I didn't do any blow out last fall :-(

*Always turn the water off first, 30 seconds before turning off motor. You can hear the exhaust tone change as the water is blown out by the pressure, it gets slightly louder.

I only poured a lot of anti freeze in.

* You should do this, I pinched the block drain using forceps and poured in 2 quarts of 100% -50* antifreeze then stopped when it came out the flush port. Then removed the forceps from pinching the block drain. There shouldn't be much water in there if you ran the motor 30 seconds no hose but a small amount is always trapped and so it's necessary to pour in some antifreeze to be safe. It's impossible to remove all the water and completely dry the exhaust so it's important to fog/oil the motor well to prevent corrosion in the cylinders due to residual moisture in the exhaust, the cylinder sleeves are iron and rust quickly, rust is no bueno.

I did run the engine for 15 second twice today without hose.

* You can actually run it longer(if it's running correctly) but I recommend 30 seconds to be safe, I found it's enough time to blow most of the water out of the exhaust. Oiling your motor helps reduce corrosion further, always oil your motor, never forget it must always have oil or damage will occur. If you see oil smoke, for sure it's enough oil. If you don't see oil smoke, there may not be enough oil. Oil going in is the only lubricant it receives, this oil eventually leaves through the exhaust then there is no lubricant remaining. At low throttle position like idle, the oil pump delivers NO oil.

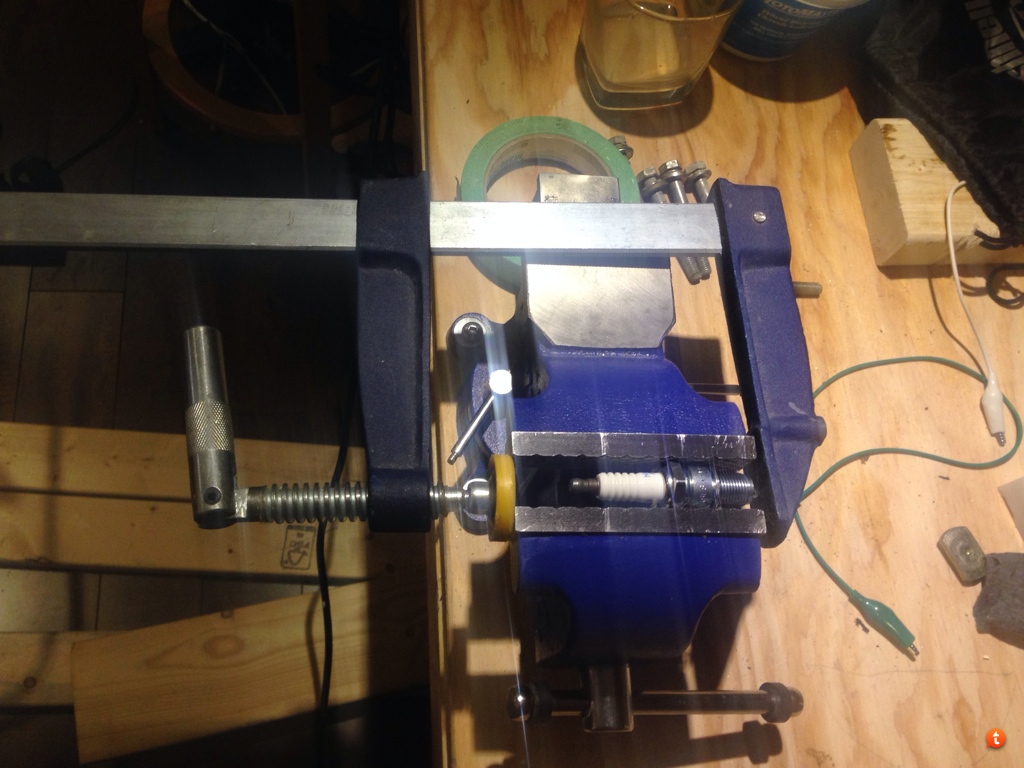

I didn't replace the spark plugs. I will check the gap. But I did test the plugs out of the engine when cranking, they arced well.

*Just b/c you see spark with plugs out doesn't mean they will spark while in, the conditions are more severe with compression, the voltage must rise higher to jump the gap. This is why the gap is just 0.020" Also, you may have a dry carburetor, make a squirt bottle of 32/1 fuel mix and give the dead cylinder a shot of this while the engine is running (don't use straight gasoline, there is no lube, remember you always need lube), if the cylinder begins firing by adding fuel (you can hear the improvement), the carb is likely gummed and needs rebuilding. Otherwise change the plugs, changing plugs when one cylinder is dead is always the first action to take b/c most often that's the problem (all of this is assuming the engine is in good condition and compression is normal).

The low RPM explained why it always stop when I pull the throttle back to switch from neutral to forward.

*I think you must mean this happened while in the water.

Can I verify "only one cylinder is working" by unplug one of the spark wires out and to see if there is difference?

* I prefer to feel the warm plug from the heat of fire, the cold plug is misfiring. If the cylinder compression is low, it may not ever fire. If the spark plug is new then squirt some premix 32/1 in the carb and see if the cylinder begins firing. If it beings to fire, the carb is gummed and needs rebuild.

Also I found out the pipe support 274000878 is broken. Maybe from the vibration?

*Hmm, I hear this is common.

I will do the compression again tonight and report.

*Thanks, I hope they are both near 120psi or more.

Thanks guys, without you guys, I am no where even close to be where I am right now. May have already given up

*No problem, I think you have more work ahead of you though.

Sent from my iPhone using Tapatalk[/QUOTE]