SeaDooGood

New Member

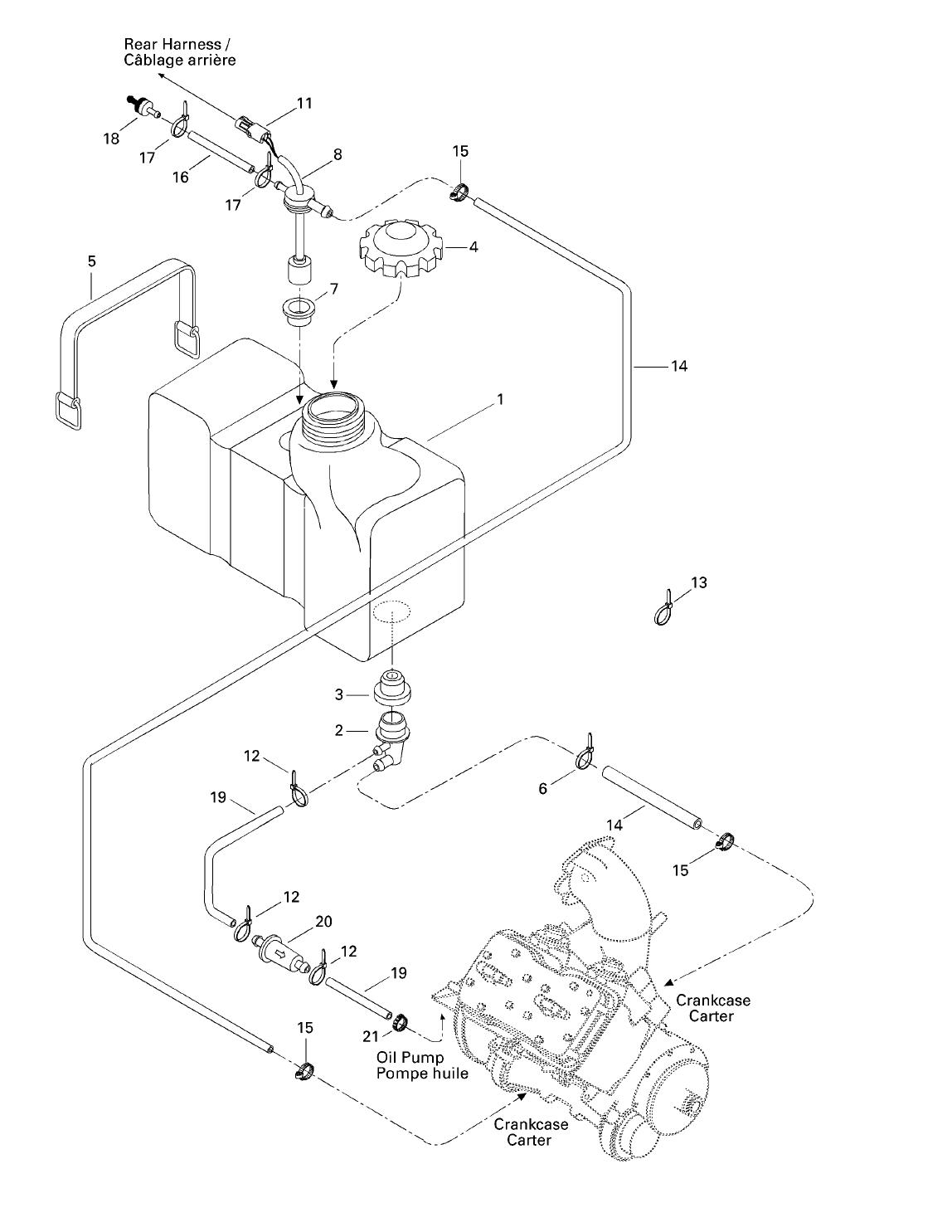

I'm not the most mechanically inclined person to begin with (medical field) and I'm new to the whole Seadoo world. I picked up my first ski recently and I'm trying to become more familiar with it and do a lot of things myself to learn. I've attached a pic of the oil system diagram and was just wondering if someone could exlplain to me how it works. I also want to drain all the oil out and put some good low ash api PWC oil (XPS, Amasoil interceptor, etc...) so knowing how the system works will help. It looks like it has two oil injection hoses, one on the top (#14) coming off the nipple on the oil level sensor assembly (#8) and one below the tank coming off the LOWER nipple on the elbow fitting (#2) attached to the grommet (#3). So, is oil injected into the engine through BOTH of these hoses coming from the TOP and the BOTTOM of the oil tank? I see another hose (#19) coming off the TOP nipple of the elbow fitting (#2) attached to the grommet (#3) and it goes to the oil filter and then comes off the other side of the filter going to the oil pump. Excuse me for asking a dumb question here, but does this hose (#19) pump oil back OUT of the engine, through the filter, and back into the oil tank where it is then injected back into the engine through the hose on the top and bottom (LOWER nipple of elbow fitting)? Sorry, but I'm a bit confused and just trying to learn and understand the system. Lastly, I keep hearing people refer to the "rotary valve." Where is the rotary valve located and what is it's purpose? Thanks in advance for bearing with me!

Attachments

Last edited by a moderator: