-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dr Honda's Islandia Project. (Engine rebuild, and other stuff)

- Thread starter Dr Honda

- Start date

- Status

- Not open for further replies.

Dr Honda

Well-Known Member

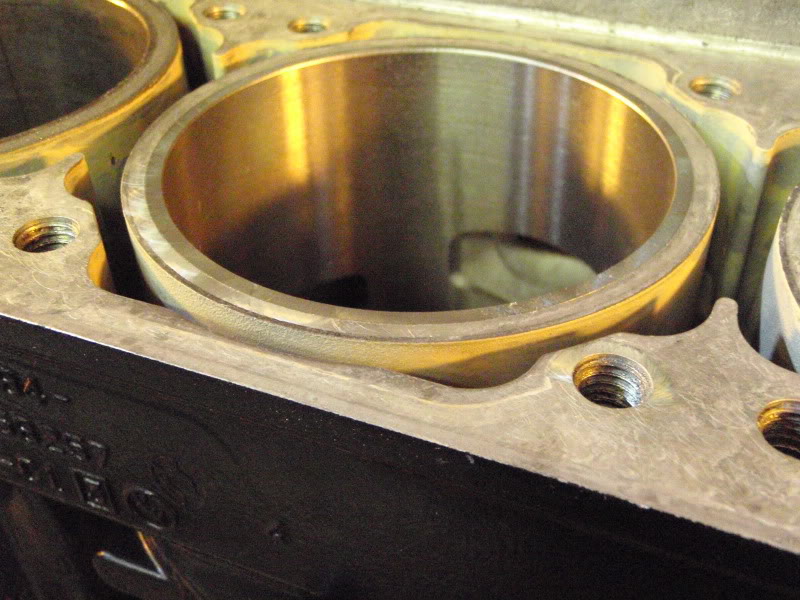

Tonight's lesson is entitled "Cooking for the home mechanic". Or... how to install an engine sleeve.

Set your oven to about 450, and let it pre-heat well. While that's happening... clean your block of any dirt or oil. Once ready, put it in the oven for about 45 minutes. When ready... the engine will be very hot, so use some welding, or work gloves. The engine block bore is actually about 0.004" smaller that the OD of the new sleeve. But... with a little Physics lesson... we know metal expands when hot. At 450 degrees, we actually achive a ID of the block bore of about 0.006" bigger than the sleeve. When you pull the block from the oven... you have about 5 to 10 seconds to get the sleeve in, and in position before the block will shrink down, and grab the sleeve.

This method can be used for the regular Rotax jugs too. But they are easy since they are open on both sides. As you can see... the Merc block is "Blind" and doesn't have an open bottom.

Tomorrows lesson will be how to bore and hone a new cyl.

Last bit of advice... do this when the wife isn't home... or... the lesson will be... "how to start the divorce proceedings. :lols:

Set your oven to about 450, and let it pre-heat well. While that's happening... clean your block of any dirt or oil. Once ready, put it in the oven for about 45 minutes. When ready... the engine will be very hot, so use some welding, or work gloves. The engine block bore is actually about 0.004" smaller that the OD of the new sleeve. But... with a little Physics lesson... we know metal expands when hot. At 450 degrees, we actually achive a ID of the block bore of about 0.006" bigger than the sleeve. When you pull the block from the oven... you have about 5 to 10 seconds to get the sleeve in, and in position before the block will shrink down, and grab the sleeve.

This method can be used for the regular Rotax jugs too. But they are easy since they are open on both sides. As you can see... the Merc block is "Blind" and doesn't have an open bottom.

Tomorrows lesson will be how to bore and hone a new cyl.

Last bit of advice... do this when the wife isn't home... or... the lesson will be... "how to start the divorce proceedings. :lols:

I noticed the cupcakes in the background. Did you bake those too?

