Jetskigoodies

Well-Known Member

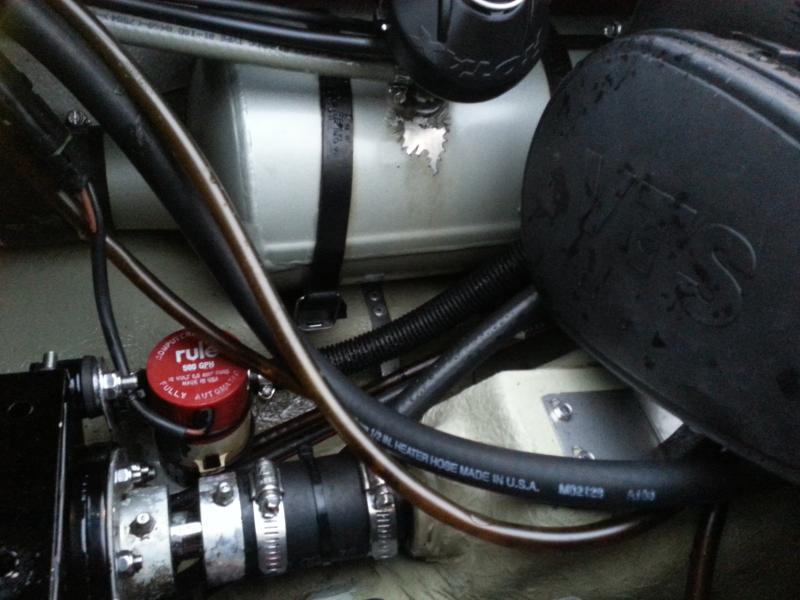

Need a couple parts for this, sooo [MENTION=29781]Spimothy Leary[/MENTION] [MENTION=51824]Matt Braley[/MENTION] and [MENTION=41828]Minnetonka4me[/MENTION] I need an oil cable and the throttle cable bracket for the mag side carb. Figured I would ask you fellas before I look on ebay.