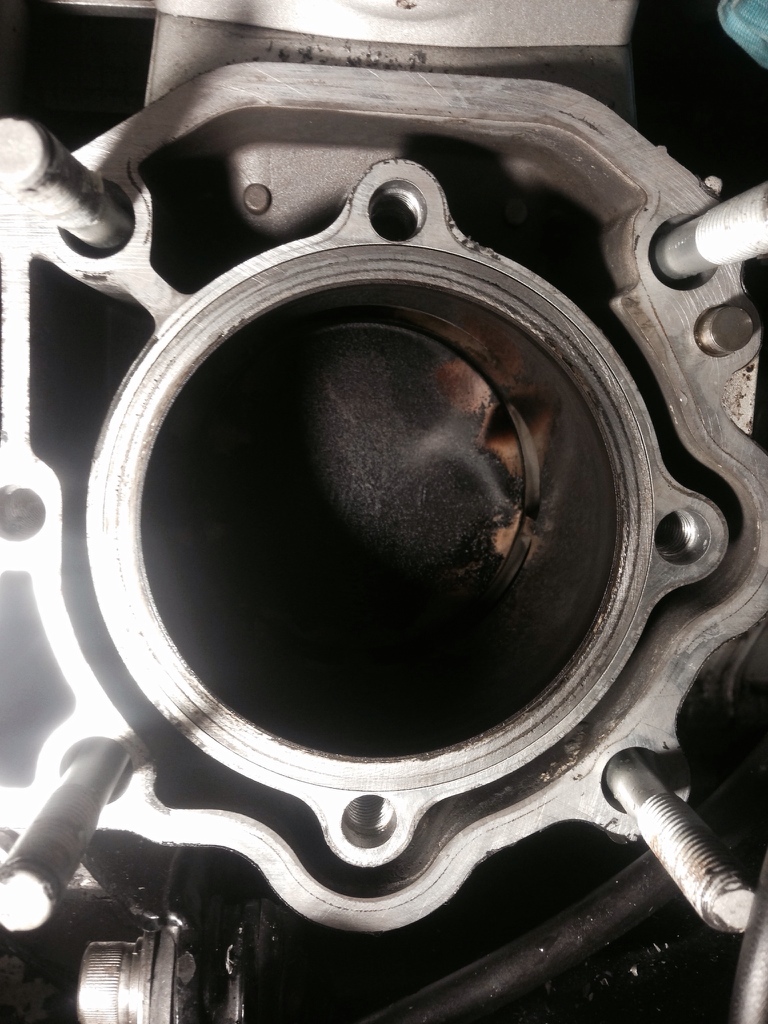

Opened.

