Jetskigoodies

Well-Known Member

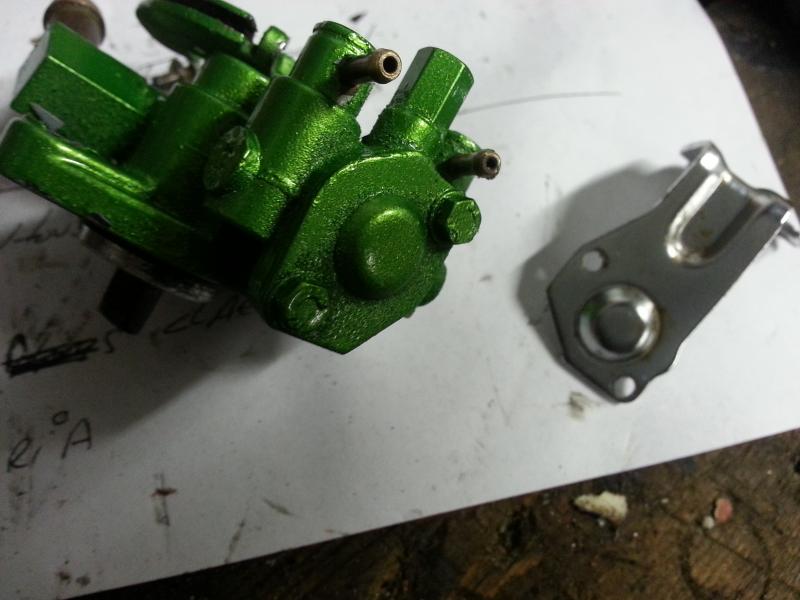

The motor is back from getting painted and will be going in soon

Yes that's correct, also tell him to test before he runs it. To test: place the valves in there slots without the billows and rotate the engine over and watch the valves, should they even move in the slightest more needs to be shaved.Ok the owner is shaving the raves. I told him to take off .25 mm. His bore is .5 over. Just making sure this is correct. Anyone ever shave down their raves? We always have full bore do it so I never really looked into it. The bore .5 is taken off the diameter. Since the rave is on one side of the cylinder wall we would need to shave enough clearance for the radius. The stock clearance is enough to even bore the cylinder .25 over and not need a trim.

Well that's one way to do it lol