What component(s) could cause an air leak past the carburators that would not have been pressure tested by SBT? Look over the service manual again. You installed them yourself.

When I went to SBT yesterday, I asked about the leak test, and they indicated leak test provided in the manual has been done.

Engine leak test begins at section 04-02-1 (page 69) of the Seadoo service manual PDF

which is used to diagnose engine problems such as poor performance, oil leakage, etc. prior to disassembly of the engine. However, the manual indicates static bench testing is the most effective way to conduct a leakage test which again is subject to

disassembly of the engine.

Removal of external components listed below are not disassembly of the engine. It is also important to note that is is required to remove some of the components below to get the motor out of the ski. So it appears a static bench test (without a prior test environmet setup such as that @ SBT) would be possible. To do a static bench test, the motor would need to be out of the ski. This test claims to test engine cooling system, bottom end, and top end for leaks,

prior to disassembly of the engine. The leak test kit even includes it's own hoses to test each component, so it's not like you're testing the hoses you're reinstalling which in and of themselves if not attached properly can cause leaks (note: page 70, "Use hoses provided in the kit and install them on the engine", etc.)

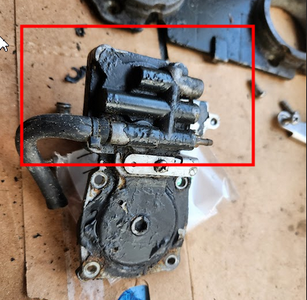

What gets installed back onto the engine core provided by SBT (and has been tested for leaks per the service manual specs prior to bolt on), all of which are arguably not parts of the engine itself:

Flywheel

Magneto

Bendix

Flywheel cover

PTO cover

PTO coupler

Starter

Reed valves

Reed valve covers

Exhaust manifold

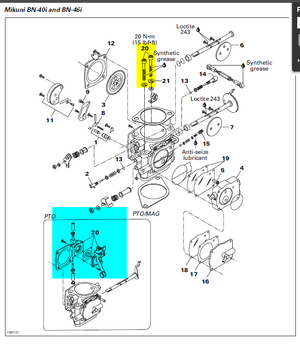

Carbs

Oil pump

Tuned pipe

Hoses connected to all of the above

Electrical connectors to all of the above

Choke/fuel

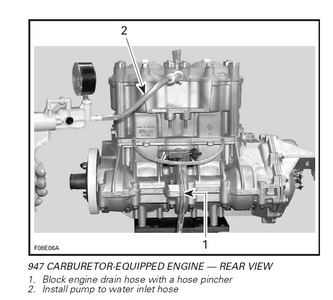

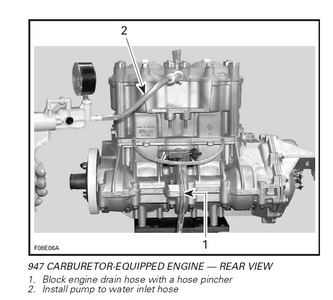

Page 71 of the manual shows describes blocking the engine drain hose with a hose pincher, (1), and installing the pump to the water hose inlet, note, the engine is already of the ski:

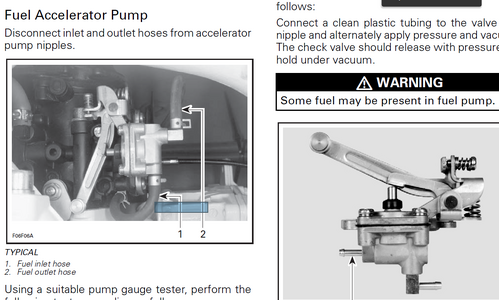

There are many leak tests throughout the manual for each component, which I'm obviously doing as I work on the given items, i.e., pressure test the carb pop-offs, test the fuel accelerated vaccuum, etc.

However, I reiterate again, the Seadoo service manual indicates the purpose of the main engine leak test is to test the INTERNAL components of the engine and crank case, and the second to the RAVE valves (RFI) which comes pre-installed other than the caps by SBT which begins on page .

The main engine leak test installs block off plates to several areas including:

Carb install location

Rave valve install location

Exhaust manifold after re-installation

Intake plates (covering reed valves)

If I were to remove rave valves to install block off plates this will void warranty (if any bolt or fastener is removed from the block provided).

I'm not quite sure how an exhaust manifold would leak with proper inspection, and installation including new gaskets and sealant since it is all one big composite structure.

Page 73, indicates to check items which have already been verified by SBT save the small injection oil pump lines , the exhaust manifold and the intake manifold. With regard to the oil pump lines and fittings for air bubbles -- they haven't installed that yet, and can't even be primed until connected to the feed line within the ski itself, and I don't have my engine hovering on an engine lift.

Is there perhaps another leak test, i.e., you are referring to, and can you provide a page within the Seadoo Service manual you are referring to which would confirm I need to do yet another leak test after bolt on of the external parts?