-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2001 Seadoo Sportster LE. Just got it!

- Thread starter Bonmotwang

- Start date

- Status

- Not open for further replies.

Bonmotwang

Well-Known Member

Man! All this boat talk makes me want to start on my floating projects. I've been on a home/car improvement kick lately. Basically tending to all those neglected things I left off because it was boating season and way too nice out to do WORK in my free time

I am just looking at the parts. For about 15 minutes now lol.

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

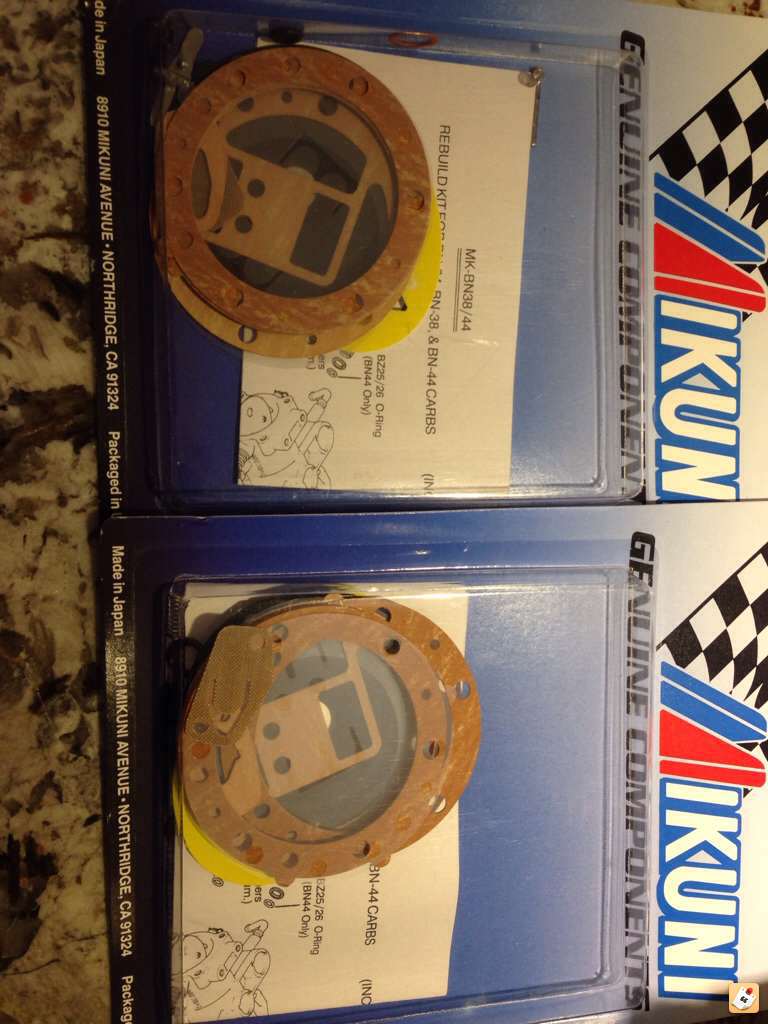

hmmm those carb kits look suspect to me... Did they include the round-body gaskets with the new mikuni kits? The round bodies are the pre-90's cousins of our modern carbs. Lol modern and carbs don't really belong in the same sentence but you know what I mean.

You are right! It is the wrong one. I have contacted the seller. I hope I don't get dragged into "ship the parts back" hassle.

Bonmotwang

Well-Known Member

You are right! It is the wrong one. I have contacted the seller. I hope I don't get dragged into "ship the parts back" hassle.

The seller responded right away. The new/correct parts are on the way. Seller is going to pay for the shipping for the wrong to go back.

All good ...

