El Toro 33809

Well-Known Member

Plus I bet all the Merc owners on here are in awe... !

In awe and pumped that he is acquiring knowledge on the Merc's. It will be very helpful to us in the future.

Plus I bet all the Merc owners on here are in awe... !

Dr Honda

Sorry to intrude but I have a quick question I have a 2005 Islandia with a 250 optimax merc and tubers complain all the time about jet spray/wash hitting them in the face. I am using a 60ft tow rope and have tried a 70ft dosent seem to make a differance. Pulls fine with no issue and get up on plane quickly. Any help would be greatly appreciated....

A big job for sure. How hot is it in PA? Be sure to stay hydrated.

Looking good doc!!

Have yah got an eta on this rig hitting the lake?

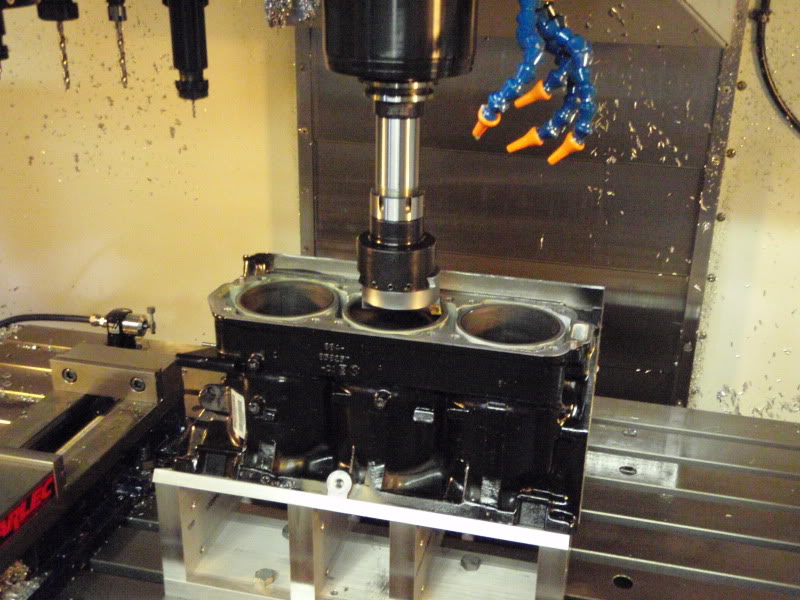

Yep... they come in handy. But... my 2 machines cost about the same as my house.Wow Beautiful!, must be nice having those machines!

How do you feel about them now?

3 weeks ago. (lol)

Realistically.... if I can get the block done this week... I can do the re-assembly... and then maybe get it back in the boat this weekend.?. BUT... as always... when I want to work on my own stuff, those dang customers bother me, wanting parts or service. (lol)

I guess if I can get it all warped up by the weekend of the 4th (aug) that would be OK with me.

GEEEEEZZZZZZZ.Those darn custromers constantly asking you to do things for them like cleaning out their carbs because they dont know how...LOL im glad im not one of them