Kinda reminds me of what happened to me a few years ago. Besides SeaDoo's I also like trains, I am the former road foreman of engines for a local railroad operation. I was working on a MRS1 locomotive and brought home some air brake parts to work on. Since my wife wasn't home I decided to use the dishwasher for a parts washer. All went well until the wife got home, busted! However ten years later we're still married.

Lou

Kinda reminds me of what happened to me a few years ago. Besides SeaDoo's I also like trains, I am the former road foreman of engines for a local railroad operation. I was working on a MRS1 locomotive and brought home some air brake parts to work on. Since my wife wasn't home I decided to use the dishwasher for a parts washer. All went well until the wife got home, busted! However ten years later we're still married.

Lou

El Toro 33809

Well-Known Member

Love the muffins in the background of the second photo!!!

Lookin tasty Doc. You might wanna mod that oven rack, the block looks a little heavy for it.

Dr Honda

Well-Known Member

The wife was baking the muffins when I told her what I needed to do. She wasn't happy with it... but she wants the boat to run as bad as I do.

RFoster: yes... that rack was questionable, but I didn't want to set it on the bottom of the stove. I haven't weighed the block... but it's probably close to 40 Lbs. But at least my kitchen workbench is strong. (lol) When I moved into that house, the kitchen needed some love, so I did a remodel. That island counter top is 3/4" MDF then 5/8" hardy backer... and topped with 5/8" granite. So... it could have taken the heat directly... but to save any nicks and chips.... I put down an old towel, and an extra granite tile.

Oh... and FYI... if you go to your local home store... a couple 12" granite tiles are great around the garage. You can put hot things on them... but you can also use it as a surfacing plate. Just put a piece of wet/dry sand paper on it, and then slide your part back and forth to get a nice flat flange.

RFoster: yes... that rack was questionable, but I didn't want to set it on the bottom of the stove. I haven't weighed the block... but it's probably close to 40 Lbs. But at least my kitchen workbench is strong. (lol) When I moved into that house, the kitchen needed some love, so I did a remodel. That island counter top is 3/4" MDF then 5/8" hardy backer... and topped with 5/8" granite. So... it could have taken the heat directly... but to save any nicks and chips.... I put down an old towel, and an extra granite tile.

Oh... and FYI... if you go to your local home store... a couple 12" granite tiles are great around the garage. You can put hot things on them... but you can also use it as a surfacing plate. Just put a piece of wet/dry sand paper on it, and then slide your part back and forth to get a nice flat flange.

jhjesse

Well-Known Member

Cool idea. On my job we are always having to "shrink" bushings/sleeves into mating parts. We sometimes use a "rosebud" torch and temp guns to achieve the correct temperature, but the best fun is to use liquid nitrogen and a cryo bucket.

When the guys are through shrinking bushings and there is some left over nitrogen in the cryo bucket, I'll see them digging into their lunch buckets. They freeze apples oranges etc. and then toss the frozen fruit into the air and watch it hit the ground and shatter like glass.

What reminded me of this was one of my guys froze a cupcake...you should've seen this thing shatter. It was hilarious!

When the guys are through shrinking bushings and there is some left over nitrogen in the cryo bucket, I'll see them digging into their lunch buckets. They freeze apples oranges etc. and then toss the frozen fruit into the air and watch it hit the ground and shatter like glass.

What reminded me of this was one of my guys froze a cupcake...you should've seen this thing shatter. It was hilarious!

Dr Honda

Well-Known Member

I was talking with another machinist buddy... telling him what I was up to... and he suggested doing the cryo method on the sleeve. (to avoid the potential wife issues) BUT... the extreme cold can actually harden the iron alloy sleeve. THEN... you have to worry about it cracking during the break-in. (and until it anneals again)

Also... the oven works best for an engine block or jug. That way you get a good heat soak, and it's an even expansion. If you heat it with a torch... you may not expand it even. THEN... the sleeve may crack, or worse... get stuck half way down. (that's $100 mistake)

Also... the oven works best for an engine block or jug. That way you get a good heat soak, and it's an even expansion. If you heat it with a torch... you may not expand it even. THEN... the sleeve may crack, or worse... get stuck half way down. (that's $100 mistake)

Last edited by a moderator:

El Toro 33809

Well-Known Member

Back in the day when I raced motocross, we did the oven trick when replacing crank bearings. Case in the oven and the bearings in the freezer......

