Charleston

New Member

Hello friends,

I have finished the rebuild of the magneto housing. I left the part out from before since it looks like it only bypassed the oil pump. I am running premix so no issue. Evapo-rust did a wonderful job on the flywheel. Also took advice to test the magneto on another link. Great news. Both are good.

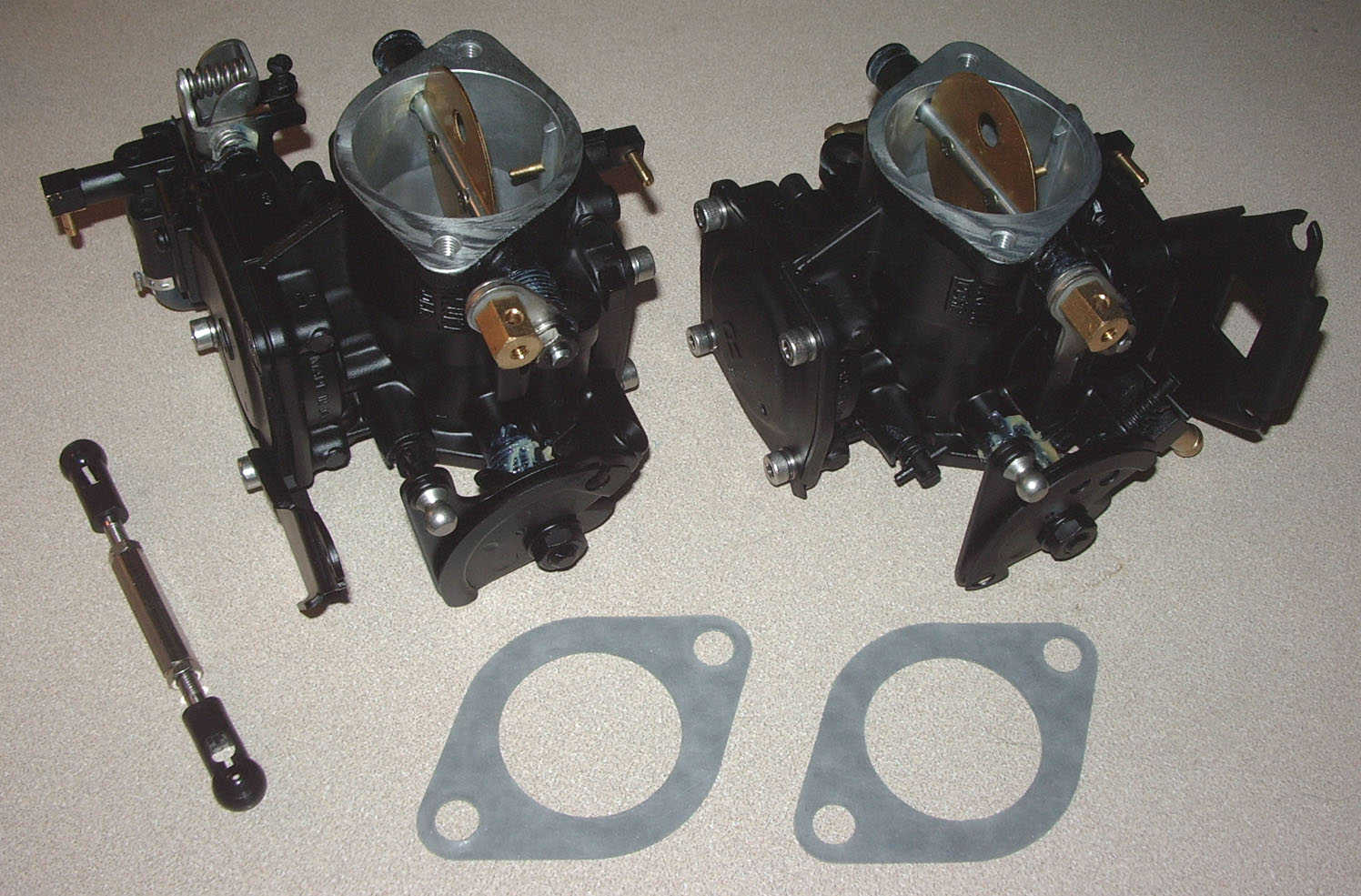

It looks like one of my engine mounts has separated. I was hoping someone here might have seen this before and have a solution. It seems like a small item. Just need to figure out what would bond these two materials back together. Top threaded part is steel and the bottom is a rubber grommet for vibration. See attached.

![IMG_0176[1].jpg IMG_0176[1].jpg](https://www.seadooforum.com/data/attachments/18/18040-cf5b11e6a5f5d97d0247584edf8aa0d4.jpg?hash=z1sR5qX12X)

Thanks again,

Charleston

I have finished the rebuild of the magneto housing. I left the part out from before since it looks like it only bypassed the oil pump. I am running premix so no issue. Evapo-rust did a wonderful job on the flywheel. Also took advice to test the magneto on another link. Great news. Both are good.

It looks like one of my engine mounts has separated. I was hoping someone here might have seen this before and have a solution. It seems like a small item. Just need to figure out what would bond these two materials back together. Top threaded part is steel and the bottom is a rubber grommet for vibration. See attached.

![IMG_0176[1].jpg IMG_0176[1].jpg](https://www.seadooforum.com/data/attachments/18/18040-cf5b11e6a5f5d97d0247584edf8aa0d4.jpg?hash=z1sR5qX12X)

Thanks again,

Charleston