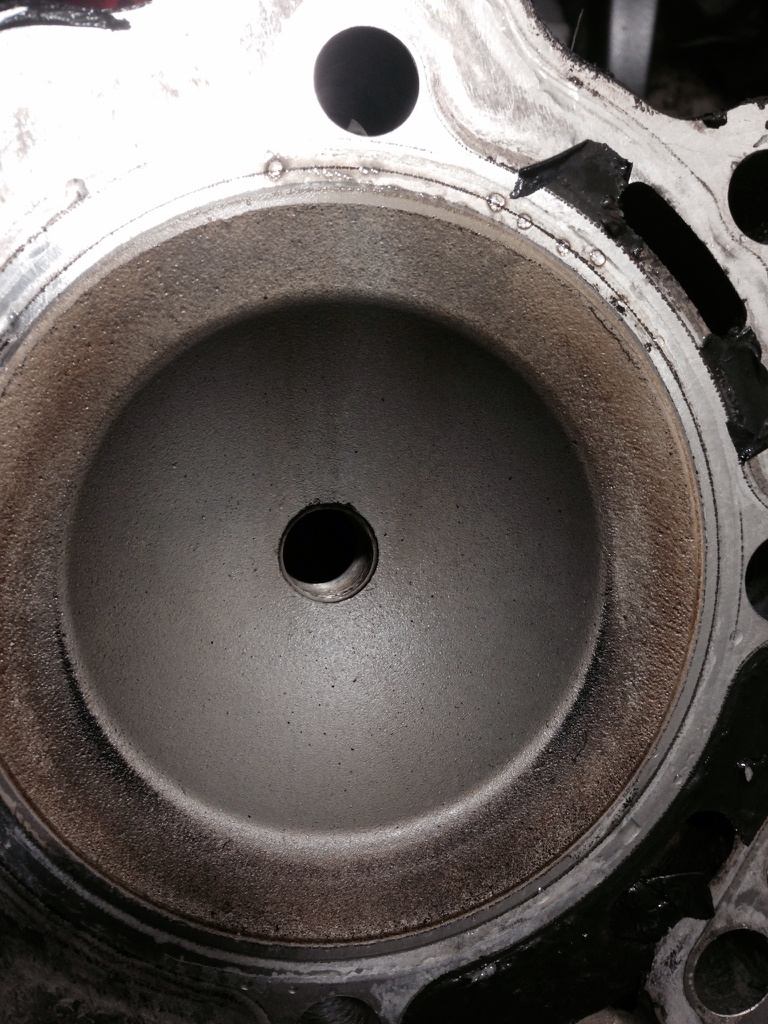

Both cylinders same condition. Pretty smooth and shiny, I touched by hand, couldn't feel anything.

What is the next step?

Edit: taking a break and eating a pear right now.

Sent from my iPhone using Tapatalk

Both cylinders same condition. Pretty smooth and shiny, I touched by hand, couldn't feel anything.

What is the next step?

Edit: taking a break and eating a pear right now.

Sent from my iPhone using Tapatalk

Last edited by a moderator:

Sportster-2001-951C-Stock

Well-Known Member

I think this gasket is a laminated type.

Bonmotwang

Well-Known Member

I think this gasket is a laminated type.

It feels like metal to me.

Sent from my iPhone using Tapatalk

Waterluvr

New Member

It looks like the piston edges have been working the same way a self cleaning oven has, lot of carbon has been burned off the edges. Head looks good, that's a really good start.

I'm looking at the SD parts diagram, they show an image that appears to be a caged wrist pin bearing so that's a plus

I'm looking at the SD parts diagram, they show an image that appears to be a caged wrist pin bearing so that's a plus

Sportster-2001-951C-Stock

Well-Known Member

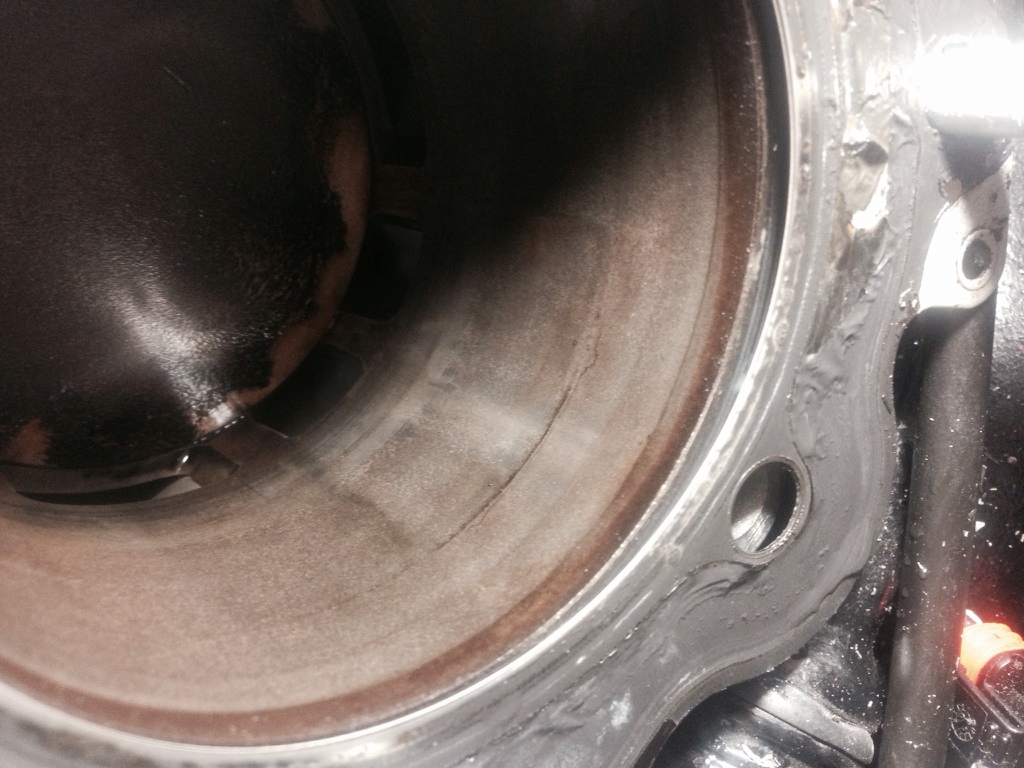

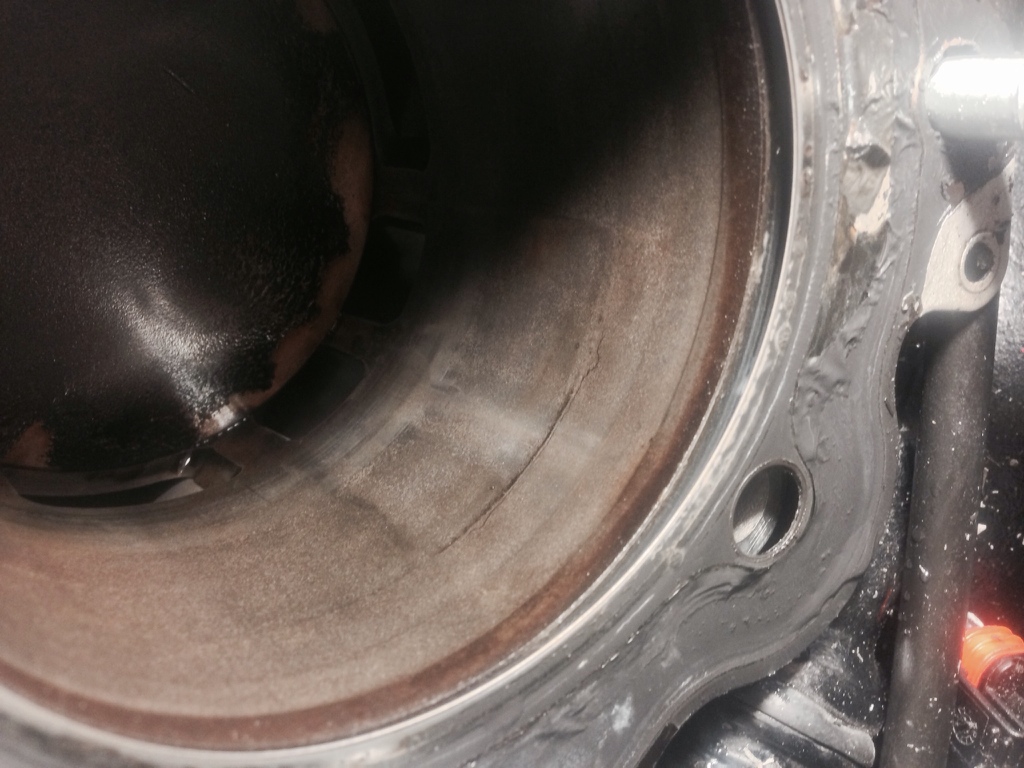

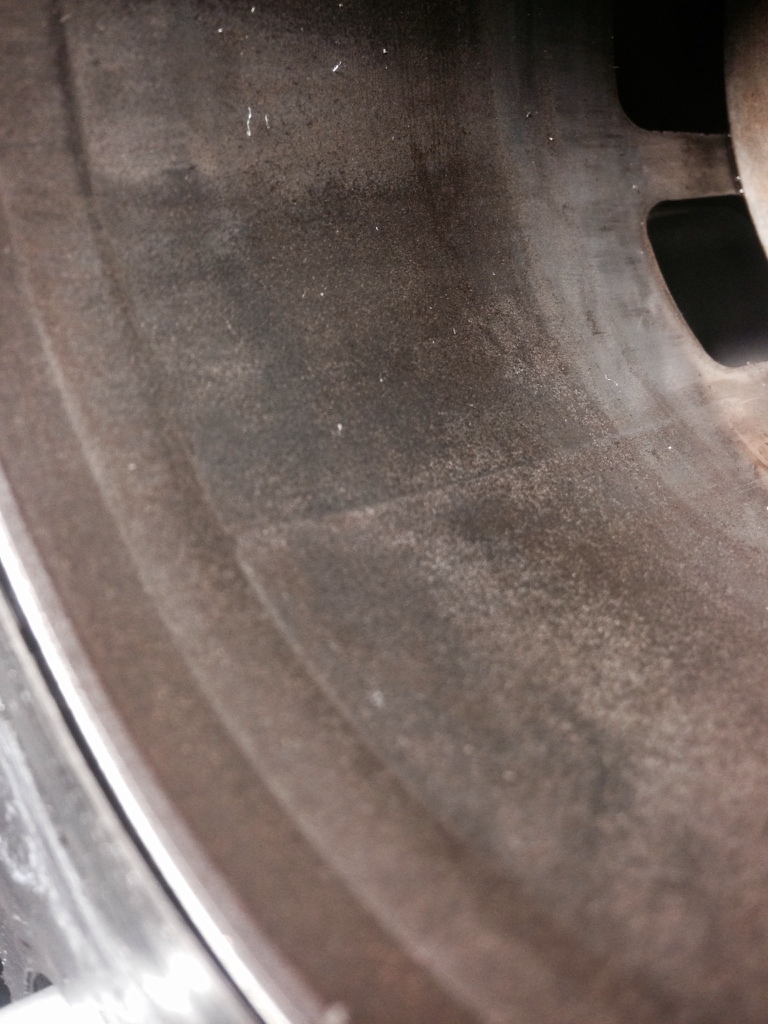

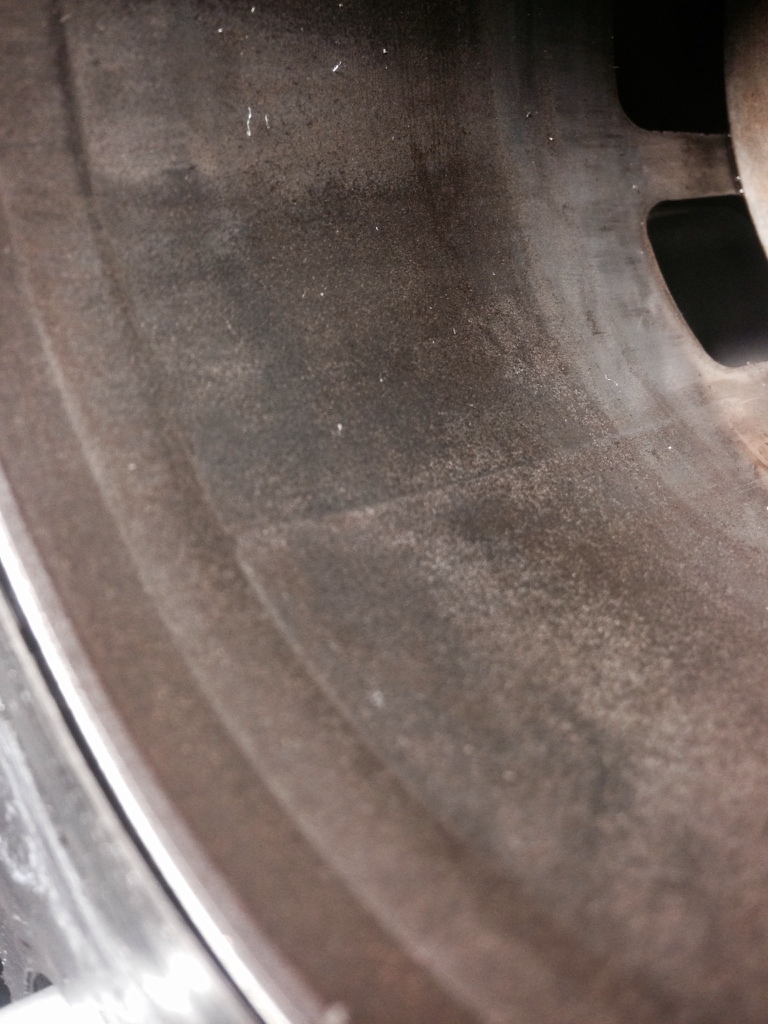

Is that some pitting in the cylinder walls? If yes, I blame this on corrosion.

Is there a ridge you can feel at the top where the rings reverse direction? If yes, this represents cylinder wear near the top.

Is there a ridge you can feel at the top where the rings reverse direction? If yes, this represents cylinder wear near the top.

Waterluvr

New Member

Is that some pitting in the cylinder walls? If yes, I blame this on corrosion.

Is there a ridge you can feel at the top where the rings reverse direction? If yes, this represents cylinder wear near the top.

It sure looks that way, hopefully the next size up on the boring bar will take that out. ~He takes some seriously good pics!

Bonmotwang

Well-Known Member

It sure looks that way, hopefully the next size up on the boring bar will take that out. ~He takes some seriously good pics!

I will wipe of the oil and take some more pictures. The some of the pitting lines are the oil. Hold on.

Bonmotwang

Well-Known Member

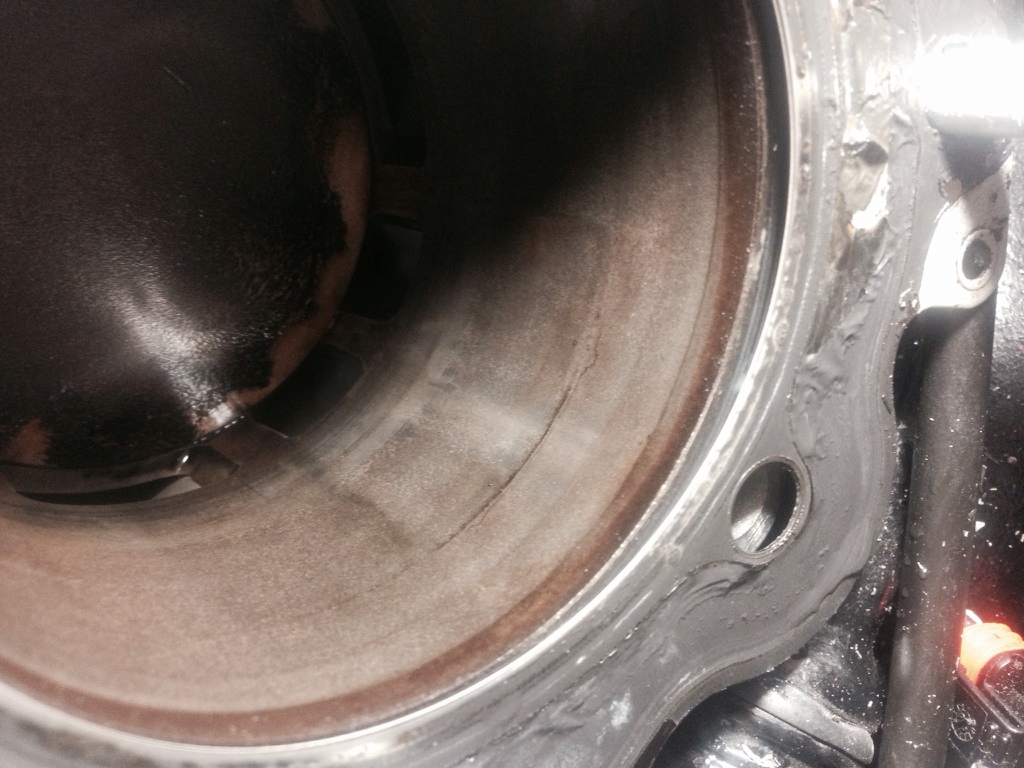

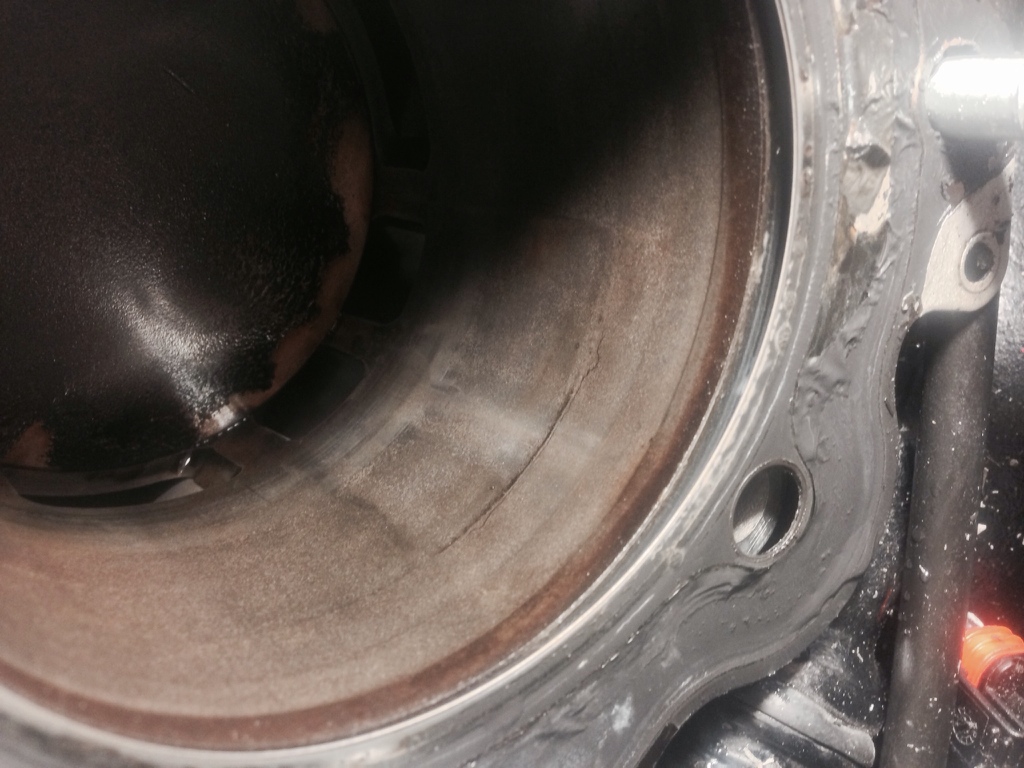

This is PTO side. You can see 3 lines. And I can feel them too. Is the vertical one the ring gap?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Sportster-2001-951C-Stock

Well-Known Member

It feels like metal to me.

Sent from my iPhone using Tapatalk

Yes, it is a metal gasket that has a coating, looks like it's laminated layers.

Bonmotwang

Well-Known Member

Removed the gasket. The water jacket is very clean.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Sportster-2001-951C-Stock

Well-Known Member

The ring gap is located between the ports, it cannot be exposed to any port or the end of the ring will snag inside the port.

Bonmotwang

Well-Known Member

Mag side 3 lines. The top ring pitting line is deeper than the PTO side, the vertical line almost hard to see. I had to adjust the shooting angle to capture it.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Waterluvr

New Member

Your next step when you're ready is to slide the cylinders up and off the pistons. You need to break the seal of the base gasket and your plastic dead blow mallet is a good way to do this. Or a block of wood and light taps with like a one pound hammer around the base and corners. Be careful and avoid prying up on anything.

Bonmotwang

Well-Known Member

The ring gap is located between the ports, it cannot be exposed to any port or the end of the ring will snag inside the port.

Right on. Two lines are at exactly same angle and between two ports.

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

Did another check. Moved the piston to the top and push side ways by hand. It has about 0.030" play. And I can see the top ring stays right with the cylinder.

So the rings are not seized?

Same as the other piston.

Sent from my iPhone using Tapatalk

So the rings are not seized?

Same as the other piston.

Sent from my iPhone using Tapatalk

Bonmotwang

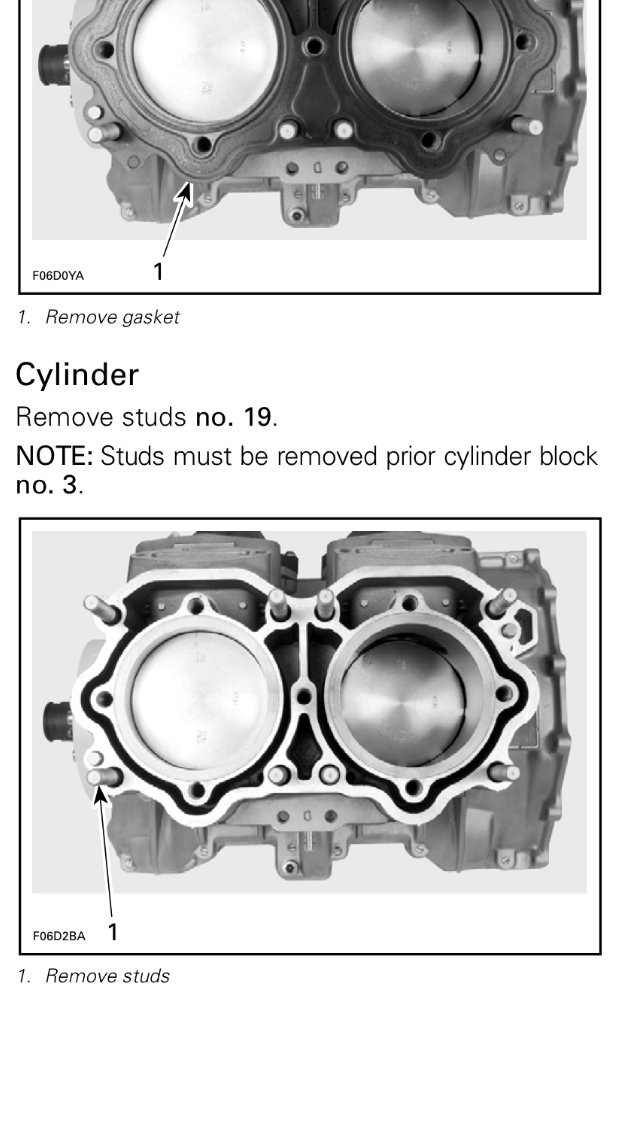

Well-Known Member

Your next step when you're ready is to slide the cylinders up and off the pistons. You need to break the seal of the base gasket and your plastic dead blow mallet is a good way to do this. Or a block of wood and light taps with like a one pound hammer around the base and corners. Be careful and avoid prying up on anything.

Manual said you have to remove the rods/studs before remove the cylinder.

Sent from my iPhone using Tapatalk

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 220

- Replies

- 7

- Views

- 653

- Replies

- 3

- Views

- 348