Bonmotwang

Well-Known Member

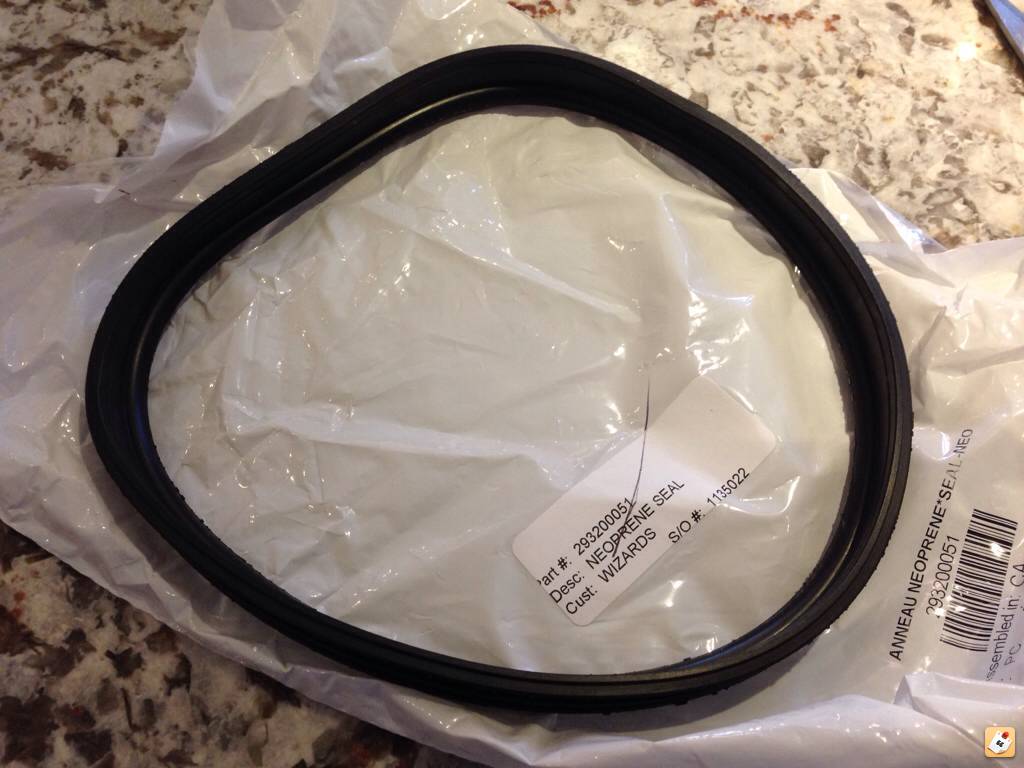

Hello folks. I am back to the job. I thought it was a winter project. But now it is spring. LoL. Haven't done anything in last 5 months. I got all the tools and parts for rebuilding the jet pump and the carbonators if necessary. I guess I should take out the propeller first then take the ring out? I did try put the whole pump in my freezer for 12 hours, but the ring is still very tight.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

FinnExplorer

Active Member

I believe the freezing process is meant for installing the new wear ring. You have to use the impeller tool to take off the impeller and then carefully cut through the old wear ring. Maybe cut two lines and remove the piece in between them. Then somehow(use your imagination here  ) wiggle the rest out. Then you can take the new ring from freezer and slide it in

) wiggle the rest out. Then you can take the new ring from freezer and slide it in

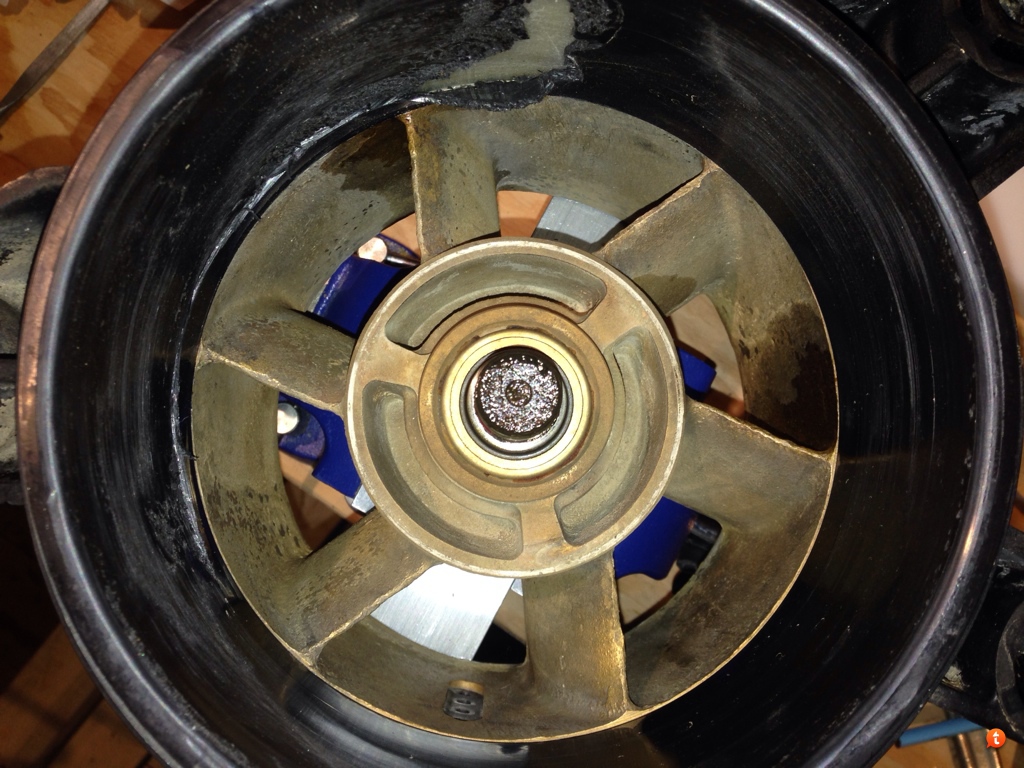

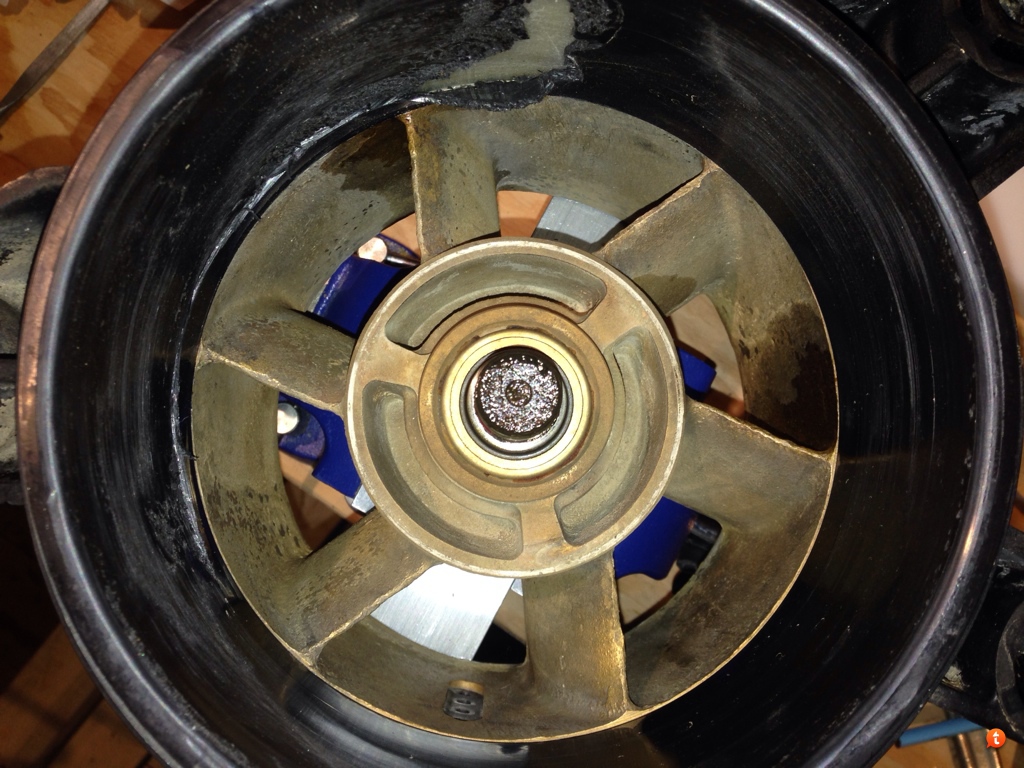

I'm not a expert here but your impeller looks like it's seen a lot of rough times. Pretty dented on the edges.

I'm not a expert here but your impeller looks like it's seen a lot of rough times. Pretty dented on the edges.

Bonmotwang

Well-Known Member

Thanks. I may have mixed things up. :-D

I will take off the propeller first then cut off the old ring.

Sent from my iPhone using Tapatalk

I will take off the propeller first then cut off the old ring.

Sent from my iPhone using Tapatalk

FinnExplorer

Active Member

Not trying to be a smart ass but

Propeller vs Impeller

While a propeller is designed to covert rotational motion into forward thrust, an impeller is designed to use rotational motion to suck fluid in.

A propeller has an open design while an impeller is always inside a casing or housing.

Cheers! Have a nice friday night :cheers:

Propeller vs Impeller

While a propeller is designed to covert rotational motion into forward thrust, an impeller is designed to use rotational motion to suck fluid in.

A propeller has an open design while an impeller is always inside a casing or housing.

Cheers! Have a nice friday night :cheers:

Bonmotwang

Well-Known Member

Thanks for the correction. Very Accurate definition.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Sportster-2001-951C-Stock

Well-Known Member

Yep, sometimes it's possible to remove the wear ring using a rod and mallet from the outlet side to knock it out the inlet but if you're planning on new bearings/shaft/seal anyway then removing the impeller is necessary anyway. Easier to damage pump veins, etc. by trying to knock it out from the outlet nozzle, kinda risky.

You may have to cut the original wear ring using a hack saw blade or dremel in a few places to get it lose enough to remove.

Freezing the new wear ring will cause it to shrink a bit and possibly drop into place if it's too tight to insert at room temp.

Sometimes a new wear ring can be tight around the circumference of the impeller, so consider getting the motor running (well) again before installing the pump and drive shaft, an easy to start engine will expedite the process of lapping the new ring to the impeller (some liquid dish soap or light oil on the ID of the ring helps lubricate the impeller blades and reduce the friction as well, during the wear ring lapping process).

You may have to cut the original wear ring using a hack saw blade or dremel in a few places to get it lose enough to remove.

Freezing the new wear ring will cause it to shrink a bit and possibly drop into place if it's too tight to insert at room temp.

Sometimes a new wear ring can be tight around the circumference of the impeller, so consider getting the motor running (well) again before installing the pump and drive shaft, an easy to start engine will expedite the process of lapping the new ring to the impeller (some liquid dish soap or light oil on the ID of the ring helps lubricate the impeller blades and reduce the friction as well, during the wear ring lapping process).

Bonmotwang

Well-Known Member

Are you saying I can work on the engine without the pump on it? I guess I have to remove the drive shaft, otherwise it will became a weapon. do you think I really need to do the carb? I did have the rebuild kit.

I think what I should do is rebuild the pump first. And take the drive shaft from the engine, recharge the battery, test the engine with garden hose without the pump. And report the result here.

Sent from my iPhone using Tapatalk

I think what I should do is rebuild the pump first. And take the drive shaft from the engine, recharge the battery, test the engine with garden hose without the pump. And report the result here.

Sent from my iPhone using Tapatalk

Last edited by a moderator:

Sportster-2001-951C-Stock

Well-Known Member

Yes, you can run the engine while the drive shaft is removed, with or without water (make as necessary, plumbing connections if using cooling water). Of course no water is necessary if running time is kept short (~30 seconds). The only danger of running without pump and drive shaft is, if the PTO wheel unscrews from the threaded crankshaft (a possible rotating hazard can occur) but this shouldn't be a problem for a used engine b/c the PTO will already be tightly threaded onto the crankshaft by historical torque, still, beware of the potential rotating hazard.

Whether or not to rebuild the carbs first depends on how well the engine starts, if the carbs are working well already the engine should start easily (I think you can test this before installing the drive shaft). Of course if the engine has not been started in 5 months, it will naturally be more difficult to start at first b/c the normally residual fuel will have evaporated from within the crankcase over the period.

For instance, I started my engine last weekend for the first time since October and it required a bit of extra cranking(with choke applied) b/c the fuel had evaporated from the carbs and crankcase, I also had drained the fuel tank and the fuel lines were most likely dry as well.

Seems like many new wear rings are tight around the circumference of the impeller, causing difficulty starting the engine. So if the engine is hard to start already (b/c it hasn't been started in 5 months) even without the extra friction, then it may be impossible to start once the tight pump is reinstalled.

Whether or not to rebuild the carbs first depends on how well the engine starts, if the carbs are working well already the engine should start easily (I think you can test this before installing the drive shaft). Of course if the engine has not been started in 5 months, it will naturally be more difficult to start at first b/c the normally residual fuel will have evaporated from within the crankcase over the period.

For instance, I started my engine last weekend for the first time since October and it required a bit of extra cranking(with choke applied) b/c the fuel had evaporated from the carbs and crankcase, I also had drained the fuel tank and the fuel lines were most likely dry as well.

Seems like many new wear rings are tight around the circumference of the impeller, causing difficulty starting the engine. So if the engine is hard to start already (b/c it hasn't been started in 5 months) even without the extra friction, then it may be impossible to start once the tight pump is reinstalled.

Bonmotwang

Well-Known Member

The shaft remover fits very very well. An accurate tool.

I was going to mount the other end of the shaft on the vise directly and unscrew the impeller. But after checking the manual, I think I better to make the shaft holder as shown in the attachment. I think this will prevent the shaft from being bent by the unscrewing force?

Heading out to canadiantire to get a piece of aluminum. Drill press and files should do the job

I was going to mount the other end of the shaft on the vise directly and unscrew the impeller. But after checking the manual, I think I better to make the shaft holder as shown in the attachment. I think this will prevent the shaft from being bent by the unscrewing force?

Heading out to canadiantire to get a piece of aluminum. Drill press and files should do the job

Bonmotwang

Well-Known Member

Found some alum bars left over from my desktop CNC :-D

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

One thing always leads to another :-D

The 4 mounting screws don't have enough thread to hold the shaft holder. Felt lucky in my tool box, I found two will do the job.

Sent from my iPhone using Tapatalk

The 4 mounting screws don't have enough thread to hold the shaft holder. Felt lucky in my tool box, I found two will do the job.

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

Ok. Made up the shaft holder. No bad hah.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

I'm not a expert here but your impeller looks like it's seen a lot of rough times. Pretty dented on the edges.

You are right. This 155mm impeller has a lot of chips on the edge. The part number for my boat is 204160136 according to the manual. About $300 for a new one. So try not to replace it :-D.

Unbalance is the biggest enemy I think.

After I take off the impeller, I will double check the p/n, and take a closer look.

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

Got the socket set and torque wrench from Lowes. The wrench is huge! After I took off the impeller i am 100% convinced that better to have the shaft holder to hold the other end. Because it IS tight!

The impeller is actually not bad. I am attaching some closer shots here. The part number is the stock part number 204160136 as shown in the picture.

