Bonmotwang

Well-Known Member

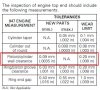

From Full Bores tech tips:

When installing WSM rings if there is a polished edge, it is installed in the top ring groove.

On Sea Doo 947/951 the rings only go on one way, if they don't compress in the groove flip them over. Small letters near end gap face up.

Thanks!

Sent from my iPhone using Tapatalk