Bonmotwang

Well-Known Member

Yes, you can spray WD-40, there will be no damage.

I suspect the studs were installed using lock-tite red so it may be necessary to heat them using a torch to soften the lock-itte.

I think you should be able to lift the cylinder assembly while the head studs are still installed, I don't understand why seadoo says you cannot..

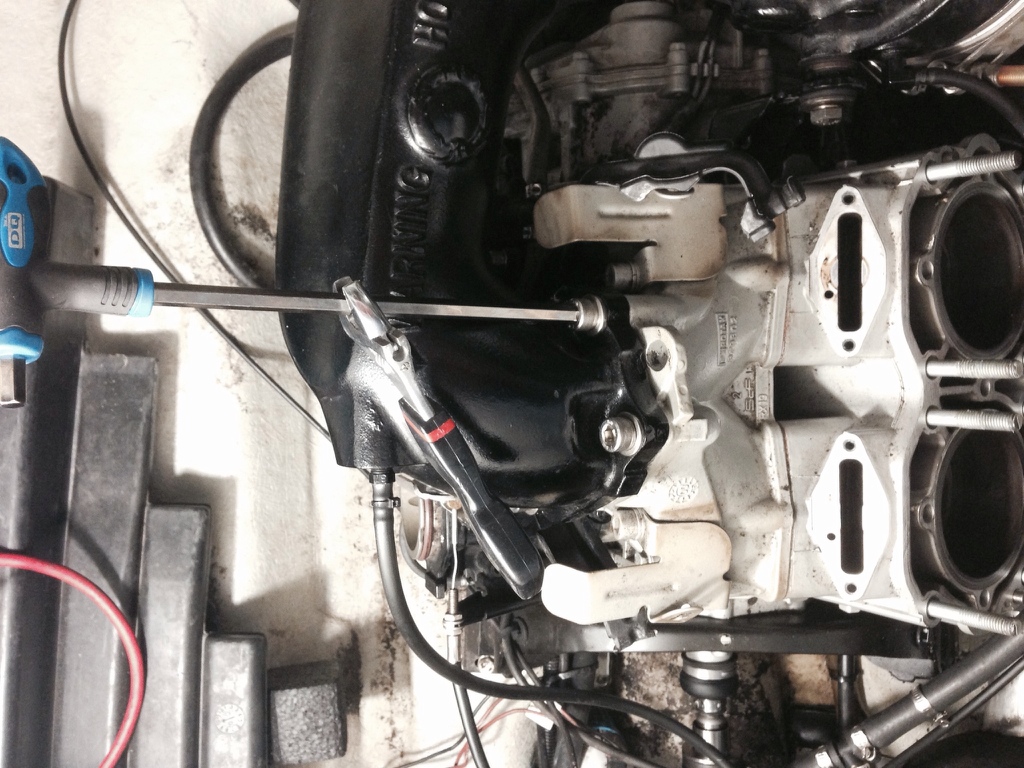

Ok. Soaked in

Sent from my iPad using Tapatalk