-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My new 96 XP project

- Thread starter Major Woody

- Start date

- Status

- Not open for further replies.

The back pressure I was measuring was a 951 DI that injects the oil on the opposite side of the engine from the intake. I was just mentioning that. Not sure if that is relevant at all to the 787. I primed a few 787s and 717s the oil just seems to drip out into the intake I have one I can check for you if need be. I got engines all over the place. LOL Good Luck !

Major Woody

Active Member

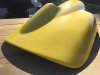

During the evenings last week I repaired a few chips in the gelcoat on the upper hull, and proceeded with color sanding. When they painted the graphics on the ski, they used a razor blade on the hull to trim the masking tape so there were lots of scratches to sand out. Went after them with 400 and then sanded the whole upper hull with 600 and finally 1200.

The Blowsion decal and the style of the old graphics are the reason I think this had a vintage Dady paint job on it. Shame it could not be kept.

Saturday I had most of the day to work on the ski. I finished color sanding it and then got after it with the buffer. It looks really good, and the yellow is very forgiving. If it was black, I'd still be sanding. Today I got the DESS post, MPEM and keys back from Westside, finished up the VTS relay (moved all VTS controls up to gray electrical box) and installed box and wiring.

Oil pump showed up as well. After a trip through the parts washer, I hooked the pump up to the tank and RV cover on my workbench and tested it using the drill in reverse. The oil moves as it should, so now will leave it overnight and see if the injectors seep. If they do, I'll have to order new ones. If not, will reassemble.

Last week I was removing the oil pump block off plate and one of the allen head cap screws just wouldn't budge so I figured the best way to attack it would be to just pull the whole stator cover and take it to the drill press and drill the head off the screw. Underneath that cover was quite a lot of rust. Looks like the PO had some water in the hull and it either got in through the starter opening or past the O-ring. There was no water but lots of rust to clean up. It's just cosmetic but I'm sure glad I pulled that cover off. That is not an easy area to clean with the engine in.

If anyone wants an old-skool R&D oil pump block off plate, I've got one for cheap.

The Blowsion decal and the style of the old graphics are the reason I think this had a vintage Dady paint job on it. Shame it could not be kept.

Saturday I had most of the day to work on the ski. I finished color sanding it and then got after it with the buffer. It looks really good, and the yellow is very forgiving. If it was black, I'd still be sanding. Today I got the DESS post, MPEM and keys back from Westside, finished up the VTS relay (moved all VTS controls up to gray electrical box) and installed box and wiring.

Oil pump showed up as well. After a trip through the parts washer, I hooked the pump up to the tank and RV cover on my workbench and tested it using the drill in reverse. The oil moves as it should, so now will leave it overnight and see if the injectors seep. If they do, I'll have to order new ones. If not, will reassemble.

Last week I was removing the oil pump block off plate and one of the allen head cap screws just wouldn't budge so I figured the best way to attack it would be to just pull the whole stator cover and take it to the drill press and drill the head off the screw. Underneath that cover was quite a lot of rust. Looks like the PO had some water in the hull and it either got in through the starter opening or past the O-ring. There was no water but lots of rust to clean up. It's just cosmetic but I'm sure glad I pulled that cover off. That is not an easy area to clean with the engine in.

If anyone wants an old-skool R&D oil pump block off plate, I've got one for cheap.

Last edited:

Major Woody

Active Member

My test rig revealed that the MAG side injector has a slow seep, but that the PTO injector seems to hold. Removed the leaking one and ordered a new one. Glad I did that.

Last week I was removing the oil pump block off plate and one of the allen head cap screws just wouldn't budge so I figured the best way to attack it would be to just pull the whole stator cover and take it to the drill press and drill the head off the screw. Underneath that cover was quite a lot of rust. Looks like the PO had some water in the hull and it either got in through the starter opening or past the O-ring. There was no water but lots of rust to clean up. It's just cosmetic but I'm sure glad I pulled that cover off. That is not an easy area to clean with the engine in.

I pull the mag cover on every engine. The second ski I bought had issues in there so I suspect all of them and as you say it is a pain to get in there when it is in the ski but... I"ve done that a few times as well. This we my first one and it was so dirty and corroded I cleaned up real good and used Glyptal. Good stuff.

My ski would start when it wanted but mostly wouldn't start. No fire. The pick up magnet was coated with old metal and rust. Every now and they it would start. Good Luck with yours !!!

Major Woody

Active Member

Thanks man. I really dig this ski. Sometimes I just go out and stare at it, which is weird.You got that thing looking GREAT !!

I really dig this ski. Sometimes I just go out and stare at it, which is weird.

Naw I understand. There are others too.

Major Woody

Active Member

Replaced the PTO side oil injector, installed RV cover, carbs, oil pump and lines, reinstalled gas and oil tanks, sync'd the carbs and adjusted the oil pump. PO had cut the fuel return line too short when replacing, so I had to get a new length of hose which was expensive (I only use the fuel injection rated hose). Installed pipe and torqued everything.

Everything looks really good. I wish SBT had done a better job painting the longblock. There is some blistering of the paint which I will address down the road when it gets rebuilt next time. I didn't want to pull the engine just to paint it.

Left to do:

1--lift ski, turn onto side, repair gelcoat damage on bottom half of hull and colorsand/buff

2--reinstall rub rails/bumper and grab handle

3--finish painting/assembling single gauge hood, and install.

4--mats

5--install battery and VTS motor and connect wires

6--bleed oil injection system

7--try to start, take to ramp and set idle in water. Hopefully it goes BRAAAAAAP!

Everything looks really good. I wish SBT had done a better job painting the longblock. There is some blistering of the paint which I will address down the road when it gets rebuilt next time. I didn't want to pull the engine just to paint it.

Left to do:

1--lift ski, turn onto side, repair gelcoat damage on bottom half of hull and colorsand/buff

2--reinstall rub rails/bumper and grab handle

3--finish painting/assembling single gauge hood, and install.

4--mats

5--install battery and VTS motor and connect wires

6--bleed oil injection system

7--try to start, take to ramp and set idle in water. Hopefully it goes BRAAAAAAP!

Major Woody

Active Member

Used the lifting hoist and straps to flip the ski. Rear rests on a sawhorse and front rests on plank and cinder blocks. Now I can see what I'm dealing with.

There is a spot of damage just ahead of the port side trim tab where it looks like someone hit something very hard at high speed. Big gouge in the hull and a good size gouge in the trim tab as well. That must have been exciting.

Application of stripper to the white crap suggested it really was brush-on gelcoat of some sort because the stripper only softened it slightly, even sitting for 30 hours. I scraped it off and found that the PO had sanded the gelcoat completely away to get rid of the damage, before brushing the stuff on. So spot repairs aren't going to work--not in the center between the strakes, anyway. I will finish the repairs and then spray on new gelcoat there. Elsewhere there are some isolated gouges that I can fix with the paste type gelcoat repair kit I have.

I ordered a RAL color chart on Amazon so I can find the closest color number to the gelcoat that's on there. In my opinion the closest color is RAL 1018. FibreGlast.com is the only place I have been able to find online who will mix custom tinted gelcoat if you give them a RAL color number to go off of.

I'll document the gelcoat repair process in future posts. I do have a gun with a 3.0 tip. I will not be rolling it on; spraying provides a better build, wastes far less material and levels out much better. Beyond that, I would appreciate any tips from anyone who has done this before.

There is a spot of damage just ahead of the port side trim tab where it looks like someone hit something very hard at high speed. Big gouge in the hull and a good size gouge in the trim tab as well. That must have been exciting.

Application of stripper to the white crap suggested it really was brush-on gelcoat of some sort because the stripper only softened it slightly, even sitting for 30 hours. I scraped it off and found that the PO had sanded the gelcoat completely away to get rid of the damage, before brushing the stuff on. So spot repairs aren't going to work--not in the center between the strakes, anyway. I will finish the repairs and then spray on new gelcoat there. Elsewhere there are some isolated gouges that I can fix with the paste type gelcoat repair kit I have.

I ordered a RAL color chart on Amazon so I can find the closest color number to the gelcoat that's on there. In my opinion the closest color is RAL 1018. FibreGlast.com is the only place I have been able to find online who will mix custom tinted gelcoat if you give them a RAL color number to go off of.

I'll document the gelcoat repair process in future posts. I do have a gun with a 3.0 tip. I will not be rolling it on; spraying provides a better build, wastes far less material and levels out much better. Beyond that, I would appreciate any tips from anyone who has done this before.

Last edited:

I'm not a glass guy at all so I'm very impressed that hulls like this can and are getting saved. It's expensive for me to hire local shops to fix hulls like that and the work is not up to the standards that I've seen on some of the projects on this forum.

Major Woody

Active Member

Fuel and oil tanks are dry, otherwise there would be a huge mess. I had previously removed everything from the hull except the long block so when I put the tanks and everything back, I just left them dry because I knew this thing was gonna have to be upside down to fix the hack work on the bottom.

When I built this shop, I set a 10" tall I-beam on the wall's top plates, recessed into the ceiling. A beam trolley rides on it, with a chain hoist hanging from that. The capacity is 2T. I have 9' ceilings like most garages. Sorry for the sideways picture.

I clipped a carabiner to the chain hoist and looped a pair of lifting straps around the ski and clipped them to the carabiner. Using that, I am able to lift the ski off the trailer and do whatever I want with it.

Once it is in the air, I was able to slide it in the loops until it was on its side.

Lowered it onto moving blankets and tipped it further.

Then lifted it back up to clear the handlebars and finished rolling it. Then I set the back down on a sawhorse...

and the front onto a chunk of wood and cinder blocks (the hood is off, providing a flat surface to rest it on).

It looks like the handlebars are on the floor but there is actually an inch or so of daylight underneath them.

If this ski was a big four stroke, I don't think I would attempt it with the engine in. Just too heavy and too hard to manage. But an empty XP is very light. I was able to do it solo, barely. With three more hands, it would have been quite easy.

Here is the gelcoat kit I used to deal with the chips and the gouges. $30. It is a paste and comes with tubes of colorant to tint it to match. Because it is a paste, it is not usable for recoating large areas.

You just mask off the hull around the gouged area, mix the gelcoat and tint, catalyze it, smooth it into the low spots, cover with a thin film of plastic to aid in smoothing it flat, and use a spreader to level it. Then the next day remove the plastic film and the masking and the patched area will be slightly proud of the gelcoat around it. Then you use a block and wet-sand it flush.

Despite using quite a lot of colorant, the patches are not fully opaque. But for the bottom of the ski, it's fine.

My next posts will show the patches sanded flat as I prepare to spray new gelcoat on the center section.

When I built this shop, I set a 10" tall I-beam on the wall's top plates, recessed into the ceiling. A beam trolley rides on it, with a chain hoist hanging from that. The capacity is 2T. I have 9' ceilings like most garages. Sorry for the sideways picture.

I clipped a carabiner to the chain hoist and looped a pair of lifting straps around the ski and clipped them to the carabiner. Using that, I am able to lift the ski off the trailer and do whatever I want with it.

Once it is in the air, I was able to slide it in the loops until it was on its side.

Lowered it onto moving blankets and tipped it further.

Then lifted it back up to clear the handlebars and finished rolling it. Then I set the back down on a sawhorse...

and the front onto a chunk of wood and cinder blocks (the hood is off, providing a flat surface to rest it on).

It looks like the handlebars are on the floor but there is actually an inch or so of daylight underneath them.

If this ski was a big four stroke, I don't think I would attempt it with the engine in. Just too heavy and too hard to manage. But an empty XP is very light. I was able to do it solo, barely. With three more hands, it would have been quite easy.

Here is the gelcoat kit I used to deal with the chips and the gouges. $30. It is a paste and comes with tubes of colorant to tint it to match. Because it is a paste, it is not usable for recoating large areas.

You just mask off the hull around the gouged area, mix the gelcoat and tint, catalyze it, smooth it into the low spots, cover with a thin film of plastic to aid in smoothing it flat, and use a spreader to level it. Then the next day remove the plastic film and the masking and the patched area will be slightly proud of the gelcoat around it. Then you use a block and wet-sand it flush.

Despite using quite a lot of colorant, the patches are not fully opaque. But for the bottom of the ski, it's fine.

My next posts will show the patches sanded flat as I prepare to spray new gelcoat on the center section.

Major Woody

Active Member

A little bit more about the work on the seat. The seat on this was not terrible when I got it, but had damage. At the center front, the vinyl had either torn or shrunken back to where the foam was exposed. The sun had hardened the foam and the area around it was raised and crusty. The plastic corner covers were MIA. There were a couple small tears in the cover. On my GSX, the seat cover and the foam are fused together so your only real option is to glue a new cover to the old one. On an XP, the cover is not glued to the foam so you can remove it entirely and reshape the seat if you want to.

Once I had taken the old cover off, it was obvious the cover had a significant "dip" where the strap was, plus the damage at the front where the sun attacked it, plus a tear in the foam on the right side. Additionally, the little corner protectors don't match the new seat cover so I wanted to clean up and reshape that area and get rid of the protectors. I used a DA sander and an air file aka "jitterbug" sander to flatten the foam. This completely eliminated the dip where the strap was, and re-shaped the crusty area at the front of the seat. Believe it or not you can sand this foam if you use a coarse enough grit and the right sander. In the photo, you can see the shadow of where the strap was, but the dip is gone.

Next, I used ProPoxy 20 epoxy putty to reshape the plastic seat frame where the strap is and where the corner covers are. Sanded that smooth to match the existing contours of the seat.

Finally I used Dynaflex 230 caulk and a bondo spreader to re-contour the foam and repair the rip in it. Multiple thin layers are key. This is the last step, as you cannot sand caulk. The caulk is firmer than the foam itself, so I would be reluctant to use it in the main part of the seat. For major damage, it would be better to find a better seat and start with that.

Above is a photo where I had started to apply caulk and then realized I had more sanding to do. I had gotten ahead of myself and had to peel some away. I don't have any photos of the final layer of caulk but it ended up being super smooth. I used it to smooth out the sun-damaged foam at the front edge of the seat.

This picture shows the side where the foam was ripped. Fill rip with caulk, use masking tape to hold it shut while the caulk cures, then a thin skim to smooth out the repair...invisible.

Anyway I am pleased with the way the foam and seat frame turned out. The seat cover lays smoothly over it, doesn't dip in where the front corners are or where the strap was, and there is a smooth transition where the foam meets the rounded plastic frame.

The end product:

and yes, I used stainless staples.

Not too shabby for a $66 Black Friday cover!

Once I had taken the old cover off, it was obvious the cover had a significant "dip" where the strap was, plus the damage at the front where the sun attacked it, plus a tear in the foam on the right side. Additionally, the little corner protectors don't match the new seat cover so I wanted to clean up and reshape that area and get rid of the protectors. I used a DA sander and an air file aka "jitterbug" sander to flatten the foam. This completely eliminated the dip where the strap was, and re-shaped the crusty area at the front of the seat. Believe it or not you can sand this foam if you use a coarse enough grit and the right sander. In the photo, you can see the shadow of where the strap was, but the dip is gone.

Next, I used ProPoxy 20 epoxy putty to reshape the plastic seat frame where the strap is and where the corner covers are. Sanded that smooth to match the existing contours of the seat.

Finally I used Dynaflex 230 caulk and a bondo spreader to re-contour the foam and repair the rip in it. Multiple thin layers are key. This is the last step, as you cannot sand caulk. The caulk is firmer than the foam itself, so I would be reluctant to use it in the main part of the seat. For major damage, it would be better to find a better seat and start with that.

Above is a photo where I had started to apply caulk and then realized I had more sanding to do. I had gotten ahead of myself and had to peel some away. I don't have any photos of the final layer of caulk but it ended up being super smooth. I used it to smooth out the sun-damaged foam at the front edge of the seat.

This picture shows the side where the foam was ripped. Fill rip with caulk, use masking tape to hold it shut while the caulk cures, then a thin skim to smooth out the repair...invisible.

Anyway I am pleased with the way the foam and seat frame turned out. The seat cover lays smoothly over it, doesn't dip in where the front corners are or where the strap was, and there is a smooth transition where the foam meets the rounded plastic frame.

The end product:

and yes, I used stainless staples.

Not too shabby for a $66 Black Friday cover!

Last edited:

Major Woody

Active Member

I hope you put plastic over the foam before the seat cover?A little bit more about the work on the seat. The seat on this was not terrible when I got it, but had damage. At the center front, the vinyl had either torn or shrunken back to where the foam was exposed. The sun had hardened the foam and the area around it was raised and crusty. The plastic corner covers were MIA. There were a couple small tears in the cover. On my GSX, the seat cover and the foam are fused together so your only real option is to glue a new cover to the old one. On an XP, the cover is not glued to the foam so you can remove it entirely and reshape the seat if you want to.

Once I had taken the old cover off, it was obvious the cover had a significant "dip" where the strap was, plus the damage at the front where the sun attacked it, plus a tear in the foam on the right side. Additionally, the little corner protectors don't match the new seat cover so I wanted to clean up and reshape that area and get rid of the protectors. I used a DA sander and an air file aka "jitterbug" sander to flatten the foam. This completely eliminated the dip where the strap was, and re-shaped the crusty area at the front of the seat. Believe it or not you can sand this foam if you use a coarse enough grit and the right sander. In the photo, you can see the shadow of where the strap was, but the dip is gone.

View attachment 46416

Next, I used ProPoxy 20 epoxy putty to reshape the plastic seat frame where the strap is and where the corner covers are. Sanded that smooth to match the existing contours of the seat.

View attachment 46410

View attachment 46411

Finally I used Dynaflex 230 caulk and a bondo spreader to re-contour the foam and repair the rip in it. Multiple thin layers are key. This is the last step, as you cannot sand caulk. The caulk is firmer than the foam itself, so I would be reluctant to use it in the main part of the seat. For major damage, it would be better to find a better seat and start with that.

View attachment 46417

Above is a photo where I had started to apply caulk and then realized I had more sanding to do. I had gotten ahead of myself and had to peel some away. I don't have any photos of the final layer of caulk but it ended up being super smooth. I used it to smooth out the sun-damaged foam at the front edge of the seat.

This picture shows the side where the foam was ripped. Fill rip with caulk, use masking tape to hold it shut while the caulk cures, then a thin skim to smooth out the repair...invisible.

View attachment 46414

Anyway I am pleased with the way the foam and seat frame turned out. The seat cover lays smoothly over it, doesn't dip in where the front corners are or where the strap was, and there is a smooth transition where the foam meets the rounded plastic frame.

The end product:

View attachment 46412

View attachment 46413

and yes, I used stainless staples.

Not too shabby for a $66 Black Friday cover!

If you didn't the foam will absorb water through the stitching on the cover and begin to soak up water and get really heavy.

Pwnage1337

Active Member

Awesome work!!

dr00andrew

Well-Known Member

Will be following along looks like a cool project

Major Woody

Active Member

I hope you put plastic over the foam before the seat cover?

I used paint-on seam sealer on the stitching, like what you use to seal the seams of a tent. This ski will not be stored outdoors. It has seen enough weather for one lifetime.

Thanks everyone for the compliments, suggestions and encouragement. I find it very motivating.

Last edited:

That should work fine. It's not just for sitting outside though. When riding and splashing around they can soak up a lot of water.I used paint-on seam sealer on the stitching, like what you use to seal the seams of a tent. This ski will not be stored outdoors. It has seen enough weather for one lifetime.

Thanks everyone for the compliments, suggestions and encouragement. I find it very motivating.

Major Woody

Active Member

Working on polishing the bottom and was fitting up the UMI grate that came on the ski. Noticed that the grate is broken around the forward bolt holes. One side is cracked completely through and the other side is cracked in a vee with a loose piece. It could be welded, at a price (I can't TIG weld).

Welding it will likely cost as much as it would cost to replace it. Anyone have a suitable grate as a replacement? Interested in hole shot vs top end; we ride quite a lot in chop and play a lot so I am most interested in strong hookup from a standing stop. TIA

Welding it will likely cost as much as it would cost to replace it. Anyone have a suitable grate as a replacement? Interested in hole shot vs top end; we ride quite a lot in chop and play a lot so I am most interested in strong hookup from a standing stop. TIA

No intake grate is going to give you hookup from a standing stop because the pump is already in the water.

A scoop grate will help it stay hooked up better in chop and will suck the ski down a little more in the turns so that's the benefit. The downside is that you lose a few mph on top end and the ski is less playful for doing slides and 360's.

On mine I run the stock grate and am perfectly happy with it.

A scoop grate will help it stay hooked up better in chop and will suck the ski down a little more in the turns so that's the benefit. The downside is that you lose a few mph on top end and the ski is less playful for doing slides and 360's.

On mine I run the stock grate and am perfectly happy with it.

Major Woody

Active Member

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 359