rjcress

Active Member

Ran the Challenger for another hour and a half yesterday. It did pretty good, but it is getting troubling that at higher throttle settings the engine bay fills up a bit... like 6-8 inches of water after 10 minutes, but when sitting or idling the engine bay stays pretty dry. I had trouble driving and looking even remotely closely at the engine for leaks last time, so I had my friend look while I drove this time. He couldn't find any leaks either. The water that fills the bilge is pretty hot, so I felt it must be leaking from the engine somewhere... just couldn't find it.

However, I tried one last time after hooking up to the trailer to take the boat home, but with the boat still in the water. Finally found water flowing from aft engine drain hose fitting (circled in pic)

It appeared to be leaking around the fitting itself. I'll see if I can wedge my hand and a wrench down in there to remove the fitting and see why it was leaking.

Other than that, it ran pretty well with me (200lb), my friend (230lb) and our two daughters (probably 130 lb between them), and 2/3 tank of gas.

After a few cycles on the new battery charger, the battery showed almost a volt higher in all modes than it did last time, topping out around 14.0V while cruising. Engaging the starter is easier than it was, but it still doesn't immediately engage every time I push the start button. Sometimes I have to hold the start button for a few seconds before the starter starts spinning. I have a spare starter, but wanted to see how it did with the battery after it had been through a few desulfation cycles on the new charger. I tested the starter solenoid near the end of last season, and it tested fine, but I'll check it again. Also need to verify that all of the engine ground connections are good.

Noticed a new issue though, this time. Both on the trailer at home and once in the water it took a lot of cranking to get it to start. Probably 25-30 seconds. The first few times I started it this year it was nearly instant, while choked, with the throttle at idle. Before I get too worried, I'll check the spark plugs, as the engine had about 6.5 hours on it after the prior trip, including running with extra oil in the pre-mix during break-in, and I haven't looked at the plugs yet this season (I know... I should have).

In other news, I got the new upholstery on the spotter seat this week and ordered all new external decals. For budget reasons, I stuck with single color silver vinyl decals. The new registration numbers arrived today, as well one of the 2 sets of these that I ordered:

http://www.ebay.com/itm/221431167916 One of these will go on each side of the engine bay hatch, and one on each side of the trailer frame.

I'll put one of these on the transom, and one diagonally across the little fake windscreen-ish bubble on the hatch forward of the helm:

http://www.ebay.com/itm/111374029866 (likely without the dophin)

And one of these on each side of the hull:

http://www.ebay.com/itm/111355638047

Got to pick up something to clean the muddy water stains off of the hull sides before the big ones on.