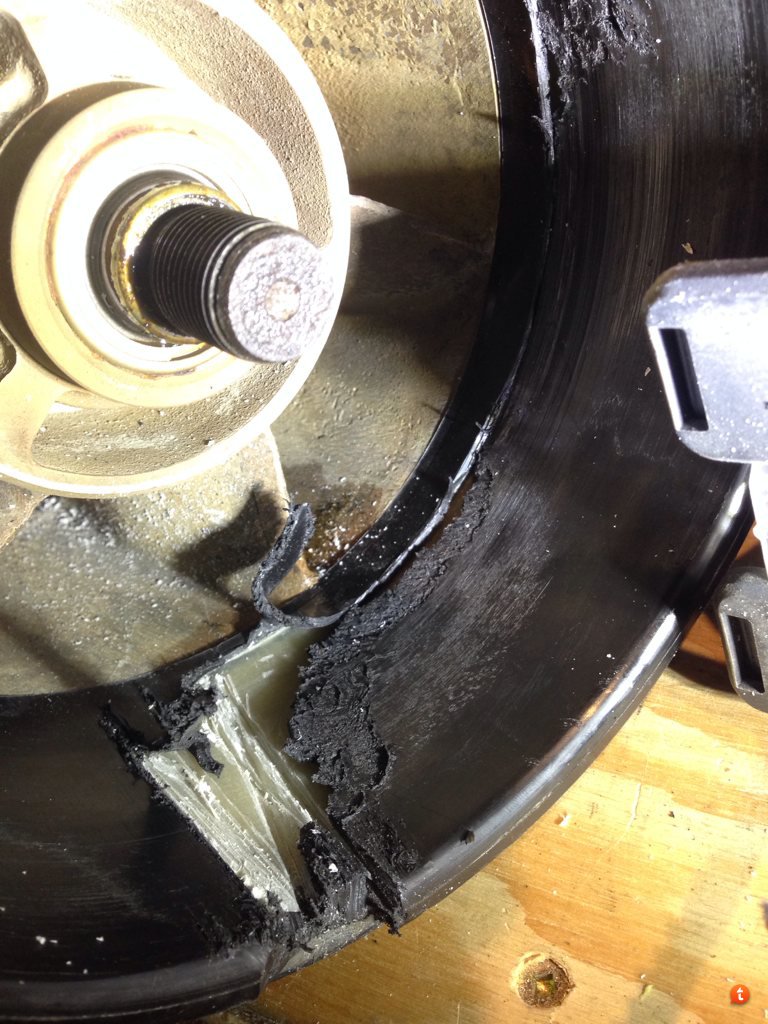

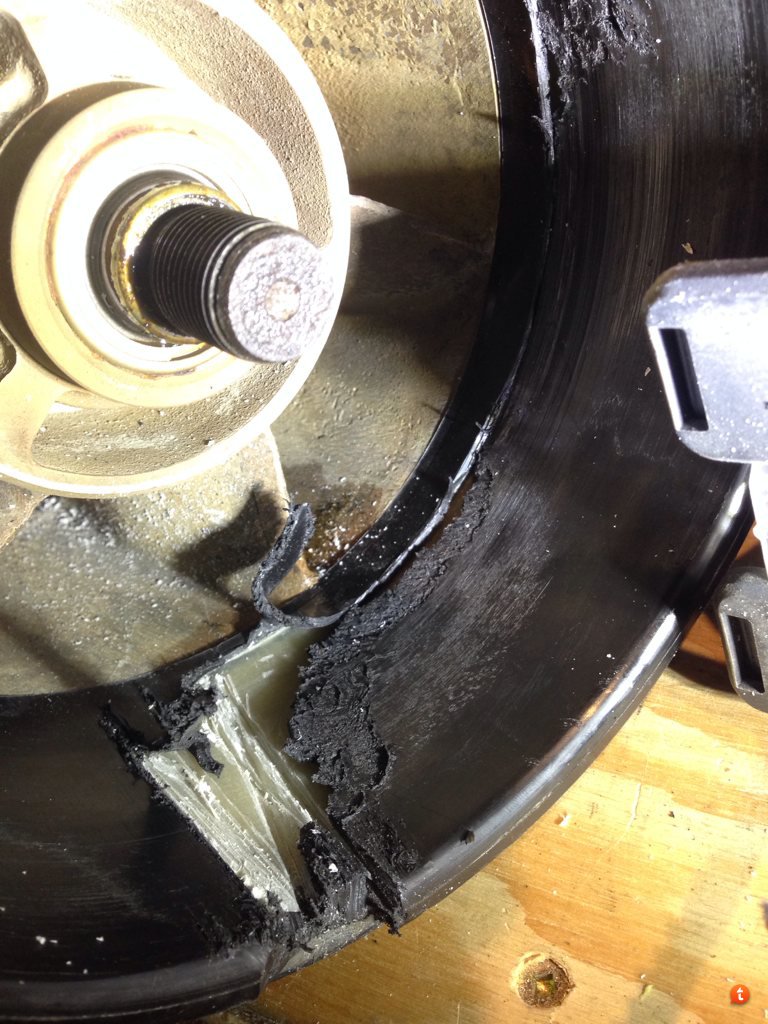

Also I almost made a mistake: I was trying to separate the wear ring black part and the white inner part. After 2 minutes of trying i realized that they both belong to the old wear ring. LoL

Sent from my iPhone using Tapatalk

The impeller is actually not bad. I am attaching some closer shots here. The part number is the stock part number 204160136 as shown in the picture.

Also I almost made a mistake: I was trying to separate the wear ring black part and the white inner part. After 2 minutes of trying i realized that they both belong to the old wear ring. LoL

Sent from my iPhone using Tapatalk

Sportster-2001-951C-Stock

Well-Known Member

Good job man, I think your pump will work great when finished!  Does the shaft seem to have any wear on the bearing surfaces?

Does the shaft seem to have any wear on the bearing surfaces?

Last edited by a moderator:

Bonmotwang

Well-Known Member

Can i just pull the shaft out? I am using jig saw cutting the wear ring now. Very slowly, trying not to cut through the housing. :-D.

Is the house at wear ring part only plastic??

Sent from my iPhone using Tapatalk

Is the house at wear ring part only plastic??

Sent from my iPhone using Tapatalk

Sportster-2001-951C-Stock

Well-Known Member

Give the threaded end of the shaft a blow using a plastic or rubber mallet, should slide out.

The original wear ring is laminated plastic layers I believe, look at dimensions of new wear ring to get an idea of how deep and long to cut the original for removal.

Also, it appears your pump is bronze, so shiny chips of bronze will tell you to move your saw?

The original wear ring is laminated plastic layers I believe, look at dimensions of new wear ring to get an idea of how deep and long to cut the original for removal.

Also, it appears your pump is bronze, so shiny chips of bronze will tell you to move your saw?

Last edited by a moderator:

Bonmotwang

Well-Known Member

It just slid out. I took some pictures. I can see and feel wear on one end.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

With vise grips help I got the wear ring out. Didn't hurt the housing. But after I took the ring out, I found two big cuts into the housing by previous replacing work. Very sad. Not sure if I need a housing now :-(

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Bonmotwang

Well-Known Member

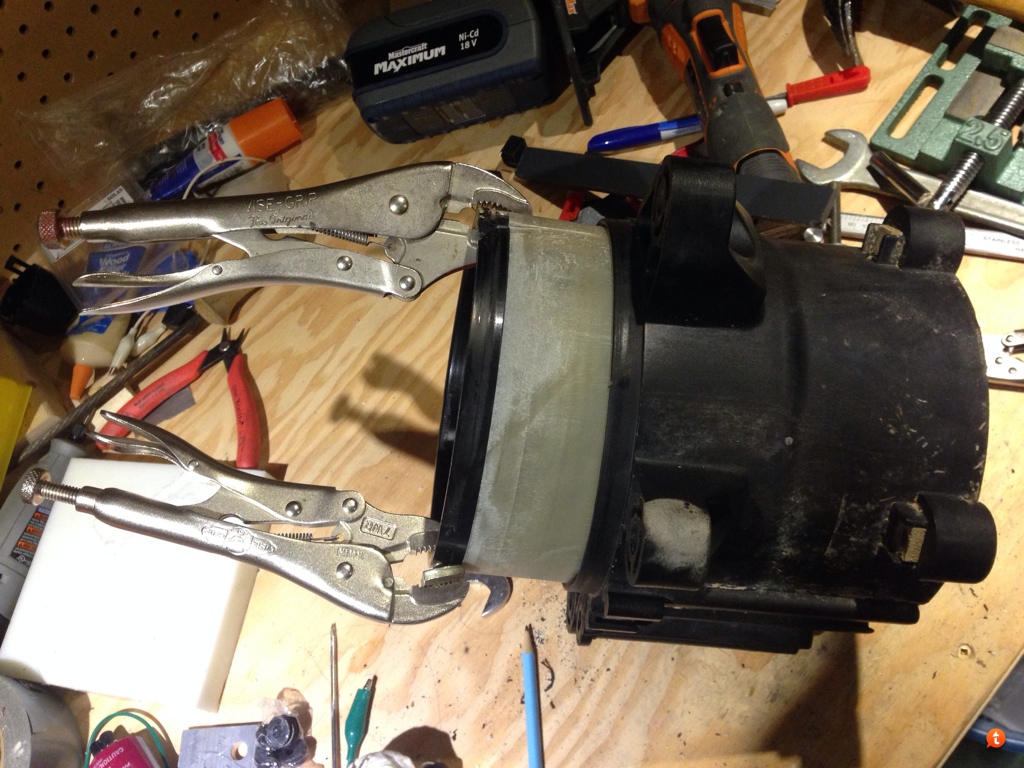

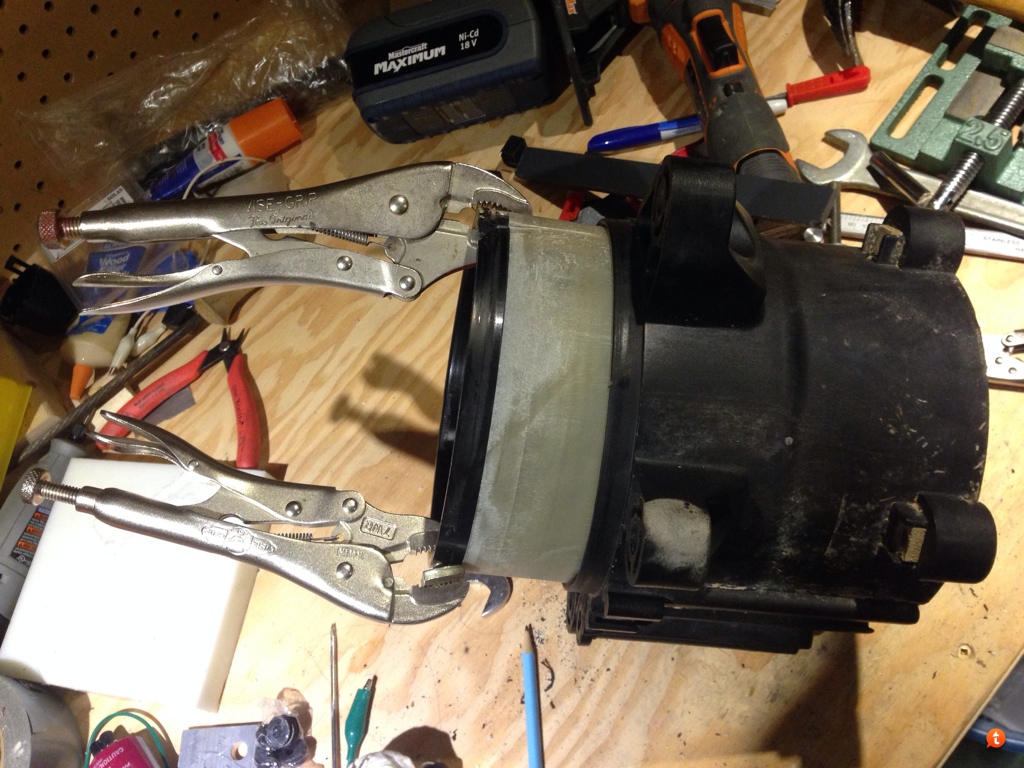

Freeze did the trick. The wear ring just slide in to the position. It was very tight before the freezing.

And I put the impeller temporarily back. It is pretty well centred and I can rotate it with a little friction between the impeller blade and the wear ring.

Sent from my iPhone using Tapatalk

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 340

- Replies

- 7

- Views

- 408

- Replies

- 7

- Views

- 854