I bought a 97 XP yesterday with a trailer and cover.

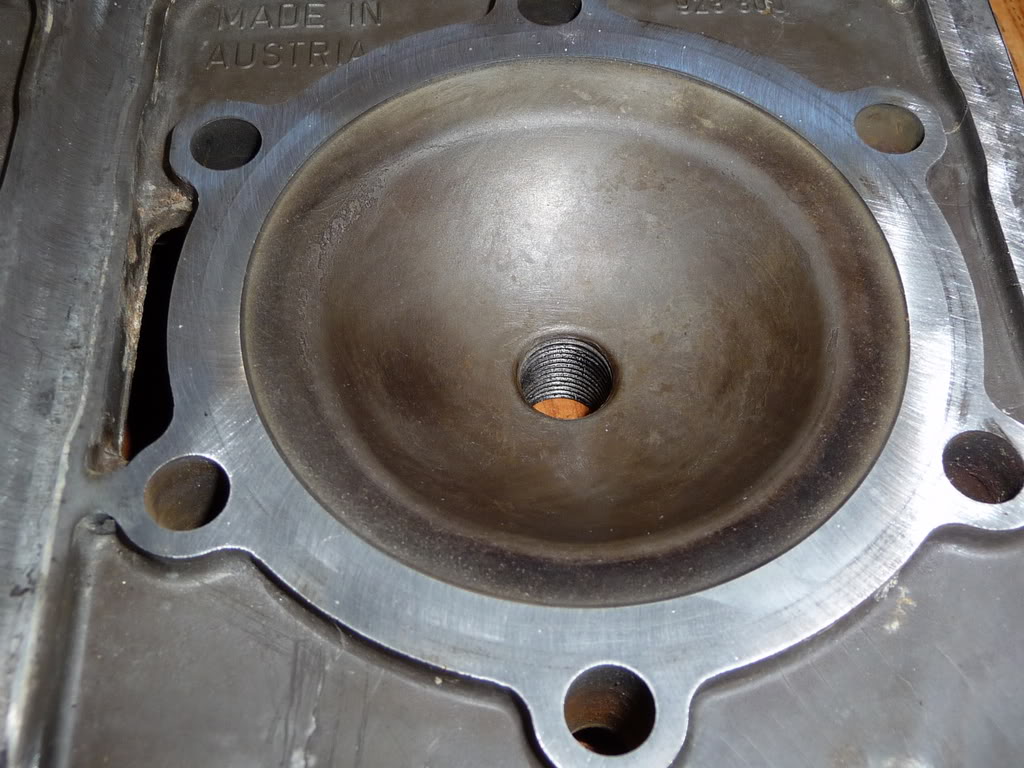

Before a paid the guy, I tried to start it. When you insert the key it beeps two times and attempts to crank but will not start. I figured his battery was low so I connected jumper cables to my truck and it still would not crank. When I removed the plugs, it will crack very fast. The compression in each cylinder is 210 so I figured the engine was good and paid $1000.

When I got it home I did some diagnostics.

1. All of the fuses are good.

2. I put in a fully charged battery which was at 12.5 volts.

3. When cranking the engine with the plugs removed, the voltage drops to about 11 volts.

4. When trying to crank with the plugs in, the voltage drops to about 7 volts.

I have tried different batteries with the same results and also cleaned the battery terminals. I am thinking that the starter may be bad.

Any thoughts on what I can check or what you think the problem may be? I don’t want to buy a starter just to find out that is not the problem.

Before a paid the guy, I tried to start it. When you insert the key it beeps two times and attempts to crank but will not start. I figured his battery was low so I connected jumper cables to my truck and it still would not crank. When I removed the plugs, it will crack very fast. The compression in each cylinder is 210 so I figured the engine was good and paid $1000.

When I got it home I did some diagnostics.

1. All of the fuses are good.

2. I put in a fully charged battery which was at 12.5 volts.

3. When cranking the engine with the plugs removed, the voltage drops to about 11 volts.

4. When trying to crank with the plugs in, the voltage drops to about 7 volts.

I have tried different batteries with the same results and also cleaned the battery terminals. I am thinking that the starter may be bad.

Any thoughts on what I can check or what you think the problem may be? I don’t want to buy a starter just to find out that is not the problem.