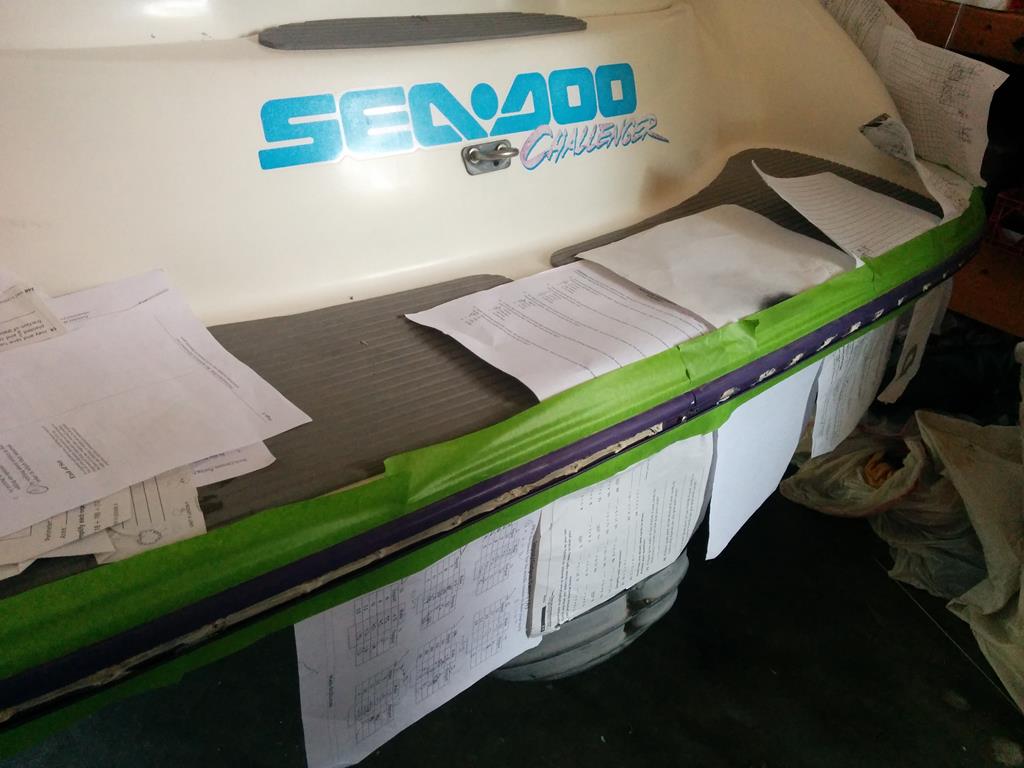

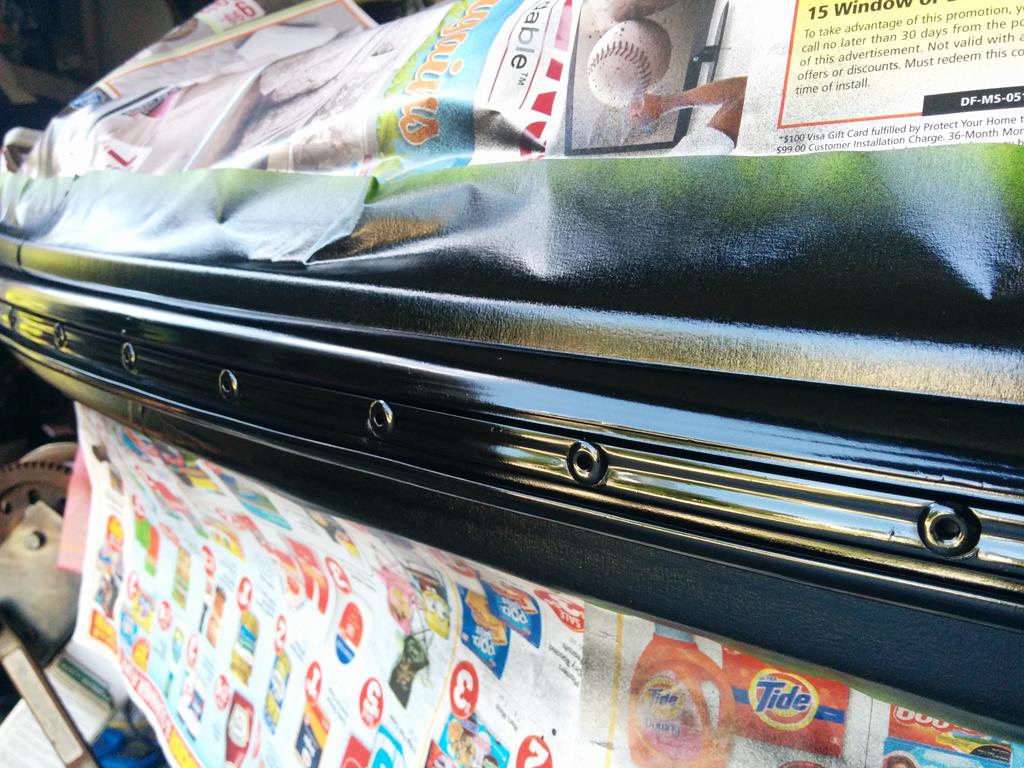

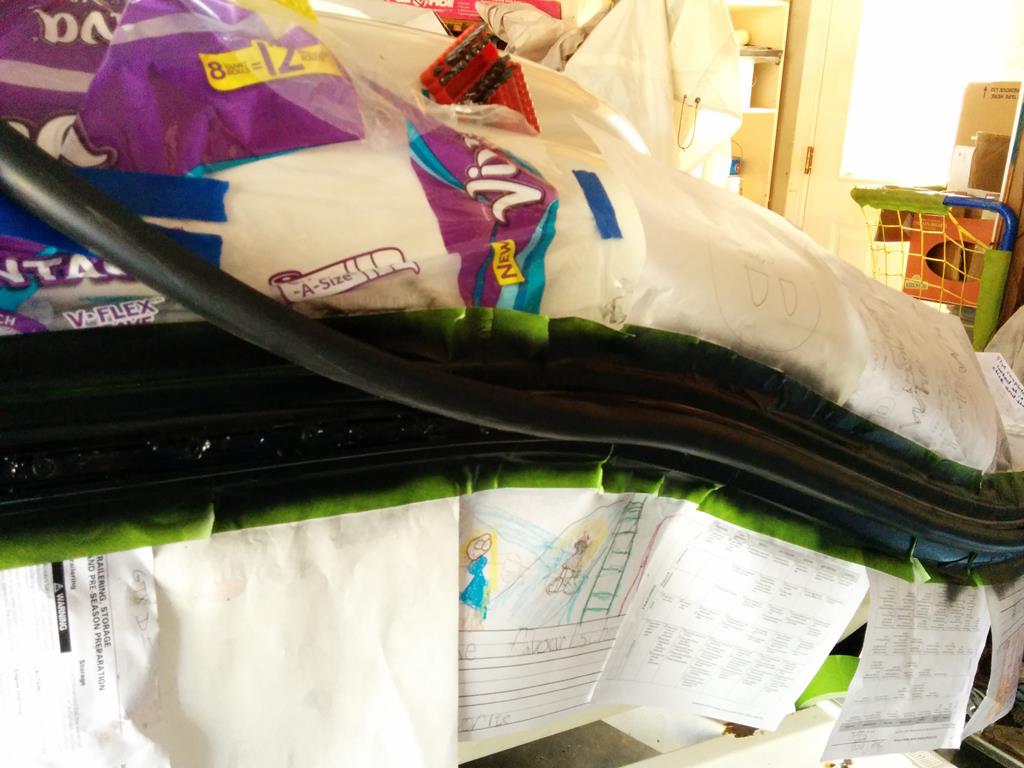

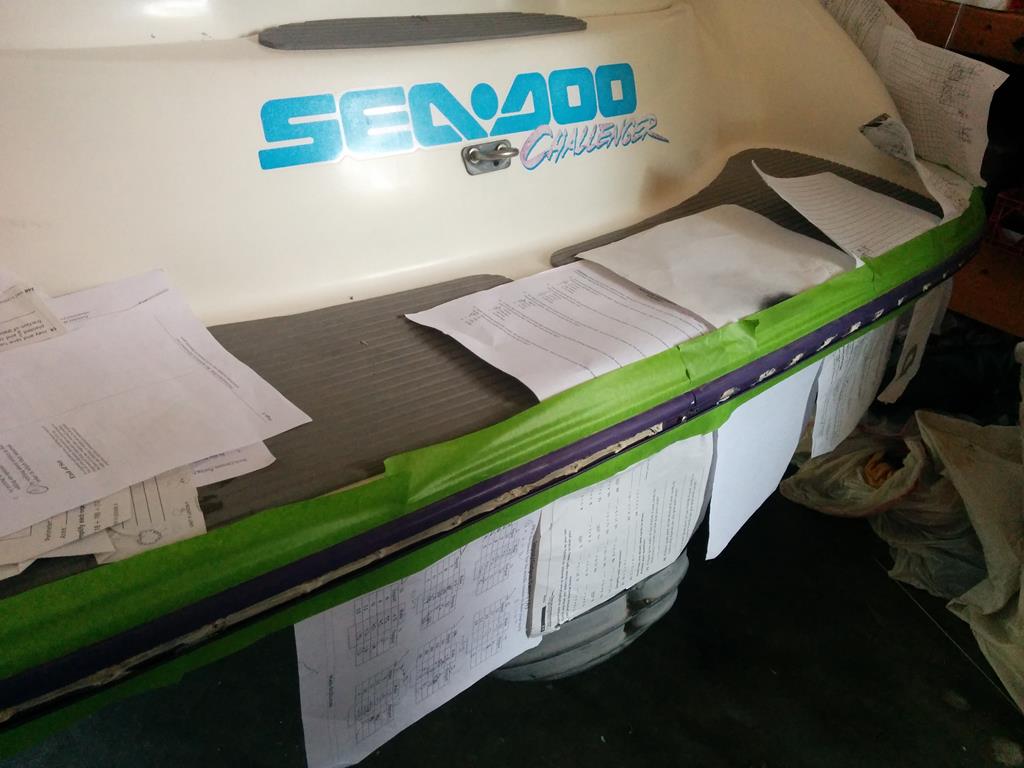

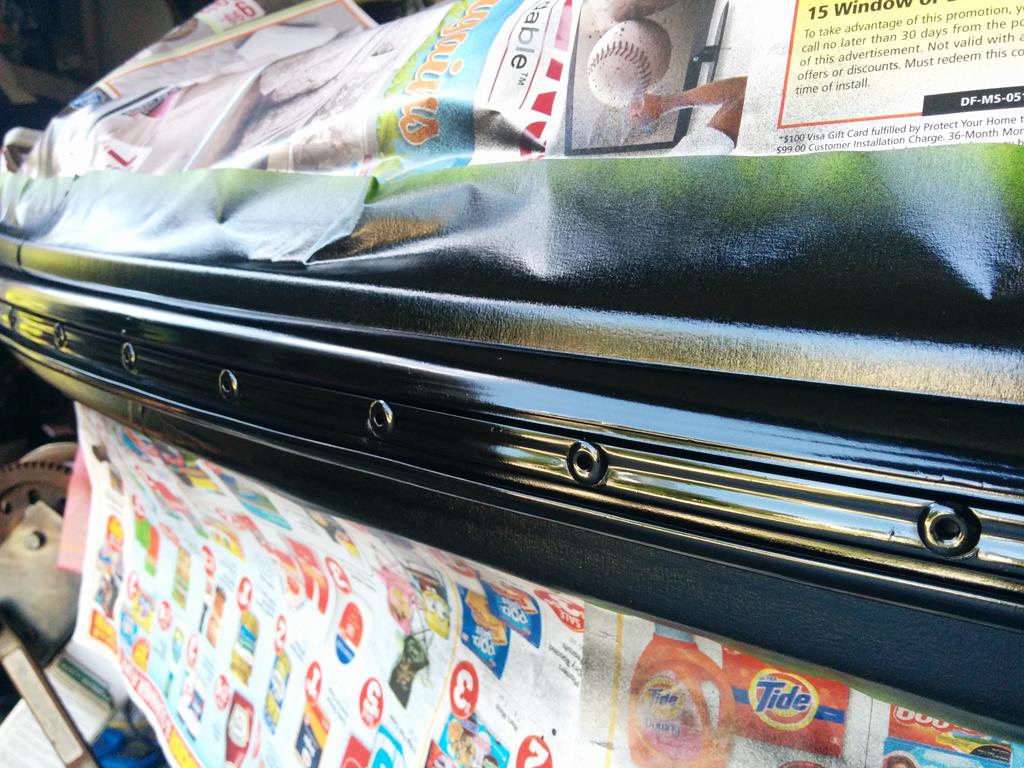

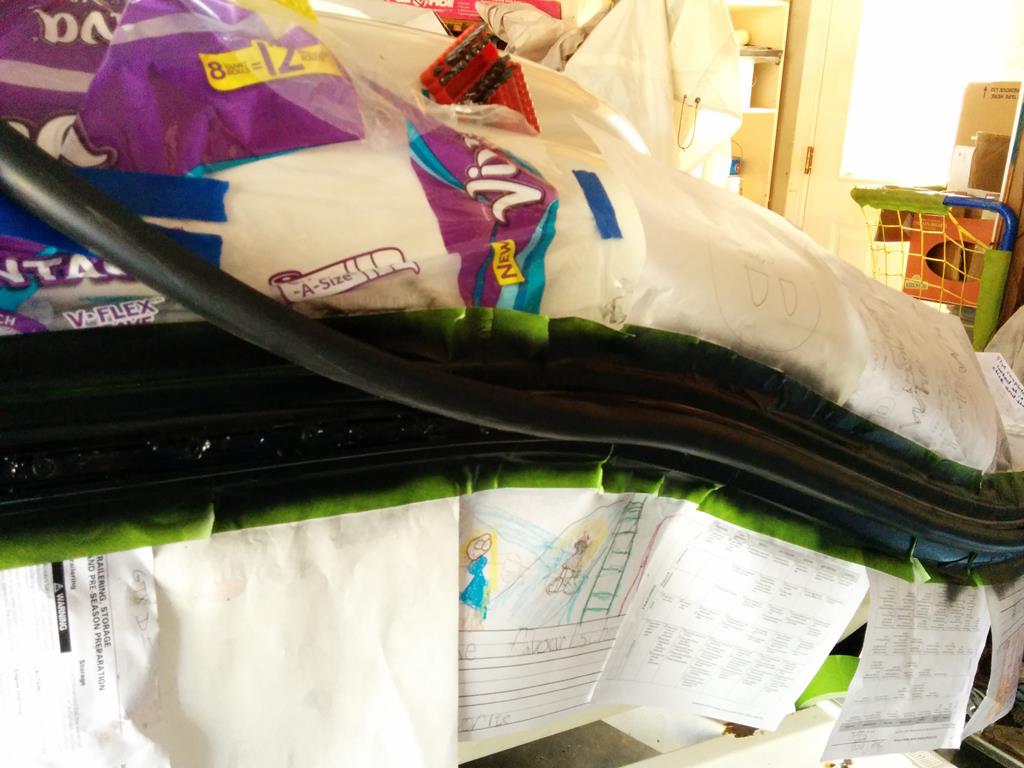

Some pics from the rub rail channel painting and rub rail insert installation...

Note that I am an avid recycler, but consider it a double win if I can reuse something before recycling it. So... the frog tape is new, but all of the plastic and paper used to shield the boat from overspray were recycled. Much of which were old school papers from my kids. This is proof that the math teacher was correct when she said that those math problems would be used again outside of the classroom.

Oh, and notice that I also painted the grab handles. Well, I've since stripped all of the paint off of the handles since it didn't cure. It was still tacky 3 days after painting.

1 Taping off the rub rail channel

2 Tape + plastic

3 damp sponge along the edge to seal the frog tape

4 first section sprayed

5 hmmm. didn't get that section clean enough. had to clean is off and reshoot it later

6 this section came out good on the first pass

7 taping around the curves

8 FINALLY! A good use for math homework

9 I know I am biased, but I think this turned out awesome

10 and around the back corner

12 port side

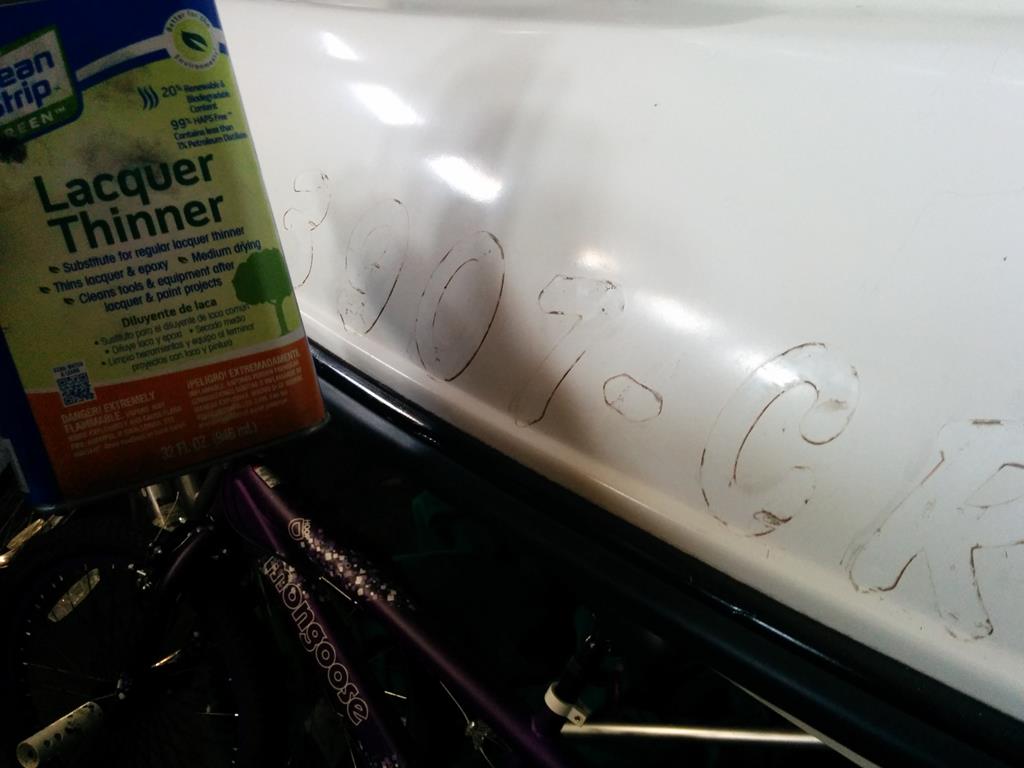

13 cleaned handles in lacquer thinner, then sprayed with krylon fusion. Was a complete bust.

14 installing the new rub rail insert

15 installing the new rub rail insert

16 insert lined up and ready to be squeezed and poked into the channel

17 Rub rail installed on port side

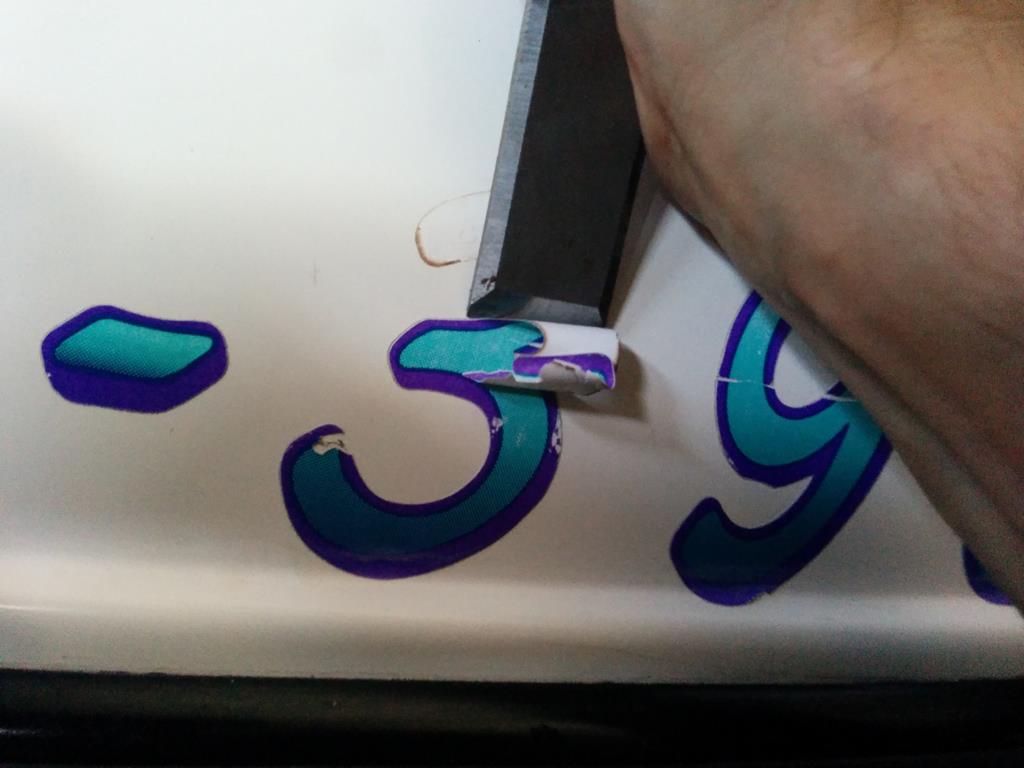

18 scraping off little bits of paint that seeped under the frog tape

19 painting a handle that wouldn't come off

20 Rub rail channel painted and rubber insert installed :drool5:

:drool5:

However, I tried one last time after hooking up to the trailer to take the boat home, but with the boat still in the water. Finally found water flowing from aft engine drain hose fitting (circled in pic)

It appeared to be leaking around the fitting itself. I'll see if I can wedge my hand and a wrench down in there to remove the fitting and see why it was leaking.

Other than that, it ran pretty well with me (200lb), my friend (230lb) and our two daughters (probably 130 lb between them), and 2/3 tank of gas.

After a few cycles on the new battery charger, the battery showed almost a volt higher in all modes than it did last time, topping out around 14.0V while cruising. Engaging the starter is easier than it was, but it still doesn't immediately engage every time I push the start button. Sometimes I have to hold the start button for a few seconds before the starter starts spinning. I have a spare starter, but wanted to see how it did with the battery after it had been through a few desulfation cycles on the new charger. I tested the starter solenoid near the end of last season, and it tested fine, but I'll check it again. Also need to verify that all of the engine ground connections are good.

Noticed a new issue though, this time. Both on the trailer at home and once in the water it took a lot of cranking to get it to start. Probably 25-30 seconds. The first few times I started it this year it was nearly instant, while choked, with the throttle at idle. Before I get too worried, I'll check the spark plugs, as the engine had about 6.5 hours on it after the prior trip, including running with extra oil in the pre-mix during break-in, and I haven't looked at the plugs yet this season (I know... I should have).

