rjcress

Active Member

thanks.Awesome thread man, that challenger is turning out great!

Have you posted pics of yours yet?

thanks.Awesome thread man, that challenger is turning out great!

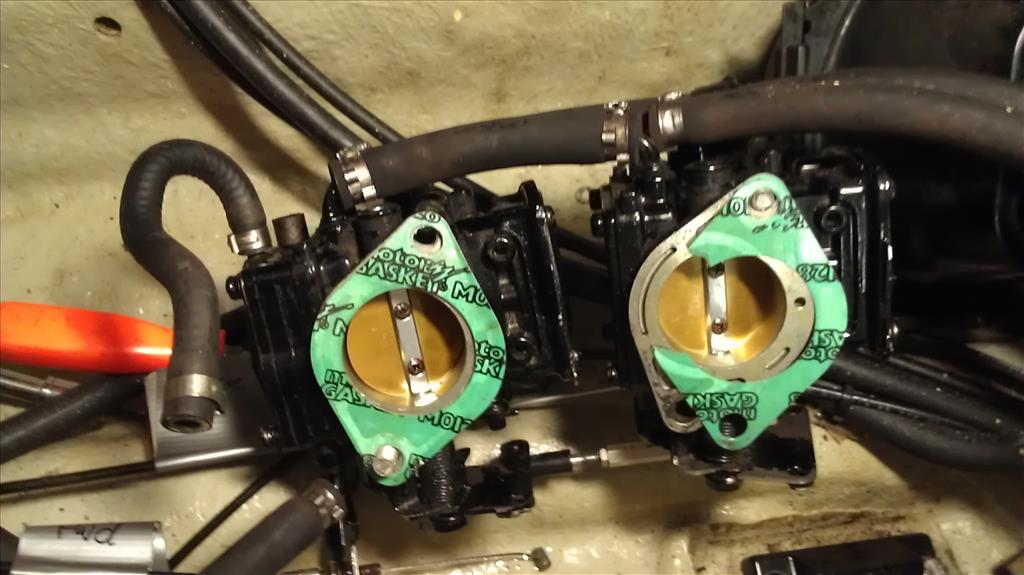

May have found the source of my fuel delivery issues... PTO carb gasket was not centered and has a one inch section missing.

looks like the gasket was only on one of the studs.wow, how did that happen? did the engine get hurt?

looks like the gasket was only on one of the studs.

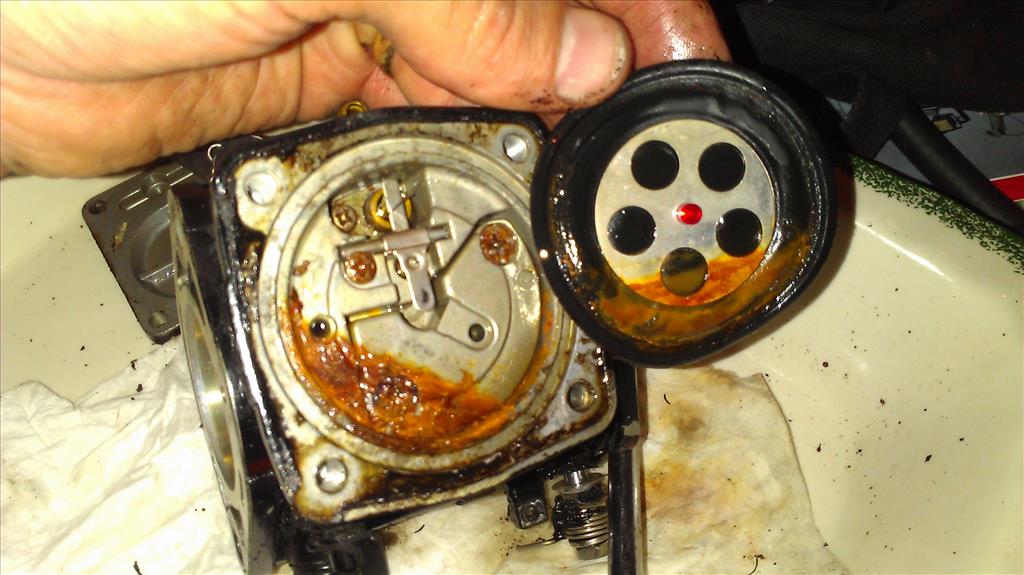

tore the carbs down and both were dirty and had rust from water sitting in them

clean now though

almost done with 2nd one. will post pics and reinstall later this week

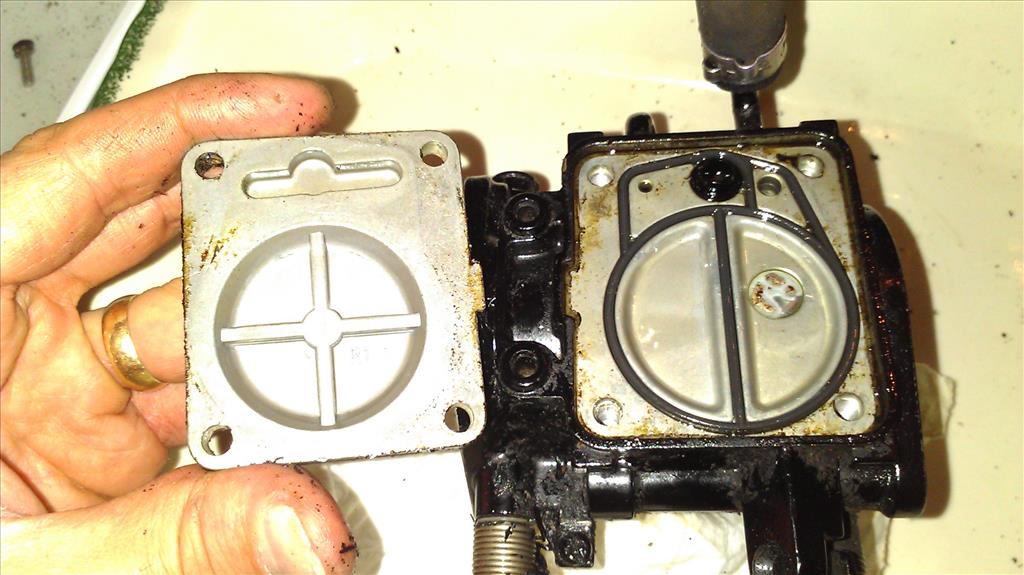

From the imprint on the torn gasket, I can see that I installed it improperly.:facepalm: I only had one side of the gasket on a bolt. the other one missed, and the gasket pivoted down 10 degrees, or so. This put part of the gasket in the carb throat where it looks like the suction tore off part of the gasket. I embarrassed that I didn't notice this before running the engine and didn't see the gasket any time that I looked in the carbs, so I'm guessing that it was sucked in the first time I fired the engine. I've probably got almost 2 hours on the engine now. Hoping that the ingested gasket piece blew through without any issue. I haven't seen any signs that anything is blocked in the exhaust, but haven't torn it down to check. This could also explain some/part of the low speed issues I've been having. Too many potential causes for that right now.:willy_nilly:wow, how did that happen? anyway, you are using the thicker OEM gaskets yes?

... As for the condition of the carbs, WOW. Am I understanding correctly that it actually RAN like that? Holy cow, those look pretty bad. I'm surprised you got anything through the jets at all what with all that rust everywhere. ... I hope you get your boat back online soon so we can compare data points. I'm still chasing gremlins on my Challenger.

They aren't paper thin, but I don't have any others to compare them to.are those gaskets thin? I would recommend OEM thick seadoo gaskets. I have learned that the thin jetski gaskets wick.

Yeah, I'm thinking I'll get the OSDparts kit, as it is mikuni parts, plus a couple of parts that aren't in the standard kits, but are often needed.Since you have them apart, I would invest in new needles and seats and a complete kit. I`ve only heard to use Mikuni kits, have no experience with anything else.

Yep. My sig is what it is for a reason. :thumbsup:now, if I want to poke at ya, your signature comes to mind! hahahahahaha

I would really rethink about moving forward with this project until you repair the electrical box, that is a dangerous hazard...

good luck...

Don't forget to check the spin on filter after your first few hours of operation. You might start pulling stuff up from the tank if it has been sitting for a long time in the past. My filter got all sorts of clogged when I first started using the boat after 1+ years of sitting.

If you need a wiring diagram on the fuse block my manual has one. By the way the Challenger is looking good:thumbsup:

I would go ahead and order needles and seats to go with the carb kits. Ask me how I know!!:facepalm:

Get a new fuel selector valve instead of trying to clean the old one. It is not worth cleaning. Ask me how I know!!:facepalm:

I ordered the kit from OSDParts.com because it included the needles and seats.

On the fuel selector, I didn't see any difference in going from "on" to "res", which I gather is the most common tell-tale sign. I also didn't get any gunk out of it. However, I've never opened one up. I only saw one screw on mine, and I didn't take that screw out. I'll see if it comes apart to do a more thorough cleaning, as the carb cleaner and compressed air didn't produce any gunk. I wonder if a pipe cleaner would work? I'll grab one out of the kid's craft cabinet and see if it dissolves in gas... if not, I'll try it.

Anyhow, I know that I just rambled about cleaning it, when you said it isn't worth the trouble. You are probably right. I just don't have time to get a new one before heading to the lake tomorrow evening... so taking a shot at cleaning the existing one is my best option. I don't have a SD dealer close by at home, but there is one at the lake. If it appears to be giving me problems I can see if they have one Saturday.

There is a rubber grommet inside the selector valve. It gets old and worn then somehow gets out of position and won't let the fuel flow unrestricted, but when you blow on the valve it feels like everything is good...until you blow on a new one and feel the difference.