-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Challenger 4tec Upgrade

- Thread starter IDoSeaDoo

- Start date

- Status

- Not open for further replies.

IDoSeaDoo

Well-Known Member

It's a positive displacement pump of some sort. Cheap little thing, just like the one you had. Sucks the oil pretty well. Just can't get to all the nooks and crannies of the engine block (obviously)Out of curiosity what are you using to suck the oil out? Electric pump or vacuum pump? I never had good luck with the electric oil pumps personally.

IDoSeaDoo

Well-Known Member

Alright, FINALLY! The oil fiasco is behind me. Yesterday, I put in my freshly boiled oil from the night before and ran the motor. I hooked the motor back to the hose (having plugged the PTO with a special plug I made) and just ran it for a while, the whole time monitoring head and exhaust temps. I sucked out some oil to inspect the color and it was still a dark brown. It was time for the boil out procedure!

Once it was warm, I put a hose pincher on the rear-most hose going to the oil cooler and continued to run the motor at ~3000rpm. I did this for about 5-10min vs the prescribed 15 in the manual, as I'd already boiled most of the water out. I had the dipstick up a few inches to allow the crank case to better vent. For some reason, the regular PCV vent usually stays closed. That seems rather strange to me, I wonder how it's supposed to work...

Anyway, after running a while with the Oil cooler pinched, I shut it down. Engine temps on the head and PTO reached almost 200F, which I figure is the higher threshold of Normal Operating Temp. I sucked out the oil, and it still looked nice and dark brown. No paper towel particles or milkyness to it. It had a little of that silver aluminum powder, but now that I know where it's coming from, I'm not worried.

After draining the abused oil, I put in 4 quarts of fresh oil and a new filter. She runs good and revs strong, but she doesn't idle steady. The RPMS both at IDLE and any certain setting seem to wander about 100rpm. Maybe it's because the throttle cable is loose. Anyway, I put fresh plugs in it, and it didn't change anything. I just remembered about the cable and will tighten it tonight.

I realigned the motor and it's ready for final reassembly. This weekend, I MIGHT go and test it. I'm no longer making any promises to myself, or allowing for any excitement. I've had my hopes smashed twice now, and would not be surprised by ANYTHING anymore.

Once it was warm, I put a hose pincher on the rear-most hose going to the oil cooler and continued to run the motor at ~3000rpm. I did this for about 5-10min vs the prescribed 15 in the manual, as I'd already boiled most of the water out. I had the dipstick up a few inches to allow the crank case to better vent. For some reason, the regular PCV vent usually stays closed. That seems rather strange to me, I wonder how it's supposed to work...

Anyway, after running a while with the Oil cooler pinched, I shut it down. Engine temps on the head and PTO reached almost 200F, which I figure is the higher threshold of Normal Operating Temp. I sucked out the oil, and it still looked nice and dark brown. No paper towel particles or milkyness to it. It had a little of that silver aluminum powder, but now that I know where it's coming from, I'm not worried.

After draining the abused oil, I put in 4 quarts of fresh oil and a new filter. She runs good and revs strong, but she doesn't idle steady. The RPMS both at IDLE and any certain setting seem to wander about 100rpm. Maybe it's because the throttle cable is loose. Anyway, I put fresh plugs in it, and it didn't change anything. I just remembered about the cable and will tighten it tonight.

I realigned the motor and it's ready for final reassembly. This weekend, I MIGHT go and test it. I'm no longer making any promises to myself, or allowing for any excitement. I've had my hopes smashed twice now, and would not be surprised by ANYTHING anymore.

snikwad003

Well-Known Member

Where you gonna test it if you do

IDoSeaDoo

Well-Known Member

Jordan lake. They have a nice large 4 boat ramp. I'll need one slip for quite a while as I put in and verify no leaks and that it can cool itself.Where you gonna test it if you do

IDoSeaDoo

Well-Known Member

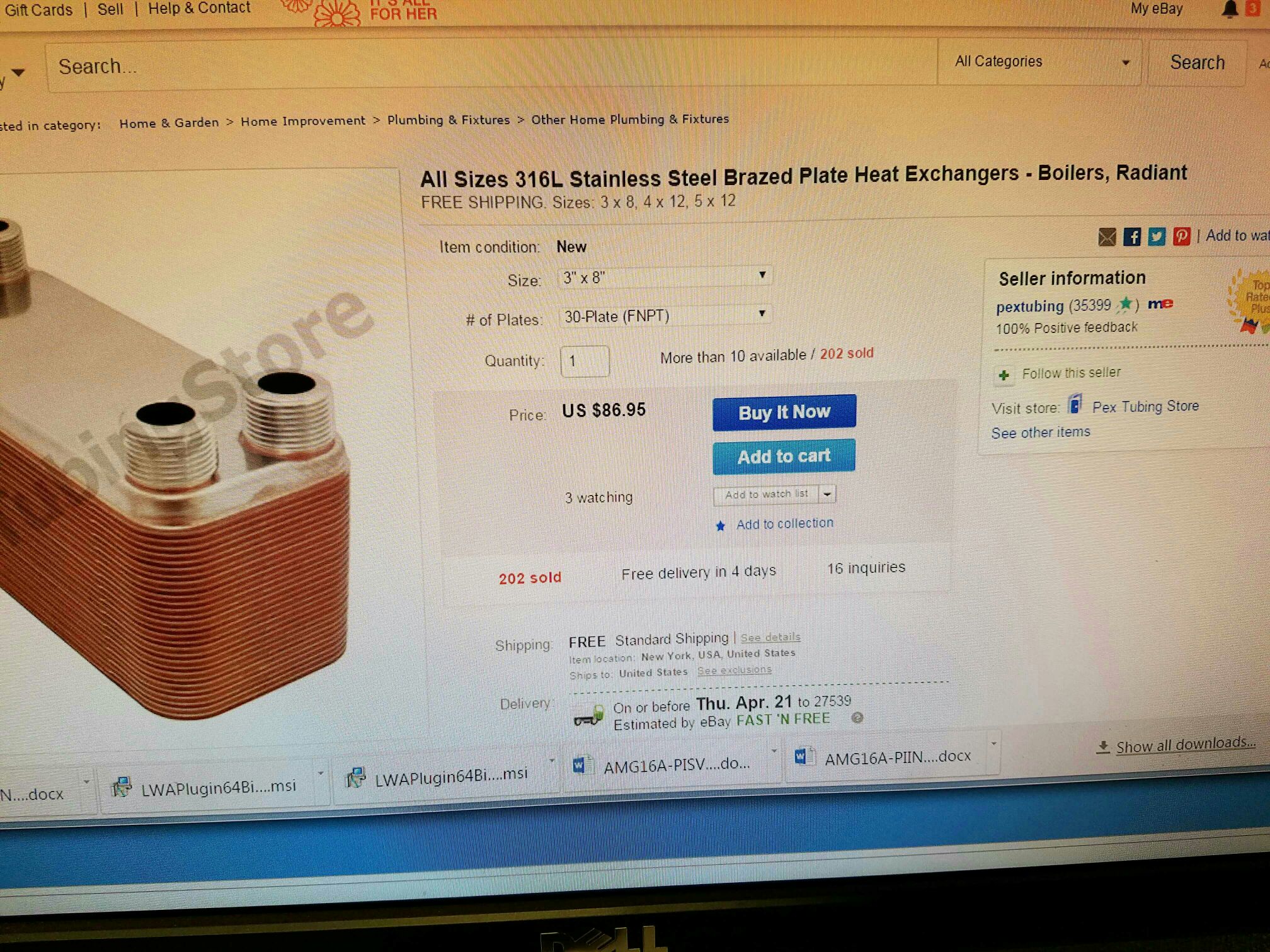

I believe it was the 3x8 30plate. I used fnpt, as is easier to come by the fittings. Lowe's has them for $1/piece in the sprinkler section.Awesome! Glad to hear things are looking up. Ill be pretty interested to hear how your cooler setup works out. I'm hoping to do the exact same thing on my setup. What size did you end up with 3"x8"x30plates or did you get the 12"?

Don't have a better size reference at the moment. I'll measure it when I get home.

Here's one on ebay just like the one I have

Man, it's crazy how hot the engine bay becomes with that monster running. The fuel tank registered at 103F after the boil out procedure. I may choose to always run the blower during operation.

Last edited by a moderator:

dcia3231

Member

That seems awful how to me. Wonder how the 4 tecs vent heat??? i dont recall either of us ever measuring the 2 stroke temps. We might be able to get a really rough reading from my sk. i highly doubt it gets to 103 degrees then again .... you are attempting to bleed alot of the heat in the engine bay which is insulated now.

wfo speedracer

Active Member

That seems awful how to me. Wonder how the 4 tecs vent heat??? i dont recall either of us ever measuring the 2 stroke temps. We might be able to get a really rough reading from my sk. i highly doubt it gets to 103 degrees then again .... you are attempting to bleed alot of the heat in the engine bay which is insulated now.

He said he measured it after the boil out procedure, a procedure where you are running the engine hotter than normal to boil the remaining water out of the oil. I doubt under actual running conditions it would ever get near this temp inside the engine bay.

Sportster-2001-951C-Stock

Well-Known Member

One more thing to keep in mind as far as water in the oil isconcerned, if it's antifreeze as opposed to just clear water there's a much higher chance of bearing damage sue to the silicon content of antifreeze I guess. I can for sure tell you engine oil contaminated with antifreeze will eat bearings MUCH faster than just some plain water.

I guess you can overnight drain most of the water out of an oil filter, if you're just trying to get water out. I always just use the cheapest fresh motor oil for the 3`4x flush and then tell them to run it ASAP for a few hours and keep watch.

I guess you can overnight drain most of the water out of an oil filter, if you're just trying to get water out. I always just use the cheapest fresh motor oil for the 3`4x flush and then tell them to run it ASAP for a few hours and keep watch.

snikwad003

Well-Known Member

Did it run good?

dbechth

Member

IDoSeaDoo

Well-Known Member

It ran GREAT! Of course there were a few snags, but the boat is a BEAST!! :thumbsup: We finally put her in Saturday. I finished the wiring and tested all the circuits, got a big box of tools together and off we went. The steering cable was a pain, the linkage kept binding when you turn it all the way. That made it especially tricky near the dock when cranking all the way triggers the RPMS to increase. It was seadoo's answer to make the boats more maneuverable at idle. Works well if the steering is free

Anyway, we got out and just idled around, keeping a close eye on temps and leaks. Then I started playing around with the throttle The boat experienced a lot of cavitation. You can't punch it from Idle, it just spins the prop and bounces off the rev limiter. I suspect a badly sealed ride-plate. I'll fix that once my gel-coat dye comes in. I want to gel coat the bottom of it. The top is painted with automotive 2-stage.

The boat experienced a lot of cavitation. You can't punch it from Idle, it just spins the prop and bounces off the rev limiter. I suspect a badly sealed ride-plate. I'll fix that once my gel-coat dye comes in. I want to gel coat the bottom of it. The top is painted with automotive 2-stage.

Once the boat is on plane though, it's a monster. Forgetting I had the trim up, I floored it. It got up into the 50s, but started getting all squirrely. I eased her back down, adjusted the trim and floored again. She topped out at 50mph that way. I'll experiment more when I'm more used to it

Anyway, I noticed that oil was again seeping from around the valve cover. I pulled the dipstick, and it blew off a ton of air pressure, along with some oil. Made a huge mess. The TOPS valve is shot. I tested power, and it is getting it, but when you plug it in, it just makes a weak whining shuttering sound. I'll probably just take it apart and gut it. I don't see a use for it anymore, since this boat will not be turning over much.

My fears about the cable snapping were realized on the first trip out. The binding was a result of the cable bending as the steering assembly pulls it out. This repeated bending finally caused it to snap. Luckily we were right near the dock, and there were almost no other boats around, so we used the engine in short bursts to propel us fwd while I steered with an oar I've already installed the original cable and calibrated it. Had to bore the thru-hull hole in the plastic pump base plate.

I've already installed the original cable and calibrated it. Had to bore the thru-hull hole in the plastic pump base plate.