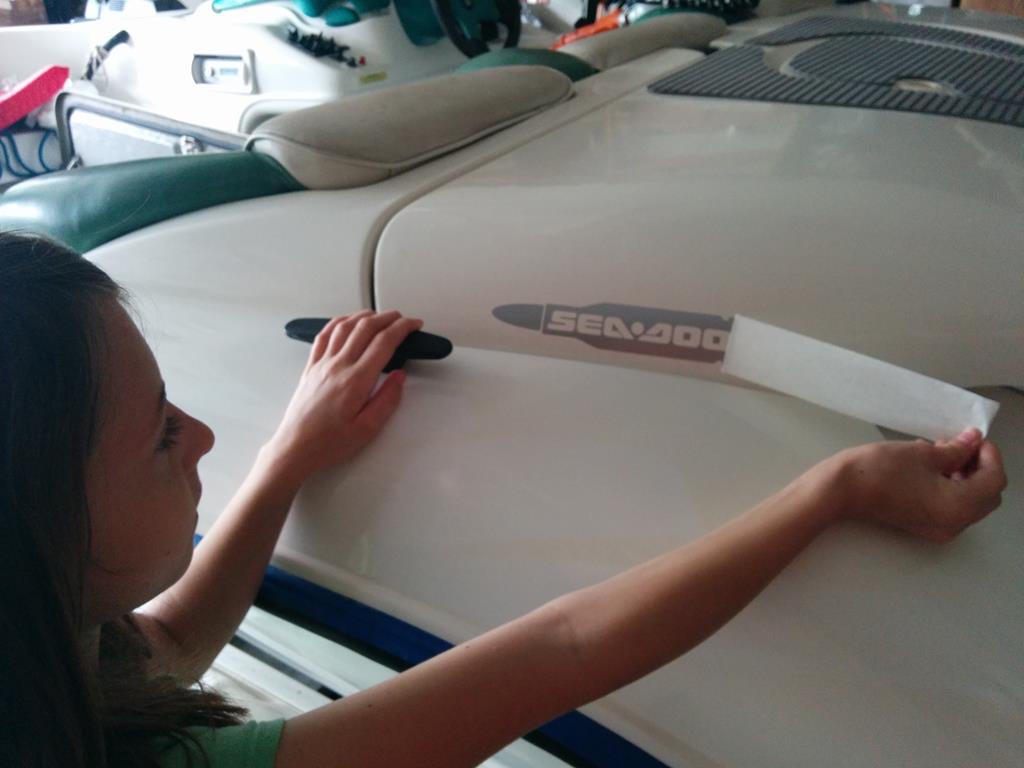

In other news, I got the new upholstery on the spotter seat this week and ordered all new external decals. For budget reasons, I stuck with single color silver vinyl decals. The new registration numbers arrived today, as well one of the 2 sets of these that I ordered:

http://www.ebay.com/itm/221431167916 One of these will go on each side of the engine bay hatch, and one on each side of the trailer frame.

I'll put one of these on the transom, and one diagonally across the little fake windscreen-ish bubble on the hatch forward of the helm:

http://www.ebay.com/itm/111374029866 (likely without the dophin)

And one of these on each side of the hull:

http://www.ebay.com/itm/111355638047

Got to pick up something to clean the muddy water stains off of the hull sides before the big ones on.

Some pics from the rub rail channel painting and rub rail insert installation...

Note that I am an avid recycler, but consider it a double win if I can reuse something before recycling it. So... the frog tape is new, but all of the plastic and paper used to shield the boat from overspray were recycled. Much of which were old school papers from my kids. This is proof that the math teacher was correct when she said that those math problems would be used again outside of the classroom.

Oh, and notice that I also painted the grab handles. Well, I've since stripped all of the paint off of the handles since it didn't cure. It was still tacky 3 days after painting.

1 Taping off the rub rail channel

2 Tape + plastic

3 damp sponge along the edge to seal the frog tape

4 first section sprayed

5 hmmm. didn't get that section clean enough. had to clean is off and reshoot it later

6 this section came out good on the first pass

7 taping around the curves

8 FINALLY! A good use for math homework

9 I know I am biased, but I think this turned out awesome

10 and around the back corner

12 port side

13 cleaned handles in lacquer thinner, then sprayed with krylon fusion. Was a complete bust.

14 installing the new rub rail insert

15 installing the new rub rail insert

16 insert lined up and ready to be squeezed and poked into the channel

17 Rub rail installed on port side

18 scraping off little bits of paint that seeped under the frog tape

19 painting a handle that wouldn't come off

20 Rub rail channel painted and rubber insert installed