Bonmotwang

Well-Known Member

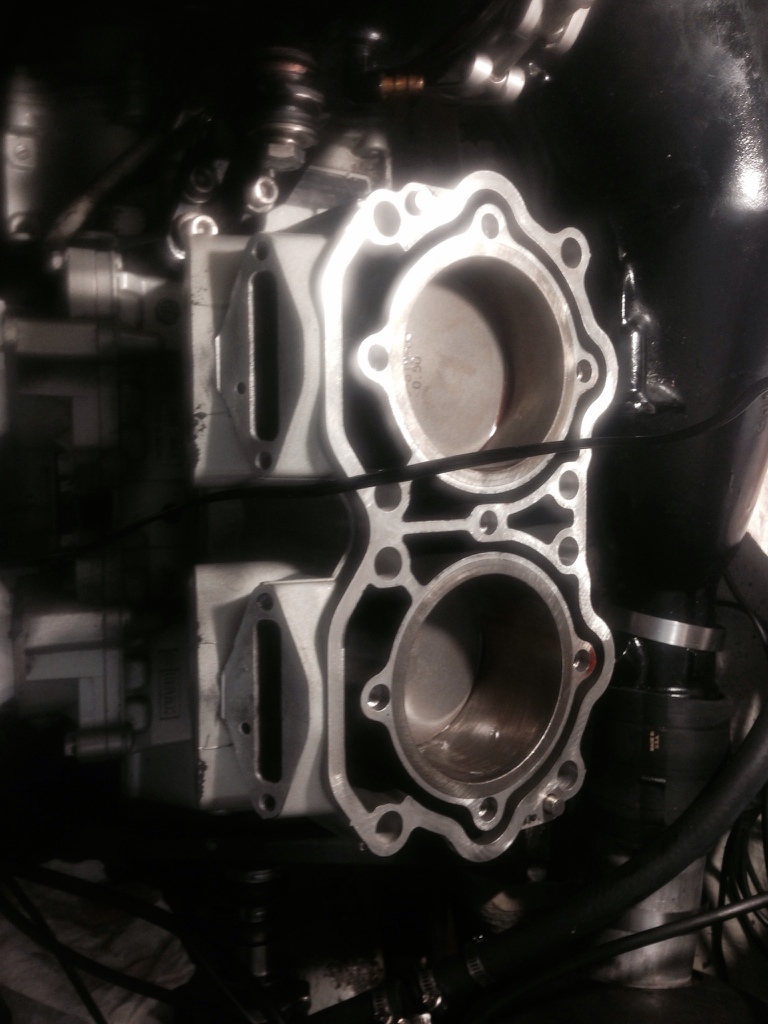

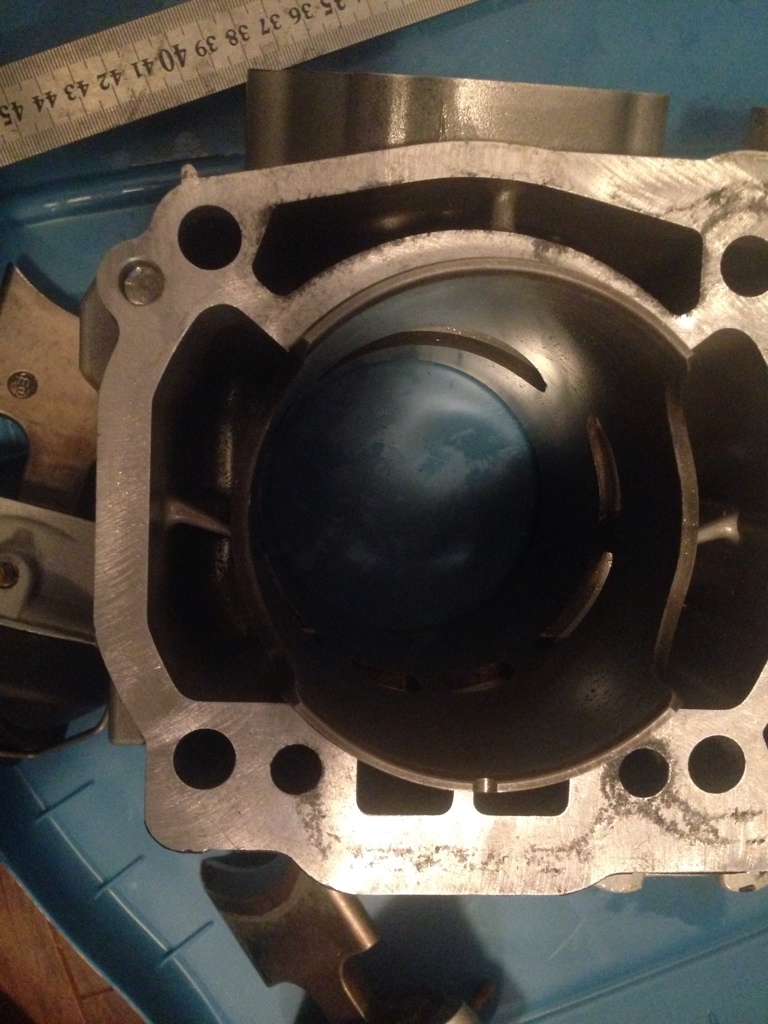

Base locating pins are in the crankcase. Top locating pins are in the cylinder.

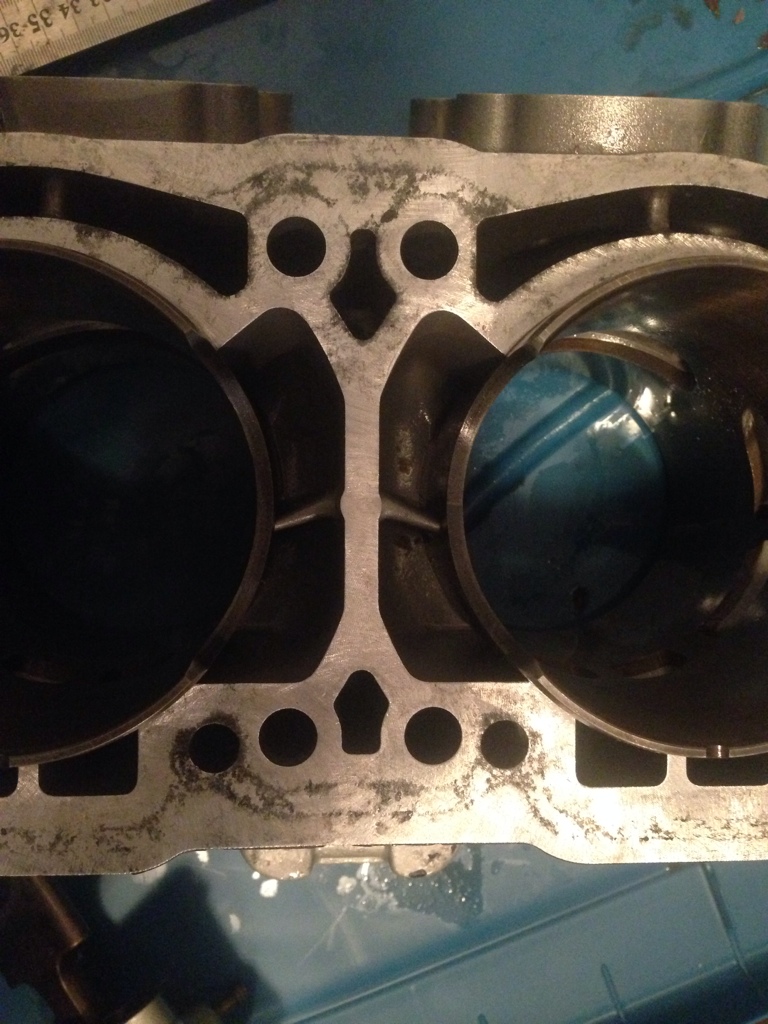

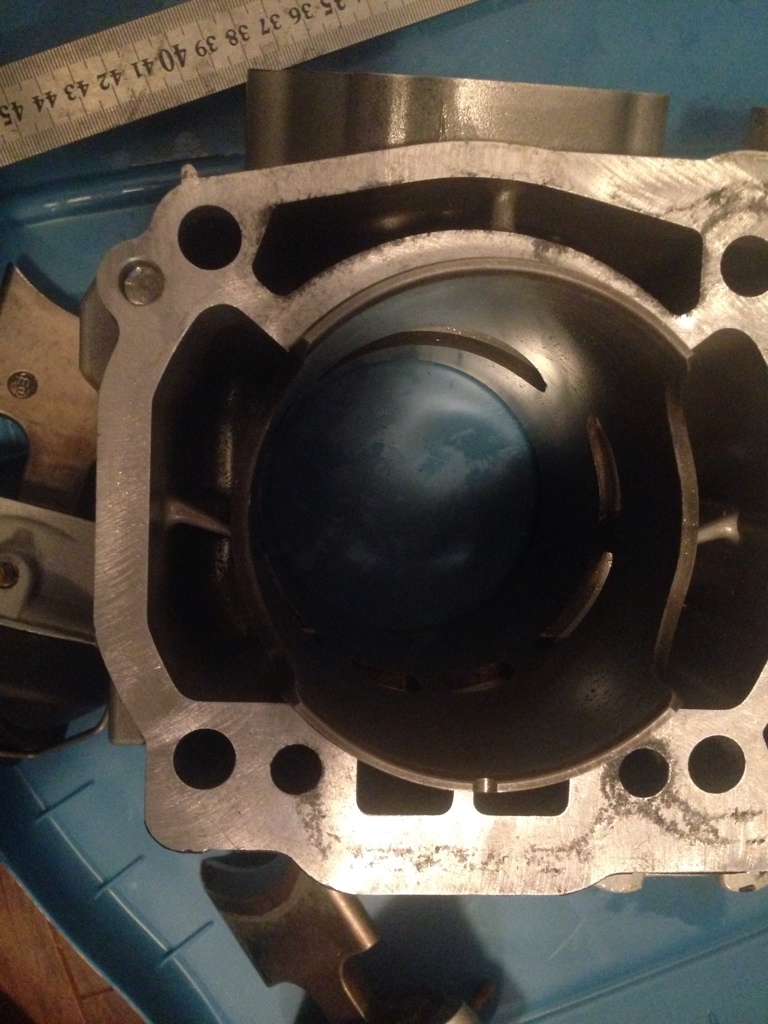

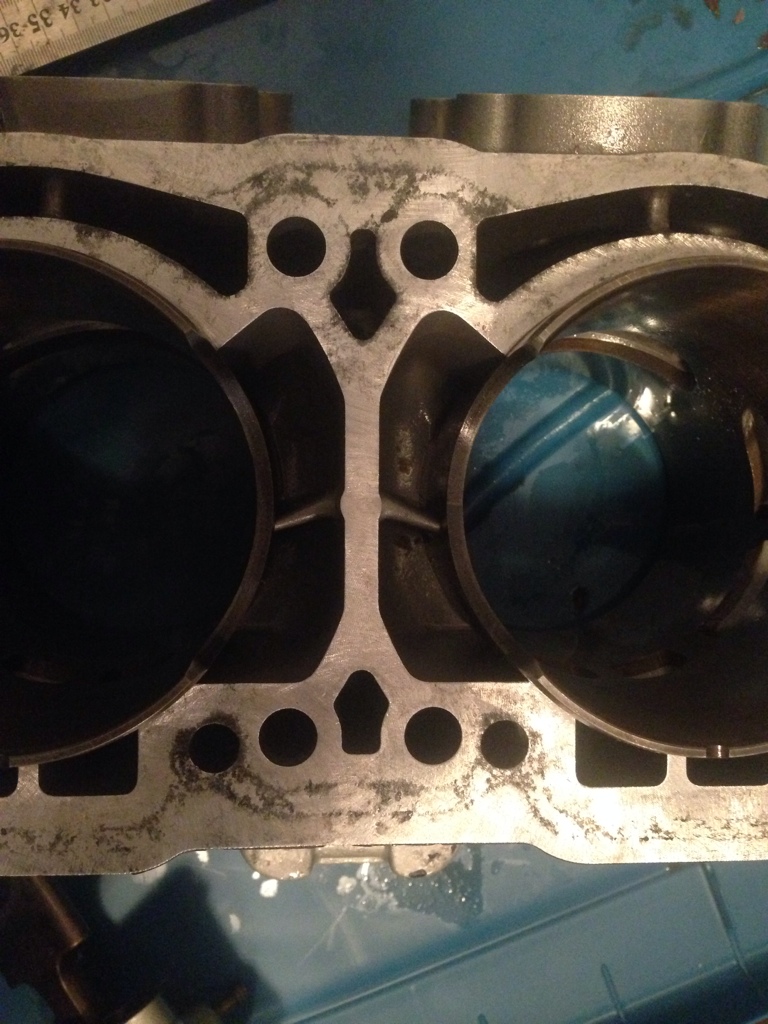

Looked at it again. Actually it is good. I moved a level around on the surface. The overall surface is flat.

I will try dry install.

Edit: added photos

Looked at it again. Actually it is good. I moved a level around on the surface. The overall surface is flat.

I will try dry install.

Edit: added photos

Last edited by a moderator: