-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

97 Seadoo Spx build

- Thread starter glsmohio

- Start date

- Status

- Not open for further replies.

glsmohio

Well-Known Member

Is that a Spec 2?

spec1, but kinda wish i would of went with sec 2

Krispy

Well-Known Member

spec1, but kinda wish i would of went with sec 2

http://factorypipe.com/media/instructions/seadoo/785XP05.pdf

Why are you regretting the spec 1 decision?

Krispy

Well-Known Member

I was going to ask the same question Krispy haha

You know why I am asking

OOPS. Did I send you a 717 manifold? If so I'll make it right just hit me up.

Shoot sorry about that brother. A correct fitting minty Watercraft magic billet manifold is on it's way priority. I haven't made a newb mistake like that in a hot minute, sorry to slow your progress.

glsmohio

Well-Known Member

OOPS. Did I send you a 717 manifold? If so I'll make it right just hit me up.

thanks matt for working with me. not a problem at all. I think ill like this even better.

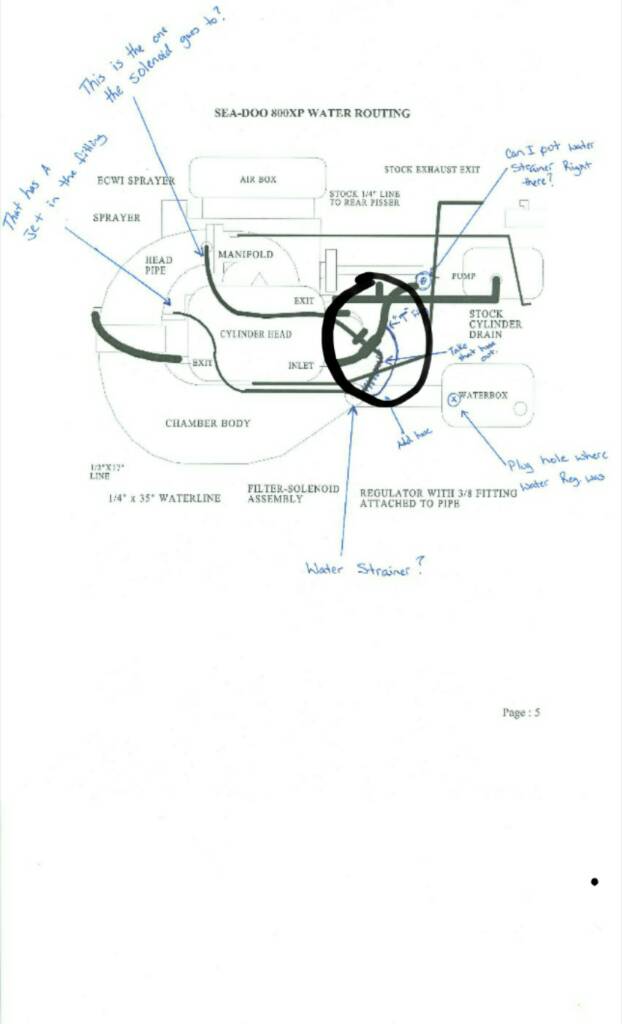

so i did a little drawing on the fp water routeing....Please take a look and tell me if this looks right. I have some big $$ in my blue hose and done want to mess up.

glsmohio

Well-Known Member

glsmohio

Well-Known Member

Get with Braley

thanks man, i think we are both on the same page, i did say something to him, hes going to look at what i posted but i think me and you are on the same page...