Dr Honda

Well-Known Member

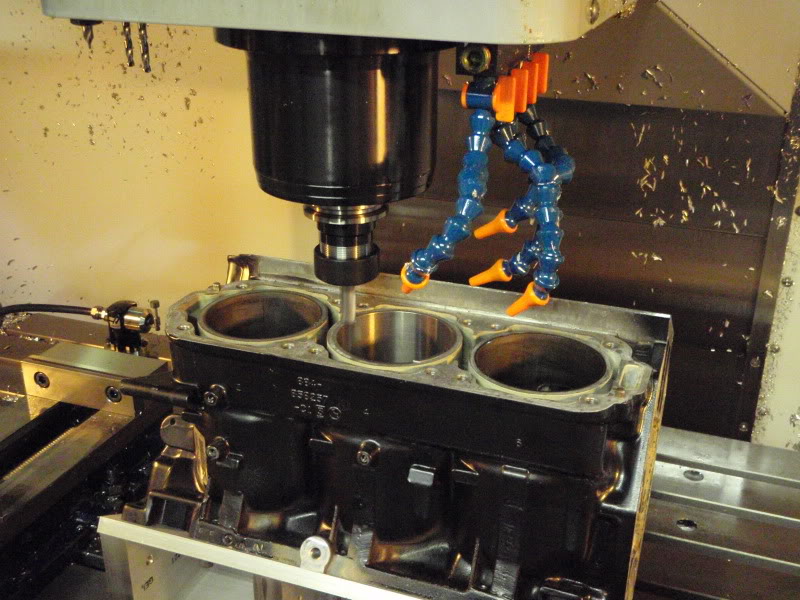

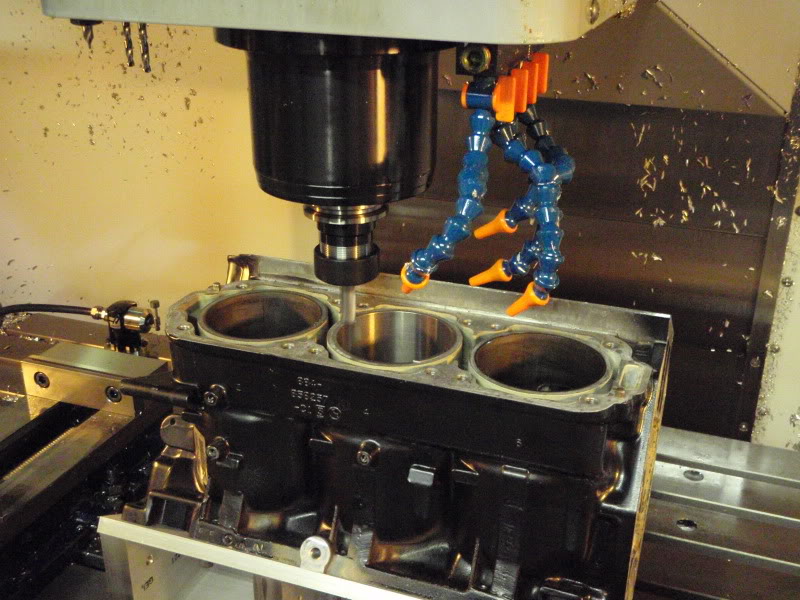

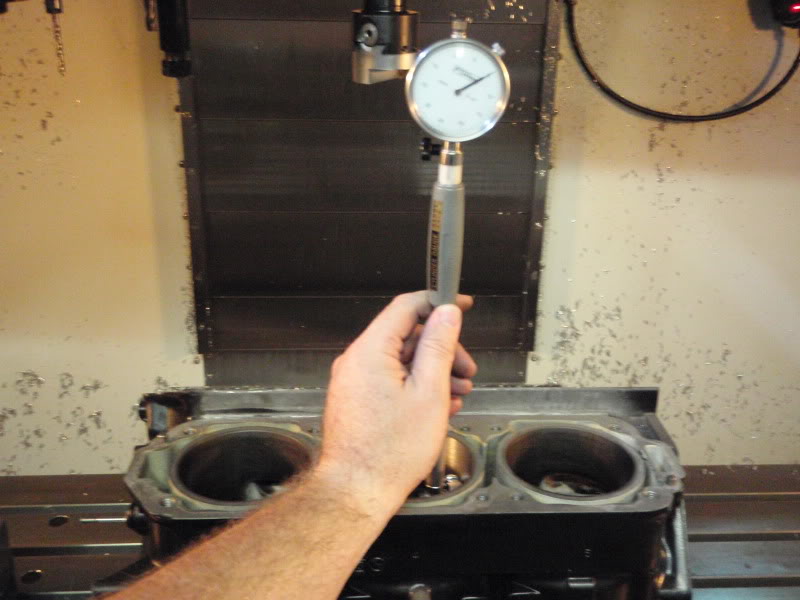

OK... The engine went back into the mill to be decked, bored, and honed. For some reason, I couldn't get a clean cut with my Boring head... so I left a lot of extra material in the cyl. This makes for a very nice cyl... but it takes a VERY long time to hone it to size.

Pic 1: Cutting the extra sleeve. (decking)

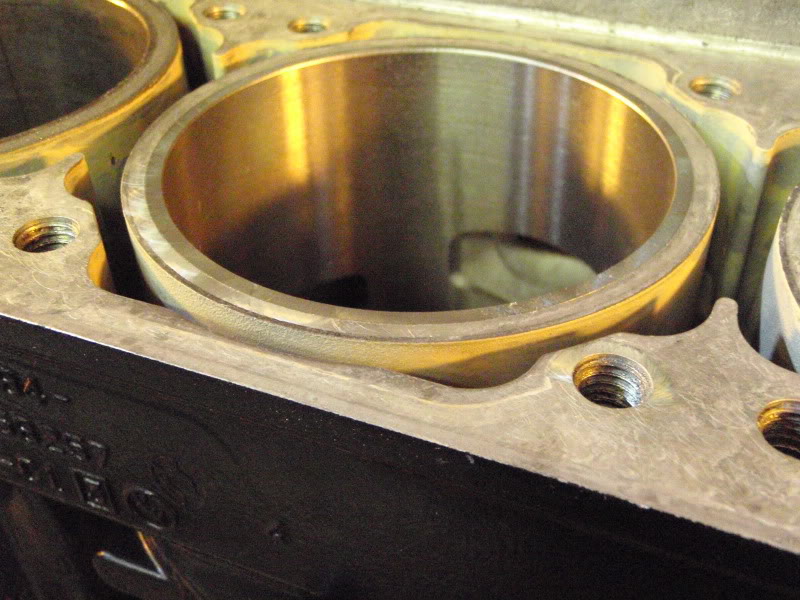

pic 2: Looks good to me

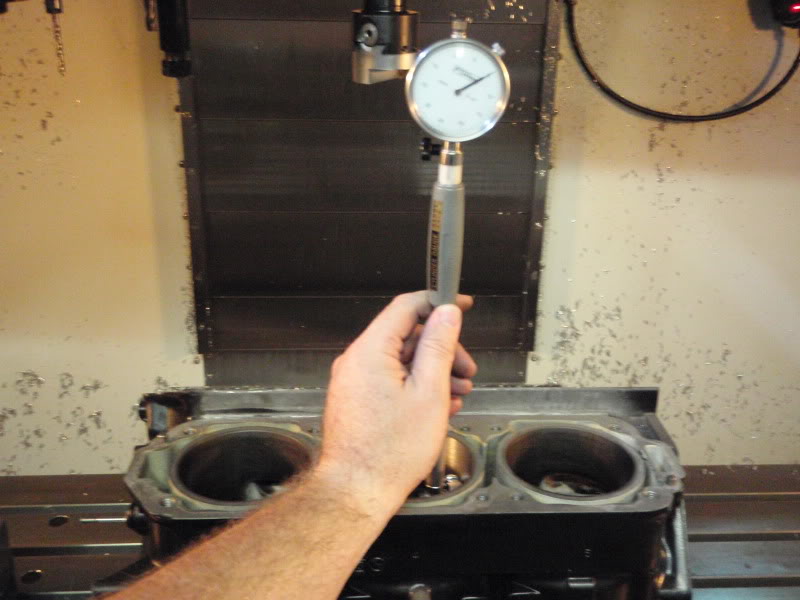

Pic 3: Slow going with the hone. Have about 0.005" more to go.....

Pic 1: Cutting the extra sleeve. (decking)

pic 2: Looks good to me

Pic 3: Slow going with the hone. Have about 0.005" more to go.....

Dr Honda

Well-Known Member

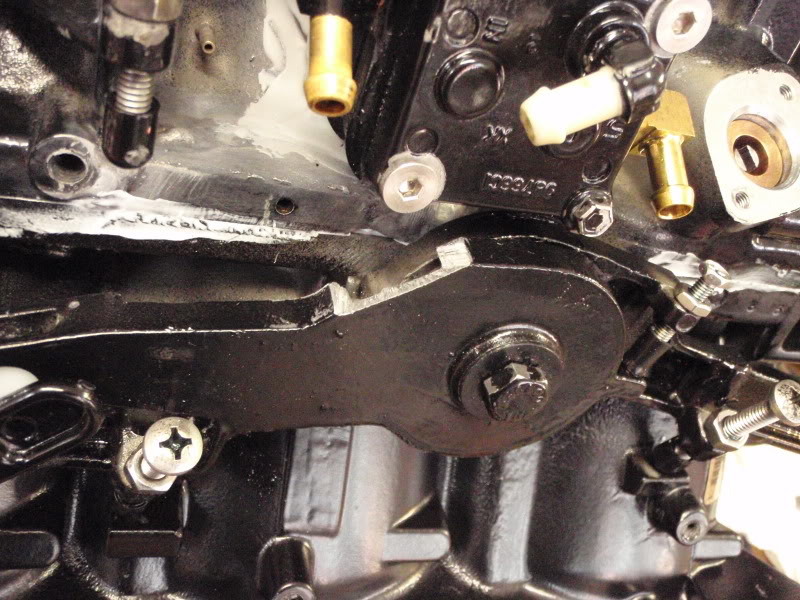

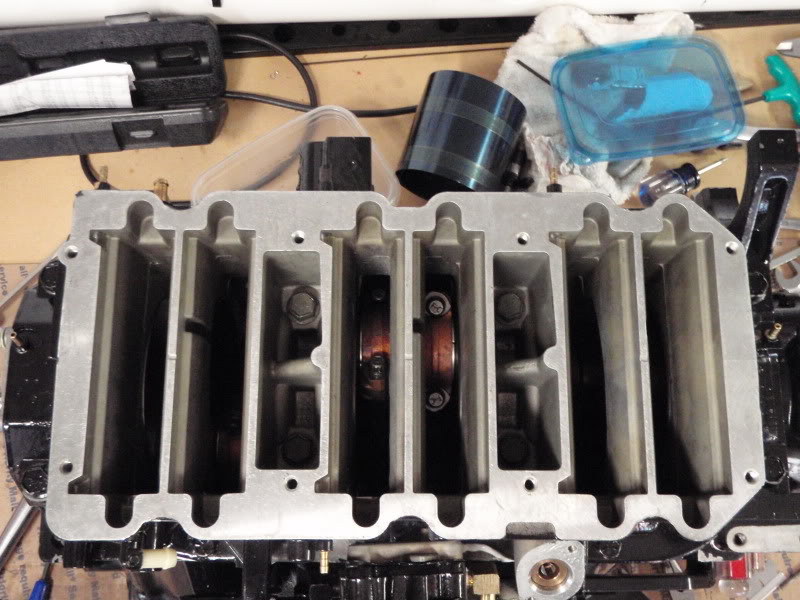

Played hooky today. SO... I did a finish hone on the new cyl... and de-glazed the other's. Then... I started to put it together.

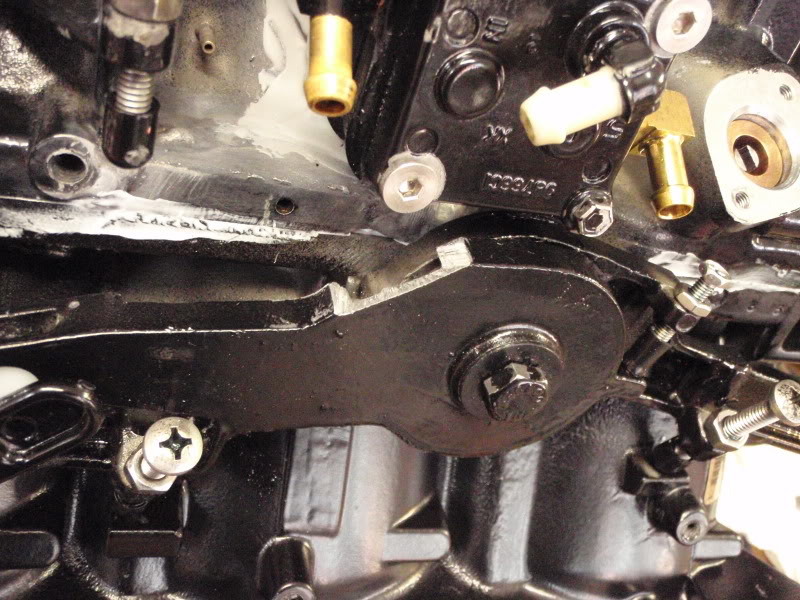

Oh... and for the guys who actually have been reading my posts... well... when I welded the fuel pump bracket back onto the engine block... I made it straight. (originally, it was mounted a few degrees off) The first problem was that the outlet fuel fitting was going to hit the oil pump... but that was fixed with a 90 degree fitting. BUT... once I put the throttle arm back on the engine... I found that it would hit the pump. (UGHHH) After looking at it for a few minutes... I realized the part that was hitting was superfluous. So... I cut it off. (LOL) Seems to work now. If I need to... I'll weld over the opening to strengthen it.

On a bright note... the connecting rod doesn't hit any of the internal welds.

Last thing... I didn't use the Loctite 518 that they said to use. (I was never a fan of it) So... I used ThreeBond 1211. Since I had to weld up the back case, and machine a section of the block... It would be in my best interest to use something that is known to fill small gaps. (that's the white stuff coming out from between the cases)

Oh... and for the guys who actually have been reading my posts... well... when I welded the fuel pump bracket back onto the engine block... I made it straight. (originally, it was mounted a few degrees off) The first problem was that the outlet fuel fitting was going to hit the oil pump... but that was fixed with a 90 degree fitting. BUT... once I put the throttle arm back on the engine... I found that it would hit the pump. (UGHHH) After looking at it for a few minutes... I realized the part that was hitting was superfluous. So... I cut it off. (LOL) Seems to work now. If I need to... I'll weld over the opening to strengthen it.

On a bright note... the connecting rod doesn't hit any of the internal welds.

Last thing... I didn't use the Loctite 518 that they said to use. (I was never a fan of it) So... I used ThreeBond 1211. Since I had to weld up the back case, and machine a section of the block... It would be in my best interest to use something that is known to fill small gaps. (that's the white stuff coming out from between the cases)

Last edited by a moderator:

Very impressive work. Lookin good. Wish i lived close enough to just stop by and check it out sometime.

Dr Honda

Well-Known Member

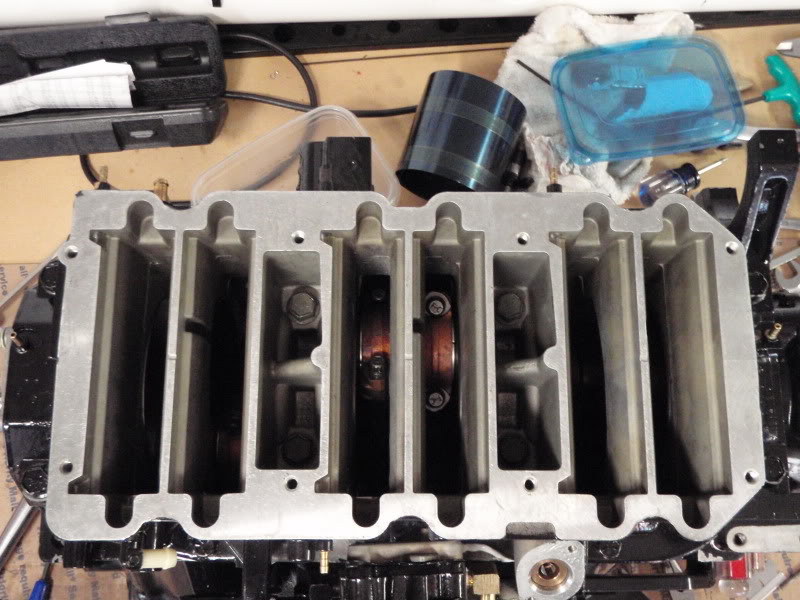

Working my butt off today. It's friggin' hot in Pitt right now. (90 with high humidity)

Anyway... I'm stopping to eat some lunch, and thought I'd post a pic. Because It's hot, and I'm slowing down... the plan is to finish the engine today, and do the install tomorrow morning !!!!!!!!!

TIP OF THE DAY: OK... sometimes the way to do something is obvious. And, sometimes it isn't .

Today, I tried to install the power-head onto the "Expansion Chamber Plate" by myself. The way I was doing it was that the plate was sitting flat on the floor, and I put the gasket on it. (there are a couple pins to hold it) Well, the Power head weighs about 200 Lbs, and I was lifting it, and trying to line it up, but every time I would get close... the gasket would move. So, after sitting and thinking... I realized the with the "Carbs" off... I can set the engine flat on the floor, on the intake... and then I could just hold the plate up to the engine. (it only weighs about 30 Lbs)

So if you're working on a Merc... just remember that.

FYI... the new yellow bleed system hose is tygon. It's fuel and oil safe.

Anyway... I'm stopping to eat some lunch, and thought I'd post a pic. Because It's hot, and I'm slowing down... the plan is to finish the engine today, and do the install tomorrow morning !!!!!!!!!

TIP OF THE DAY: OK... sometimes the way to do something is obvious. And, sometimes it isn't .

Today, I tried to install the power-head onto the "Expansion Chamber Plate" by myself. The way I was doing it was that the plate was sitting flat on the floor, and I put the gasket on it. (there are a couple pins to hold it) Well, the Power head weighs about 200 Lbs, and I was lifting it, and trying to line it up, but every time I would get close... the gasket would move. So, after sitting and thinking... I realized the with the "Carbs" off... I can set the engine flat on the floor, on the intake... and then I could just hold the plate up to the engine. (it only weighs about 30 Lbs)

So if you're working on a Merc... just remember that.

FYI... the new yellow bleed system hose is tygon. It's fuel and oil safe.

Last edited by a moderator:

Nice going so far. You won't be too far off your ETA of Aug 4th.

You P/U the boat at end of May?????....lots of work done in about 2 months or so.

I bet your family can't wait to get on it.

You P/U the boat at end of May?????....lots of work done in about 2 months or so.

I bet your family can't wait to get on it.

Dr Honda

Well-Known Member

Nice going so far. You won't be too far off your ETA of Aug 4th.

You P/U the boat at end of May?????....lots of work done in about 2 months or so.

I bet your family can't wait to get on it.

Yep... my oldest wanted to go out today. I told her that I have a lot to do still.

Anyway.... Time for dinner................. And I have an engine! :thumbsup:

As long as something doesn't come up... I'll be doing the install tomorrow. But I will say this... I now know why they charge $2k to $3K to do an install on these. I basically spent a day with the build... and a day cleaning, and putting on all the stuff. (EFI, electronics, expansion chamber, etc)

Last edited by a moderator:

africlawed

New Member

DR Honda , i'm new to the forum and from canada , am really intrested in your rebuild , but i somehow missed where u bought the rebuid kit from, was it complete ? 6 pistons bearings ,ect pls help as now its my turn to rebuild a merc 240,,,from a speedster, thanx for a great post thus far,,,,claude

Tony, that thing is a MONSTER...close to 400 lbs or so????

What type of lift do you have?

I would have to assume that this is too heavy for the typical average mickey mouse mechanic to lift in his garage.

What type of lift do you have?

I would have to assume that this is too heavy for the typical average mickey mouse mechanic to lift in his garage.

Dr Honda

Well-Known Member

DR Honda , i'm new to the forum and from canada , am really intrested in your rebuild , but i somehow missed where u bought the rebuid kit from, was it complete ? 6 pistons bearings ,ect pls help as now its my turn to rebuild a merc 240,,,from a speedster, thanx for a great post thus far,,,,claude

I'm sure I said it somewhere.... but I got the kit from eBay. THe person's name was "Fasterthanmachone". The shop who the kit came from is Tri-State Marine. (A real shop) The kit looks like it's basically a re-badged WSM kit. It's good quality, and the price was right. Also, I had one of the main bearings that I didn't like... so... I called the shop, and they sent me a new one.

I recommend them.

Tony, that thing is a MONSTER...close to 400 lbs or so????

What type of lift do you have?

I would have to assume that this is too heavy for the typical average mickey mouse mechanic to lift in his garage.

I think it's about 300 Lbs fully dressed.

Yes... it's too heavy to lift out without a shop crane. Even if you get 2 guys... it's awkward, and if you drop it... you will mess up the boat. I'm using a regular shop crane (engine hoist) but I had to extend the main boom about 8" to reach into the Islandia. (it has a huge swim deck) I don't recommend doing that... but sometimes you have to do things you normally wouldn't do to make it work. There was another member who did the extension right. He added about 2' to the boom, and the the support legs.

Last edited by a moderator:

Guest_User

New Member

Very Impressive rehab! Great Job!:thumbsup::cheers:

africlawed

New Member

Thanx Doc, hope he ships to canada,u've been a great help,,,,claude:thumbsup:

Dr Honda

Well-Known Member

Well.......... around 2 O'clock... the rain let up... so I got out there... and installed that thing!!! It didn't start right away, but after a little digging... I found the feed hose was leaking a little, so it was sucking air. After I cut the hose clean, and got it clamped tight... she fired right up. :cheers:

I have a few Odd's-N-End's to take care of... but as soon as I can get a little free time... I'll give her a water test.

I have a few Odd's-N-End's to take care of... but as soon as I can get a little free time... I'll give her a water test.

Last edited by a moderator:

Racereddie

New Member

I have a few Odd's-N-End's to take care of... but as soon as I can get a little free time... I'll give her a water test.

Great job, I bet the anticipation is working its way on you and I bet you won't wait for some free time, but will make some here soon. Have a great time!

Eddie

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 300

- Replies

- 5

- Views

- 395

- Replies

- 2

- Views

- 362

- Replies

- 1

- Views

- 161