I did some measurements and closer inspection to make sure I am making the right decision:

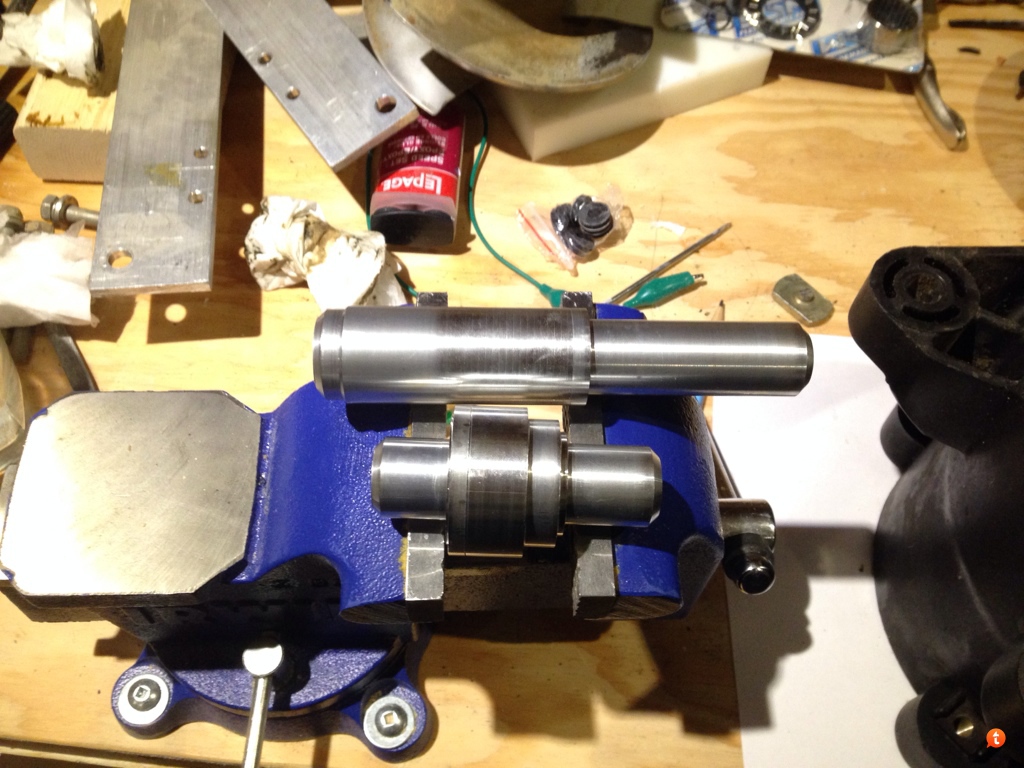

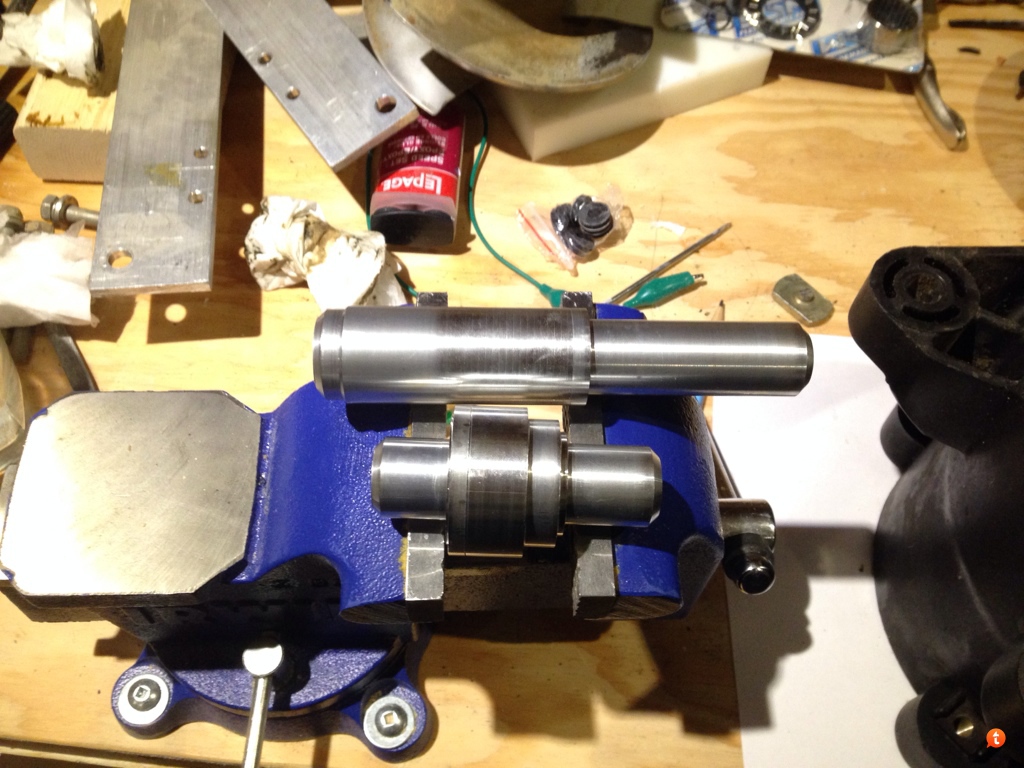

The shaft measures 22.26mm in the middle, 22.25/22.26mm at the needle bearing location. The minimum should be 22.24mm according to the manual.

So i think other than some dings on the surface, overall dimension is OK.

When I looked closely to the thrust bearing and thrust washer I found more dings on the bearing and washer, much worse than the needle bearings. I looked into the needle bearings with a flash light, they look pretty good on the surface. I attached a few pictures of the thrust bearing and the washer to show the wear.

I got the rebuild package anyway, so I will replace the thrust washer and bearing.

As Sportster-2001-951C-Stock has pointed out, the grooves I found on the shaft is not at the needle bearing contact area. They are where the seal contacts the draft. But I guess I will leave it for now and inspect the oil after a few hours run.

I guess my next step is to put together what I have on the bench and start testing the engine with a garden hose.

I need some suggestions here:

I want to clean up the bearing housing to make sure I got most of the metal debris out. I have a pressure washer, but I guess this is a bad idea? :facepalm:

What should I use to wash the bearing housing and the needle bearings in place?

Thanks.