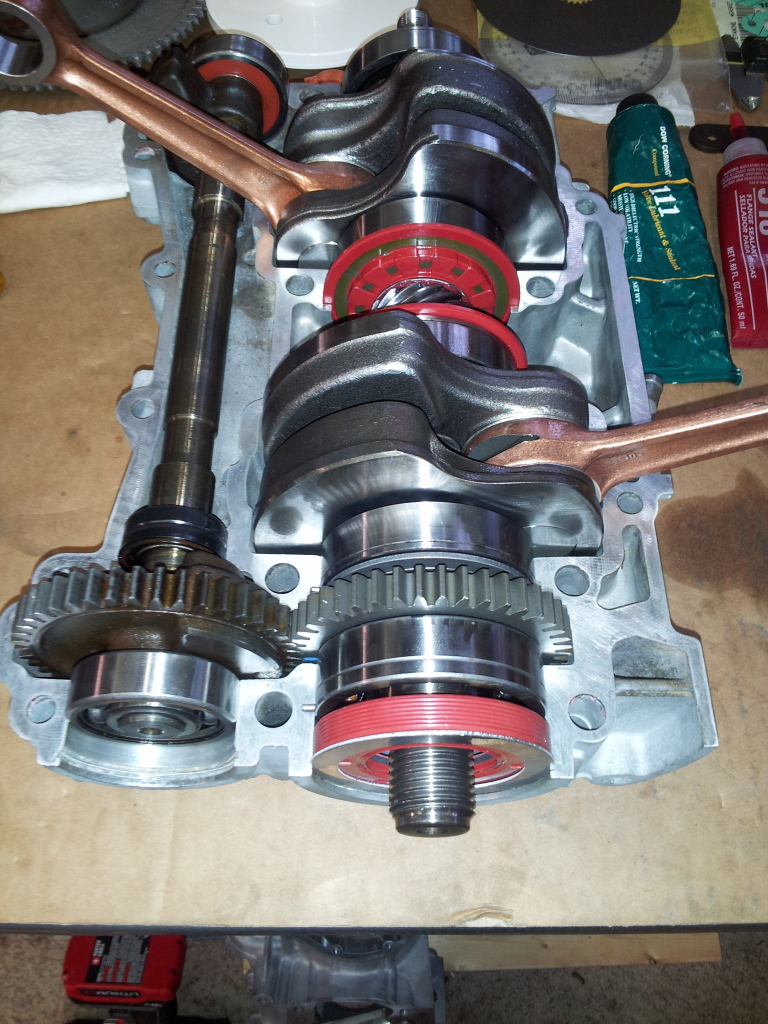

The reman crank has a hash mark with a blue line to highlight it. So I am sure they indexed it. just not in the exact same spot as my original crank. The phasing of the crank between cylinders is dead on, so I am guessing the CB shaft being a few degrees out of phase doesn't cause any imbalance issues.

Seeing it's easy to push the weights off the CB shaft, I might as well rotate them 2 degrees to compensate just because I can & its the middle of winter here.

. Probably completely unnecessary & whoever takes this engine apart in the future will think the CB was assembled wrong as the hash marks I made on the shaft ends will not be lined up anymore. But at least then I know everything is dead on.

The engine has only been assembled to measure things anyway, so its really no big deal to do it. Take way less time than I spend researching things.

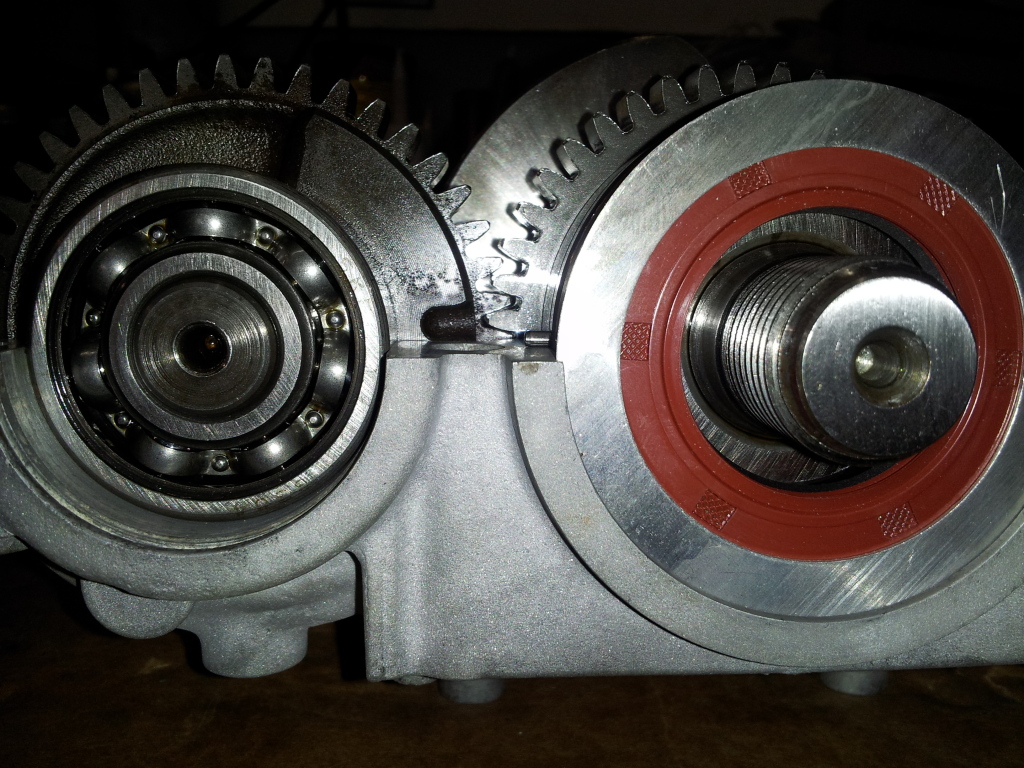

BTW, I also decided to ditch those seals on the replacement CB bearing by the air pump. I couldn't find anything pointing to the original open bearings being know to fail anymore than the sealed ones on the other side. Only thing I could come up with is possible moisture contamination to the bearing caused from compressing air in that cavity? I would rather run something I know has been working for years, rather than something nobody has heard of. I really doubt seadoo cares $.02 about a bearing revision on a 11 year old ski. Probably has more to do with the bearing supplier having sealed bearings as a less expensive replacement......?

For the life of me I couldn't figure out how the injection oil gets returned to the oil tank from a drain in the bottom of the air pump section of the case & has to go uphill to get back to the oil tank. Then I realized the chamber is probably under a little bit of pressure from the air pump blow by? just a guess, not sure on that one......