Pistons are off.

and I almost got a heart attack. Seriously!

When i was working on the MAG side. The super magnet I put on the rod sucked one or two pins out in the air and landed on the cardboard cover I made. But I only found one on the cover. So I made myself believe only one pin flew out after 5 minutes carefully checking the cover and paper towel underneath.

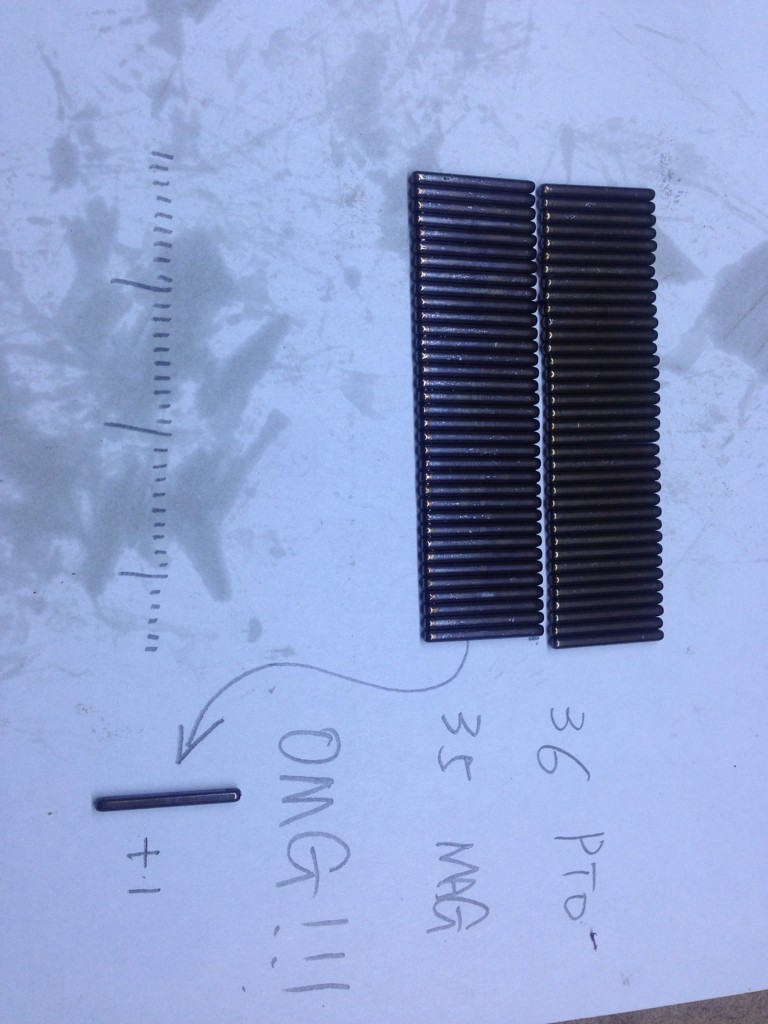

Ok back to my office to do counting!

36-35=1

OMG, Nooooooo.

I almost felt into the floor flat.

Counted twice and lined them up. Still math is correct, always.

Ok. With my heart stone cold, I went back into the bilge. Have you watched disassembling bomb in the field? I was like that peeling covers off from the crank case opening. Because I thought I saw one needle bounced into the corner of the cover and it was barely covering the opening.

Looked every inch I can see by my eyes and camera. No sign of A needle. Started to see if I can make a magnet fishing device, and checking the drawings to see the possibilities, and on and on for a minute.

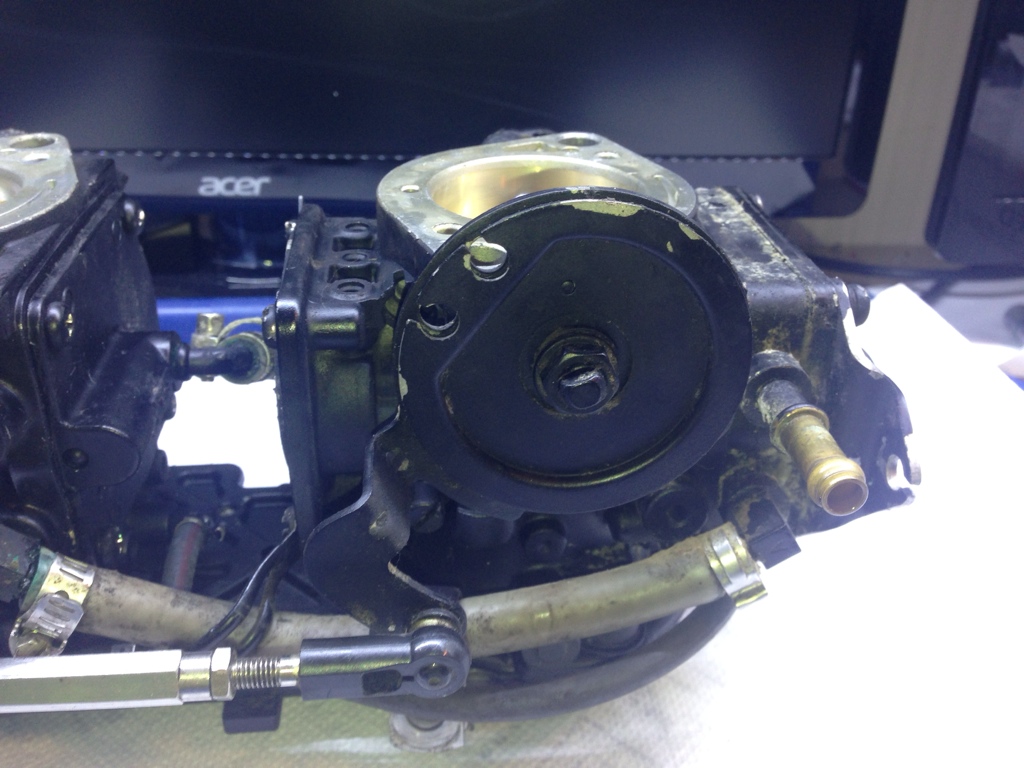

Heart was almost frozen. But just when I was about crawling (I have always been jumping) out of the bilge. I spot this

Is it a metal piece? Does it look like something I am looking for???

OMG, I did jump out of the bilge! Sit in the boat for one full minute. And took a picture and picked it up!

Now it is like this:

Warning:

1) you need a big heart ever do this type of work.

2) don't use super magnet try to hold the the needles together. In sportster le, you don't need a magnet actually. The needles just fall in to the piston cup. If you do want a magnet, use a normal one and let it lay on the bottom of the piston cup.

Edit:

3) Cover the opening well, seriously.

The end.

Sent from my iPhone using Tapatalk