thejuice48

Active Member

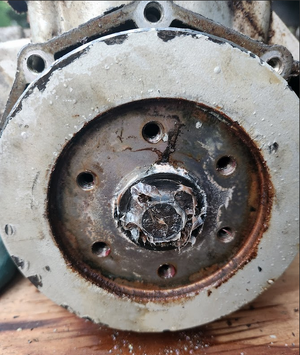

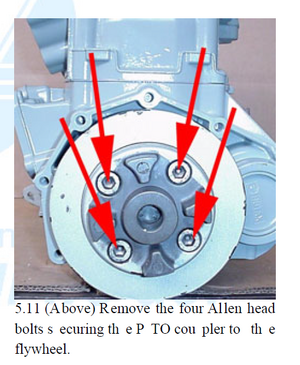

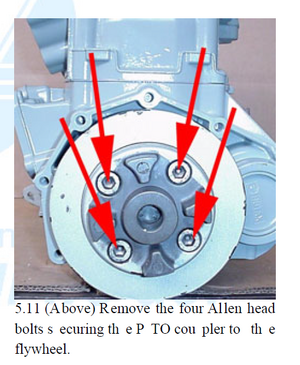

The instructions for removal for the PTO cover are different than what I'm experiencing....the destructions say 4 bolt holes, I have 6:

I removed the 6 bolts:

Then the instructions jump to removing the bolt without any instructions on taking the PTO coupling off. I assumed it would fall right off. Mine is very stuck (oh gee wonder why). I did order a new PTO coupler, but I will probably need the PTO bolt to put this thing back on, so unless I get at the PTO, how the F do I get this off? Perhaps I'm better off just ordering a new PTO coupler bolt so I stop wasting my time.

I just watched a video of a guy removing the PTO coupling with the motor in the ski using the impellar removal tool, and turning clockwise instead of counter?

I removed the 6 bolts:

Then the instructions jump to removing the bolt without any instructions on taking the PTO coupling off. I assumed it would fall right off. Mine is very stuck (oh gee wonder why). I did order a new PTO coupler, but I will probably need the PTO bolt to put this thing back on, so unless I get at the PTO, how the F do I get this off? Perhaps I'm better off just ordering a new PTO coupler bolt so I stop wasting my time.

I just watched a video of a guy removing the PTO coupling with the motor in the ski using the impellar removal tool, and turning clockwise instead of counter?

Last edited: