glsmohio

Well-Known Member

Yep looks good. Thanks for taking the time to test it.

The only reason I suggested to do windex was for the color, a couple of drops of food coloring would work in the alcohol too.

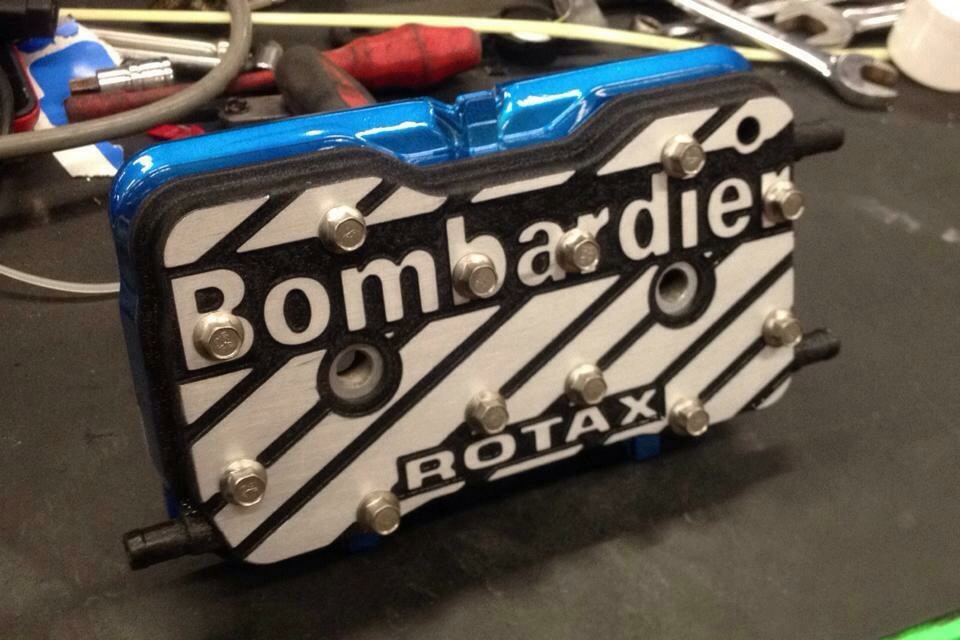

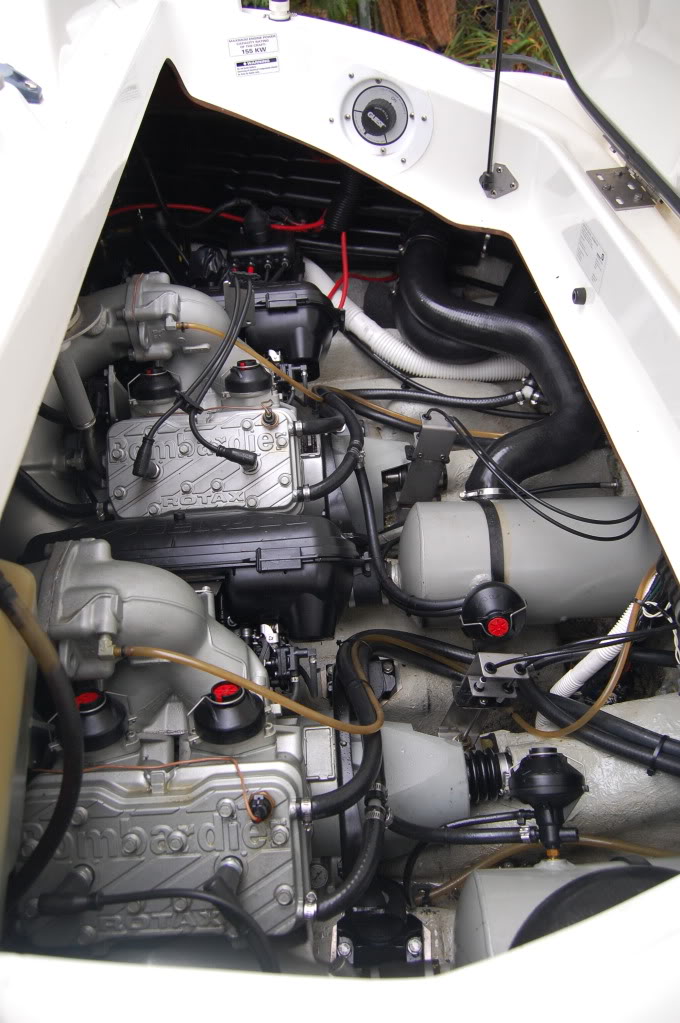

It would be nice to see an SBT head measured too to verify they are cutting for increased cc.

Sent from my iPhone using Tapatalk

ill do that tonight, it was just getting late last night. I dont even think i need to test the cc of the SBT head lol, Ill post a pic of the stock head , Group K head and the sbt head (all in a row), you can see where they cut the head right at the squish band (its like a damn step)