Yes, you should be able to turn the PTO by hand until compression is too great to overcome, the motor usually stops with both exhaust ports open, common for 2cyl 2 stroke motor, so maybe you can easily rotate maybe 20 degrees before compression is felt.

Umm, did you oil-fog your motor last fall and allow the water to blow out the exhaust while running 30 seconds more? You should see a nice cloud of smoke. Then after stopping motor remove plugs, they should be wet with oil.

Now you should remove the spark plugs and be able to spin the motor 360 degrees by hand. If you hear scraping sounds it's likely some cast iron cylinder corrosion, give her some oil in both spark plug holes. A 1/2 ounce per cyl is enough, then lay a rag over the plug holes and crank by the electric starter to blow out any excess oil.

For spline grease, my testing indicates grease worms like thin grease best so I use thickest available b/c they eat it slowly. I use marine trailer bearing grease on my PTO spline, I think about any grease will absorb water though? I know waterproof marine grease does absorb water, judging by the color. Thickest formula will remain longest I think, Extreme Pressure type always.

Also, any grease is better than no grease (just ask any grease worm!)

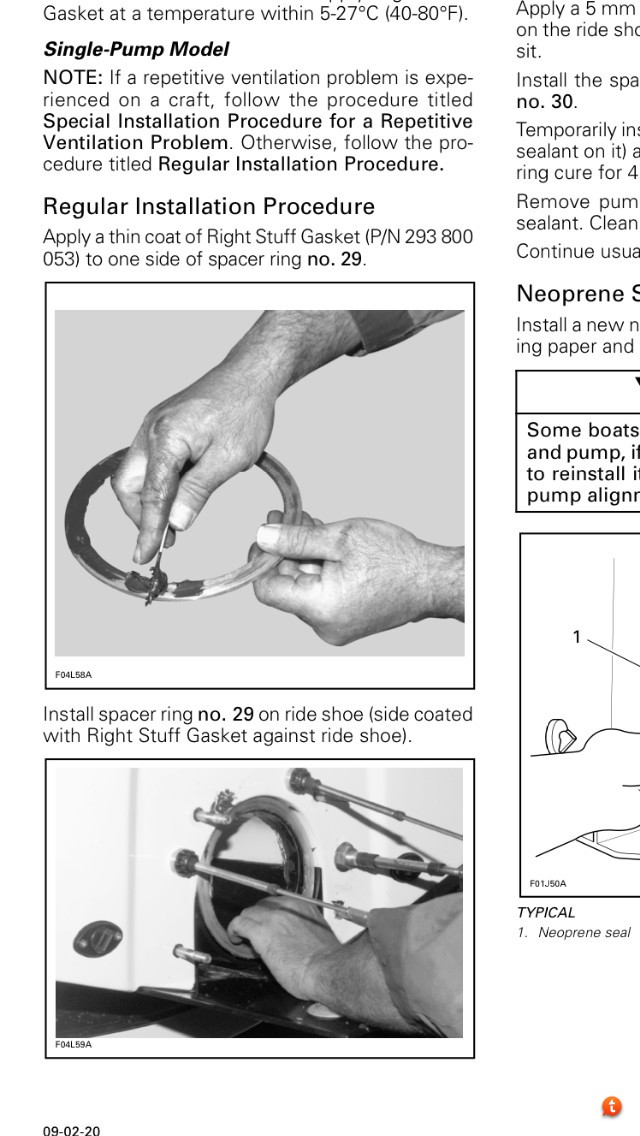

My boat uses a neoprene seal like yours, looks like you installed it correctly.

Guess where I was today?