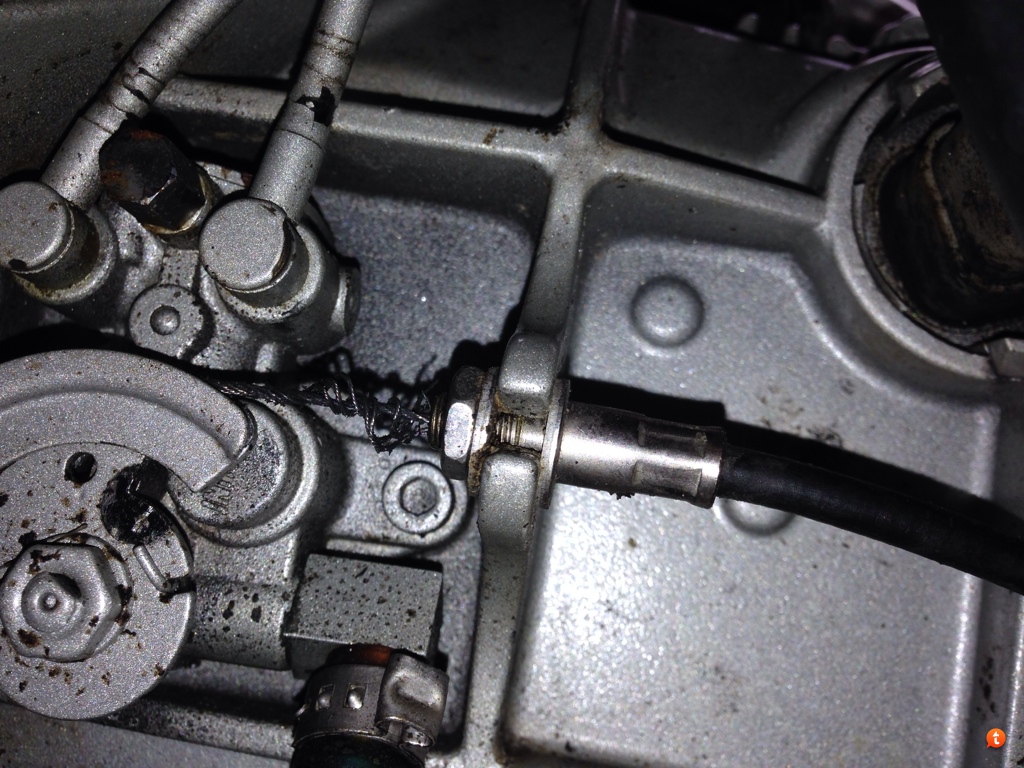

I attached two photos together to analyze what happened.

View attachment 25013

Is it possible I was push the throttle too hard when I "prime" the fuel before start the engine?

It looks like if I can take off the cable and bring it out to a working space, I can connect a new short cable to the end with a ferrule or some kind of crimp tool.

But the big "IF" is: if I can adjust the sheath shorter by minimum 2".

Yeah, tough luck on the cable, maybe it was already damaged b/c you confirmed it was adjusted correctly. At WOT position the carb butterflies should just reach their open stops. It must be correct if you can adjust the idle speed.

I think the only possibility of cable repair is to trim the outer sheath by the same amount as the inner wire, otherwise you cannot adjust for the correct position. Maybe this can be done at the plastic adjustment ferrule.

But I'm not sure if it can still reach, maybe it can.

My motor does jump around some, but the idle speed is higher. No wonder the exhaust bracket is broken, eh? Check the engine mounts to make sure they're not torn or broken lose, you should not be able to rock the motor from it's position by pushing on it.

The low speed idle mixture screws are on top of the carbs, near the mounting flange on the stern side of the carbs. Could be they aren't set to 1.5 turns out from lightly closed finger tight. More in is leaner and more out is richer low speed mixture. It takes patience to reach them, it's a tight space. The engine should not race higher and higher out of water, mine doesn't. Any air leak can cause a lean mixture too, like if a gasket is missing, so look for lose mounting bolts or some air leaks on the vacuum side of the butterflies.

If the stop button can't stop it, this is thermal runaway of the spark plug electrode heat (dieseling glow plug) and the choke can stop it in that case. I think if you adjusted 1300 in water the trailer speed should not exceed 3000 RPM, my expectation.