fitty650sx

Active Member

Run the water just like the FPP instructions for the Spec 2. You don't have the FPP strainer so you'll have to figure something out there, but It's not difficult

glsmohio

Well-Known Member

Run the water just like the FPP instructions for the Spec 2. You don't have the FPP strainer so you'll have to figure something out there, but It's not difficult

i have a spec1

I think i got it just wanted someone to look at my notes and see if im right...i got $50 plus just in the blue hose and can only cut once lol

fitty650sx

Active Member

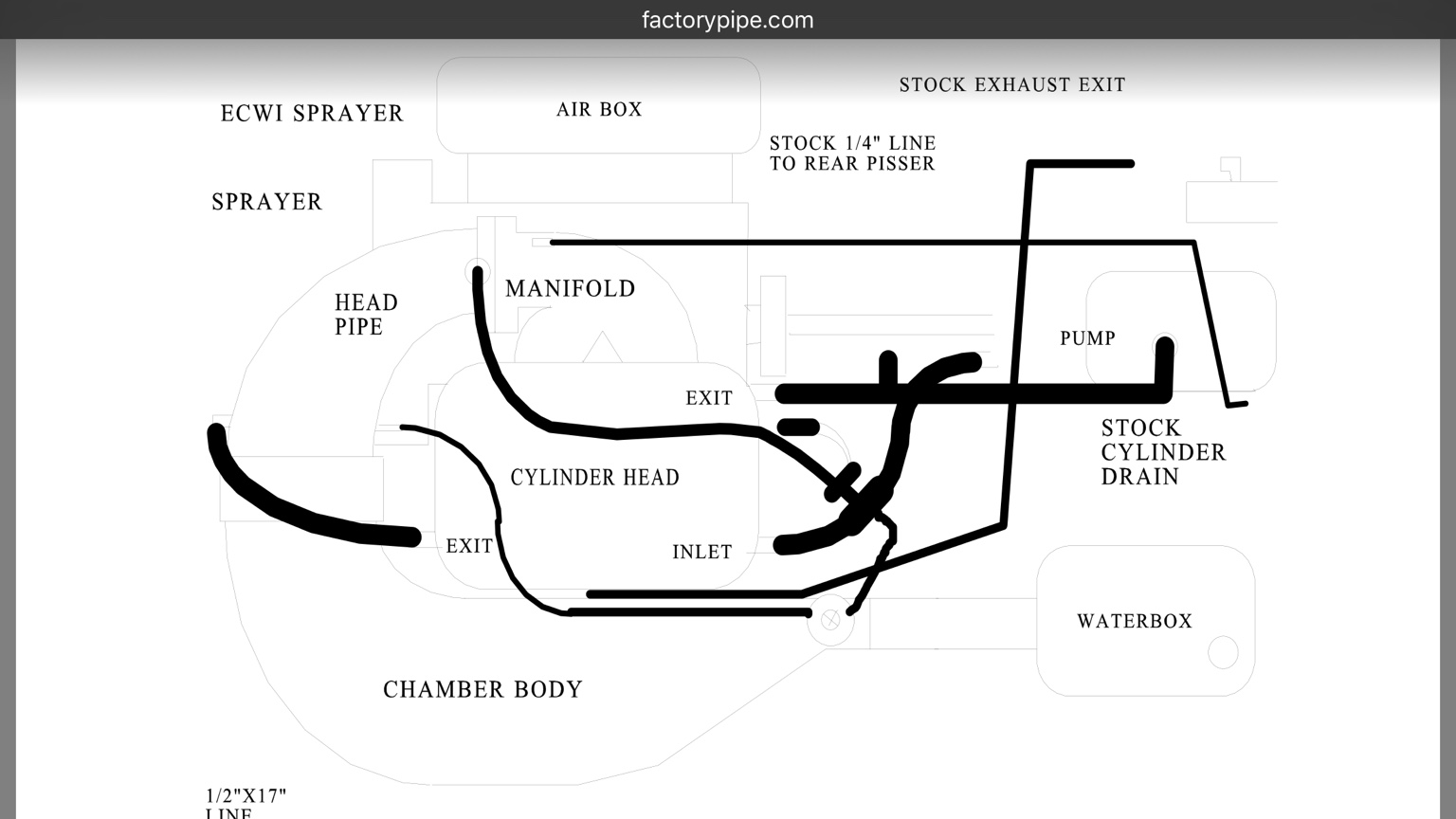

This is how I hard jetted my Spec2 on my GSX. Took me a while to dig for these pictures.

If you're keeping the water regulator on the waterbox, hook it up like you would 'stock'. You can see what we mean by having to 'figure out' how to make your strainer work. This is the FPP strainer.

The black waterline at the top of the pipe goes to the rear 'pisser' just like stock.

This is the spraybar that gets connected to where the water regulator (rave) is/was. This is on the backside of the pipe, which is recommended by FPP for the GSX. The recommended position is in the 'front' position (pointing at the fuel tank), or to the right in this picture.

If you're keeping the water regulator on the waterbox, hook it up like you would 'stock'. You can see what we mean by having to 'figure out' how to make your strainer work. This is the FPP strainer.

The black waterline at the top of the pipe goes to the rear 'pisser' just like stock.

This is the spraybar that gets connected to where the water regulator (rave) is/was. This is on the backside of the pipe, which is recommended by FPP for the GSX. The recommended position is in the 'front' position (pointing at the fuel tank), or to the right in this picture.

From the pump to the strainer then a 1/2" X 1/2" X 3/8" T that feeds the line going to the water injection solenoid. Then a 1/2" X 1/2" X 1/4" T to a 1/4" X 1/4" X 1/4" T. You will have two open barbed 1/4" fittings left. One goes to your stinger (must be jetted) and one to your constant flow on the pipe chamber (also jetted).

This way could be done with your strainer as it is. The 1/2" hose coming out of the front left of the head connects to the 1/2" fitting on the pipe. The rear right 1/2" head fitting dumps out of the hull above the pump. The 1/4" bleeder fitting highest on the pipe feeds the rear indicator(pisser) at the rear U-bolt.

This way could be done with your strainer as it is. The 1/2" hose coming out of the front left of the head connects to the 1/2" fitting on the pipe. The rear right 1/2" head fitting dumps out of the hull above the pump. The 1/4" bleeder fitting highest on the pipe feeds the rear indicator(pisser) at the rear U-bolt.

I typically like to put a 1/2" tee in the line going from the head to the pipe and piss it out of a 5/16" line up front so I can see the cooling system is working properly. If the lower pipe has a stinger in it I delete the water fitting in the waterbox and jet the stinger accordingly to keep the hoses cool (well not really b/c the silicone hose kits can handle it)

glsmohio

Well-Known Member

I don't have a stinger so I'm thinking I should hard jet the water box....?I typically like to put a 1/2" tee in the line going from the head to the pipe and piss it out of a 5/16" line up front so I can see the cooling system is working properly. If the lower pipe has a stinger in it I delete the water fitting in the waterbox and jet the stinger accordingly to keep the hoses cool (well not really b/c the silicone hose kits can handle it)

Yeah I like a 140ish HS main jet in the Waterbox.

glsmohio

Well-Known Member

thanks guys for all the help, i think i got it. just need to pick me up some fittings. I work late tonight so more than likely i wont be able to get to this till thursday night...

On another note, I'm going to have my trim tabs powder coated (only $20 for a set, didnt think that was bad) along with my two r & D nozzles.

also just thinking out loud but on the bracket for the pipe i need to make, i think i might make it out of steel so i can welt it, then just powder coat it or i could do the aluminum and make it shine...thoughts? only bad part is if i do it out of aluminum then i have a $15 weld bill.....

On another note, I'm going to have my trim tabs powder coated (only $20 for a set, didnt think that was bad) along with my two r & D nozzles.

also just thinking out loud but on the bracket for the pipe i need to make, i think i might make it out of steel so i can welt it, then just powder coat it or i could do the aluminum and make it shine...thoughts? only bad part is if i do it out of aluminum then i have a $15 weld bill.....

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 184