Sportster-2001-951C-Stock

Well-Known Member

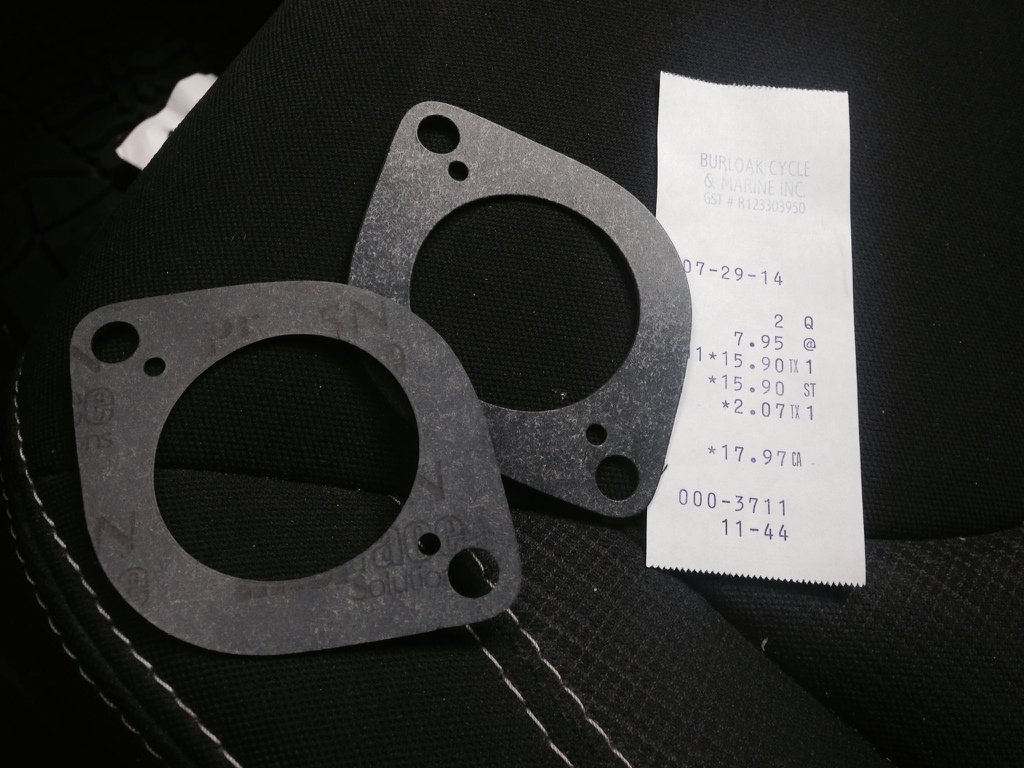

You should use new carb base gaskets if possible!

You should use new carb base gaskets if possible!

There is no fuel pump on PTO carb. So you only need the o-ring type gasket.

"If I turn the piston 90 degree, it will go in."

This must be the special Amsoil bore clearance? Although, this doesn't sound good to me b/c both piston and cylinder should be round?

I think sometimes the machinist is aggressive with honing in the cylinder top where the rings are traveling and not so much in the bottom. I guess this could make the bottom tighter. The problem with very aggressive "honing-to-fit" is the bore becomes out of round.

But, I'm not sure if the piston sleeve rod reliefs are causing confusion about which is out of round (piston or bore), my bet is the piston is round but the bore is oval.

And, I think your machinist should also properly chamfer the ports and clean the bore for you too.

I doubt he will do the port filing and bath. But I will ask. Really if he can make it "round" I will feel lucky.

I agree with you on the aggressive part. The bore bar went too fast and pushed out the sleeve bottom "clamshell". So bore bar couldn't take out enough material, which caused the tightness after bore bar got removed.

Sent from my iPhone using Tapatalk

Picked up the cylinder. He just re-honed the bottom part and tried fit. It is Still in my truck. I will double check tonight. But is it possible to take away 0.1mm (0.004") steel by honing??

Sent from my iPhone using Tapatalk

Easily (and quickly) depending on the hone and abrasive used although even a finish hone will take 0.1mm in a matter of less than 2 minutes for your bore size.

I wasn't thrilled to see your issue, he shouldn't have let that out the door like that under any circumstances.

When checking the ring end gap, slide the ring by pushing it with the piston crown to several locations and see if the diameter changes by measuring ring end gap. Also make sure there are no gaps between the cylinder wall and the ring!

http://twostrokemotocross.com/2012/10/wiseco-2-stroke-tech-tip-piston-ring-gap/

Motoseal is a really good product, I use it in some air cooled motor applications to eliminate the base gasket between the case and cylinder to maximize the squish and compression. You only need a very light film of it to do the job and it's a pretty thin wet product to work with and makes a mess if you try to apply to much of it.

Hey water lover, what is the white anchor thingy in your avatar?

Those are sand point anchors, much better to use on sandbars and beaches in shallow waters especially if there are many boats being parked side by side. You make them with a 5 foot length of 1 1/2" pvc pipe with a T glued to the top of it and a sharp angle cut into the bottom. I cut 16" lengths of 3/4" pvc for handles to insert into the T to help drive / rotate them down into the sand. They go in very easy and do an amazing job of holding the boat and fit in the floor locker no problem.

View attachment 26991 View attachment 26992View attachment 26993

Not bad, I might try making one of those. Not sure how it will work in our sand over clay-bed soil though, we use mostly those cork-screw dog ties in the shallow areas.

Alright I think I'll give that idea a shot, thanks!

You should use new carb base gaskets if possible!