Bonmotwang

Well-Known Member

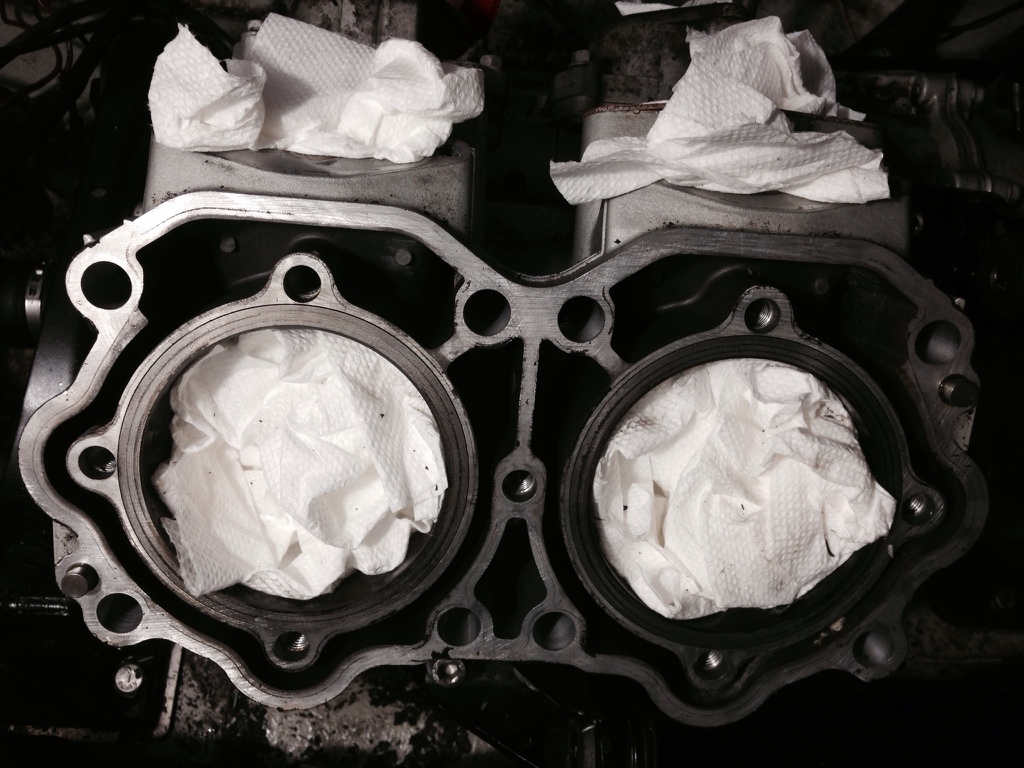

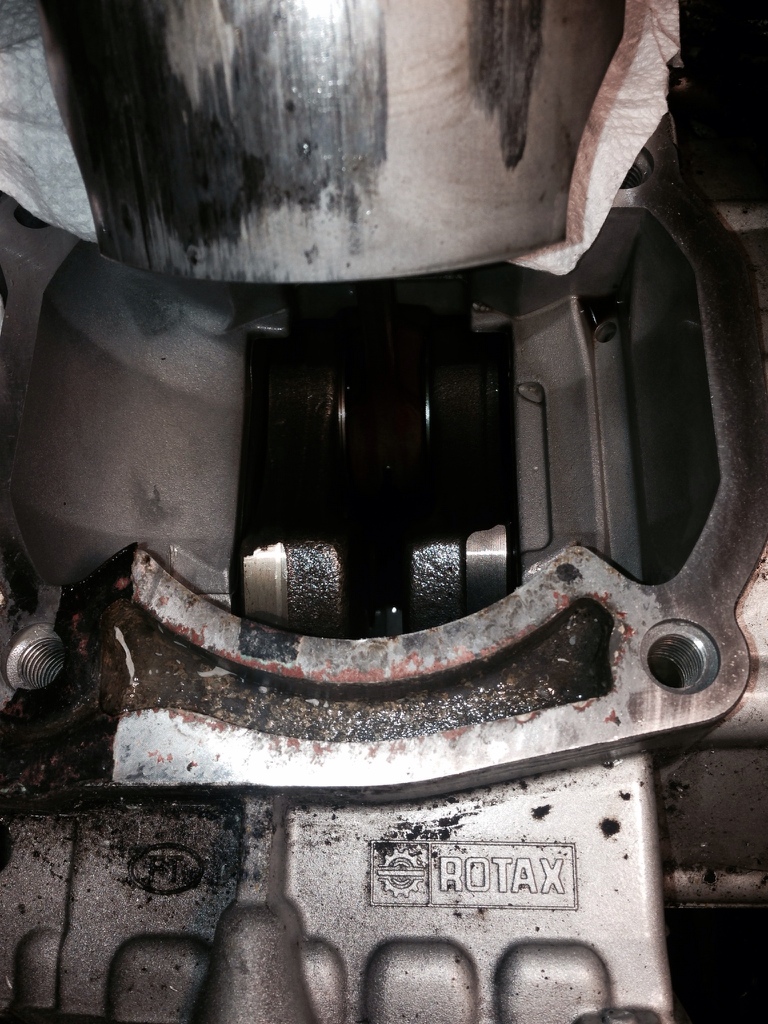

OK, the manifold is off. Cylinder is still in place, couldn't get it loose yet. Call the day.

But I feel the piston skirt through the exhaust ports. You know what? they are as smooth as the cylinder wall!

Well first thought everyone would have is, what are the lines and colors.

I guess the colors are from the rust from sitting during the winter.

The lines I think is from the somehow touching the cylinder wall just a little of course with the oil film in between, otherwise it will be rough.

Also the normal heat and high pressure air leaking through the ring and blow on the skirt surface and causing the lines.

Anyway, I see this is a good news.

First of all, pistons look good and feel very smooth, so there hasn't been aluminum loss happened yet, or at least at the level I couldn't feel.

Second, we think we found out why the PTO piston has more lines than the MAG piston. The reason is the carb seal on the PTO side was off.

It was a long night. But fun! Touched something I may never be touching in my life! I love it.

A puzzle for you guys: how did I get the manifold off with the tuned pipe in the way? I will post pictures in 7 days.:lol:

Back to practical things:

Sportster's boat has the same compression as mine. so his top end condition is probably same as mine except no surface lines. It runs great. and without seeing those lines through the RAVEs, I feel the same :thumbsup:

I will clean up and rebuild the carbs for sure, I have the kit and the carbs are out.

Need your suggestions for the top end and consider my friends (OMG, my wife's friends!!!) are coming Aug 2nd. She told me today she had planned picnic at the beach with other 2 families. My heart was dropping like a mop at a moment:facepalm: But not big deal. Many other things to do on the beach anyway.

So I keep going and knock the cylinder loose and inspect the low end?

And package up the top end and send out to be rebuilt? Is cylinder boring a super high precision high tech? Can I try the ex seadoo dealer locally if their price is around $500 and timing is OK?

Thanks guys. No beer tonight, too tired. my Thinkpad is getting oily too, same as my iPhone, and my hand, and my face ... ZZzzzz too tired for a shower ... But hmmm, smooth pistons ... ...

But I feel the piston skirt through the exhaust ports. You know what? they are as smooth as the cylinder wall!

Well first thought everyone would have is, what are the lines and colors.

I guess the colors are from the rust from sitting during the winter.

The lines I think is from the somehow touching the cylinder wall just a little of course with the oil film in between, otherwise it will be rough.

Also the normal heat and high pressure air leaking through the ring and blow on the skirt surface and causing the lines.

Anyway, I see this is a good news.

First of all, pistons look good and feel very smooth, so there hasn't been aluminum loss happened yet, or at least at the level I couldn't feel.

Second, we think we found out why the PTO piston has more lines than the MAG piston. The reason is the carb seal on the PTO side was off.

It was a long night. But fun! Touched something I may never be touching in my life! I love it.

A puzzle for you guys: how did I get the manifold off with the tuned pipe in the way? I will post pictures in 7 days.:lol:

Back to practical things:

Sportster's boat has the same compression as mine. so his top end condition is probably same as mine except no surface lines. It runs great. and without seeing those lines through the RAVEs, I feel the same :thumbsup:

I will clean up and rebuild the carbs for sure, I have the kit and the carbs are out.

Need your suggestions for the top end and consider my friends (OMG, my wife's friends!!!) are coming Aug 2nd. She told me today she had planned picnic at the beach with other 2 families. My heart was dropping like a mop at a moment:facepalm: But not big deal. Many other things to do on the beach anyway.

So I keep going and knock the cylinder loose and inspect the low end?

And package up the top end and send out to be rebuilt? Is cylinder boring a super high precision high tech? Can I try the ex seadoo dealer locally if their price is around $500 and timing is OK?

Thanks guys. No beer tonight, too tired. my Thinkpad is getting oily too, same as my iPhone, and my hand, and my face ... ZZzzzz too tired for a shower ... But hmmm, smooth pistons ... ...