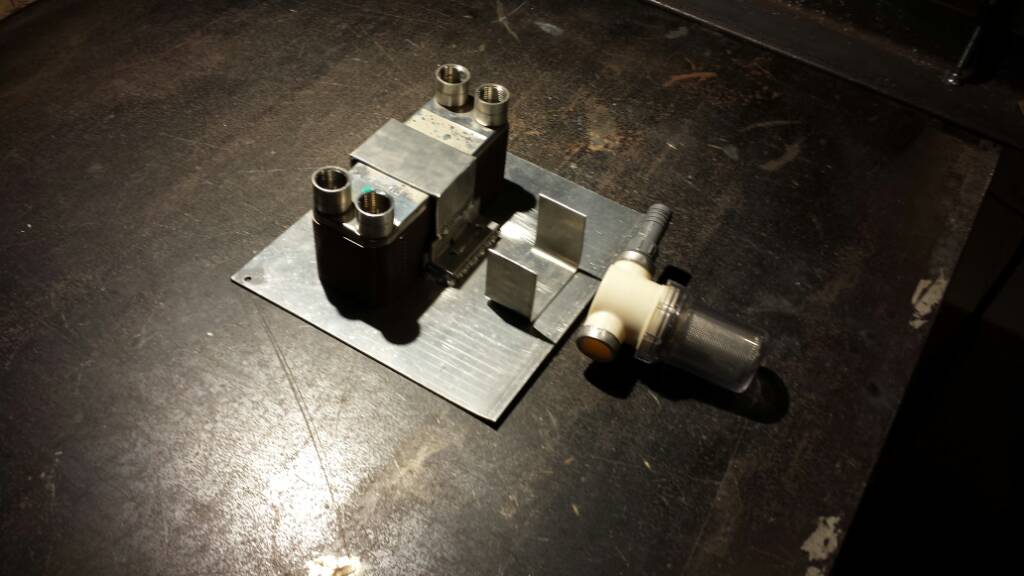

I also finished the heat exchanger mount bracket and cut the OE hoses to fit the new configuration. It all rits rather nicely. Just got to finish securing that to the hull and mount the strainer, and that's done.

Also, I fully tested the fuel tank for leaks by filling it up and driving around with it (some 40 miles or so). No leaks anywhere! I plan to take her back out tomorrow after I sort the TOPS issue out, and seal up the leaking drain plugs.

Video will come later today once I find non-restricted WIFI.

Anyway, we got out and just idled around, keeping a close eye on temps and leaks. Then I started playing around with the throttle

Once the boat is on plane though, it's a monster. Forgetting I had the trim up, I floored it. It got up into the 50s, but started getting all squirrely. I eased her back down, adjusted the trim and floored again. She topped out at 50mph that way. I'll experiment more when I'm more used to it

Anyway, I noticed that oil was again seeping from around the valve cover. I pulled the dipstick, and it blew off a ton of air pressure, along with some oil. Made a huge mess. The TOPS valve is shot. I tested power, and it is getting it, but when you plug it in, it just makes a weak whining shuttering sound. I'll probably just take it apart and gut it. I don't see a use for it anymore, since this boat will not be turning over much.

My fears about the cable snapping were realized on the first trip out. The binding was a result of the cable bending as the steering assembly pulls it out. This repeated bending finally caused it to snap. Luckily we were right near the dock, and there were almost no other boats around, so we used the engine in short bursts to propel us fwd while I steered with an oar

I also finished the heat exchanger mount bracket and cut the OE hoses to fit the new configuration. It all rits rather nicely. Just got to finish securing that to the hull and mount the strainer, and that's done.

Also, I fully tested the fuel tank for leaks by filling it up and driving around with it (some 40 miles or so). No leaks anywhere! I plan to take her back out tomorrow after I sort the TOPS issue out, and seal up the leaking drain plugs.

Video will come later today once I find non-restricted WIFI.

Eclipse1701d

New Member

Congrats!!!

IDoSeaDoo

Well-Known Member

Thanks guys, ya, I'm on cloud 9 this whole weekend. It's soooo good to have finally proven the concept. I had this irrational fear that the hull would not hold up and just crank out.

I thrashed it about some to give the hull a good test. It held up perfectly. No cracks in the gel coat at all. I feel good about the integrity of the graft now.

I thrashed it about some to give the hull a good test. It held up perfectly. No cracks in the gel coat at all. I feel good about the integrity of the graft now.

snikwad003

Well-Known Member

Nice work man. I hope to see this thing in person on one of these lakes around here.

IDoSeaDoo

Well-Known Member

That West System epoxy had some good reviews. I did my homework before buying the resin. This is supposedly the best and strongest stuff on the commercial market to build boats from.i was thinking the same thing. Fiberglass is strong but i had that fear as well. i doubt they designed that boat to handle 185hp. So glad you over engineered it

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 236

- Replies

- 4

- Views

- 591

- Replies

- 1

- Views

- 335

- Replies

- 1

- Views

- 256

Share: