Well. Last night I actually got all 3 things on my list for this week done. I think I was almost as surprised as my wife when she came to the garage at 3:45 am and said "why are you still up?".

-Depth/fish finder installed

-LEDs in engine bay, passenger area and transom installed

-Voltage readings available

I knew it was late, but not THAT late. I had a series of wiring challenges that really drug the LED wiring out WAY longer than it should have.

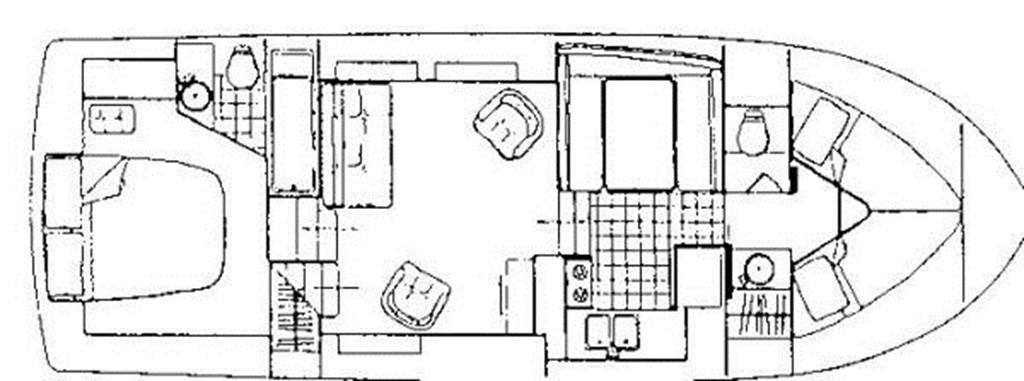

If these work well the next few days, then I'll sit down and design a better wiring setup. Everything is sufficiently fused, so I'll be looking at a bus bar like the BLUE SEA SYSTEMS DualBus Plus, or maybe something like the BLUE SEA SYSTEMS ST Blade Fuse Block since some of my current fuses are blade and some are the old glass tube fuses. I'd like to have all blades so I have less spares to carry.

It is a shame that a replacement factory SD fuse block isn't available, as that would be easier.

Anyhow, I didn't actually install the voltage gauge. When I got the fish finder hooked up and turned it on I immediately saw that it displays voltage. So the voltage gauge was not needed at this point.

No pics yet of the wiring, as some of what I did is ugly.

The fish finder is mounded to the driver's cup holder via 4 bolts that pass through the cup holder. So, the only holes drilled were in the $2.50 cup holder. I expect that when budget permits I'll upgrade to the 2" depth gauge instead of the MASSIVE fish finder, so this temporary mount is the best option I could think of.

LEDs:

Engine bay:

Engine vent. I only had one of these little Amber LEDs... may have to order one for the other side:

Transom. Really hard to get a good pic of the lights on in my lit garage. VERY anxious to see how they look at night in the water and if the "waterproof" 3M tape that is holding them on is really waterproof:

Under helm light and new speaker:

New radio and cover: