thejuice48

Active Member

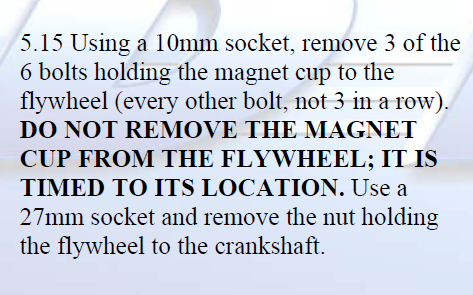

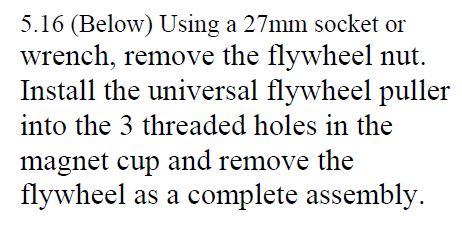

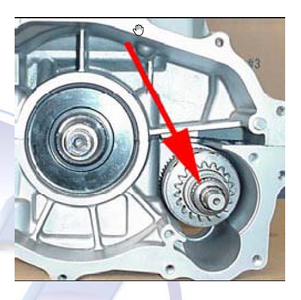

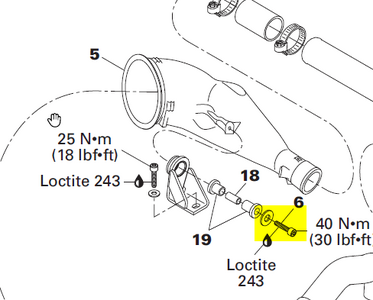

I soaked it in some Deep Creep, went back out there and used a pry bar wiggling it from every angle possible. The last few taps were with a small hammer. But it's out.No, do not remove that bolt. It holds the starter together and does not connect to the engine in any way.

Salt water skis are never fun to wrench on. Good luck my friend.

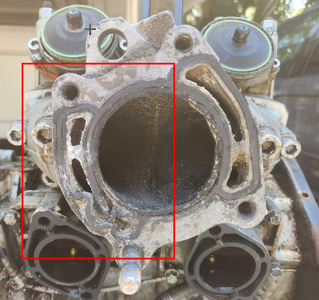

21? years on salt water. It doesn't look that bad compared to others I've seen:

After testing, it still works.

Gotta love CRC 6-56

Also found I have Prox flame arrestors. How do I clean these? I assume carb/choke cleaner can damage the rubber and plastic.

Last edited: