hotrodssnova

Member

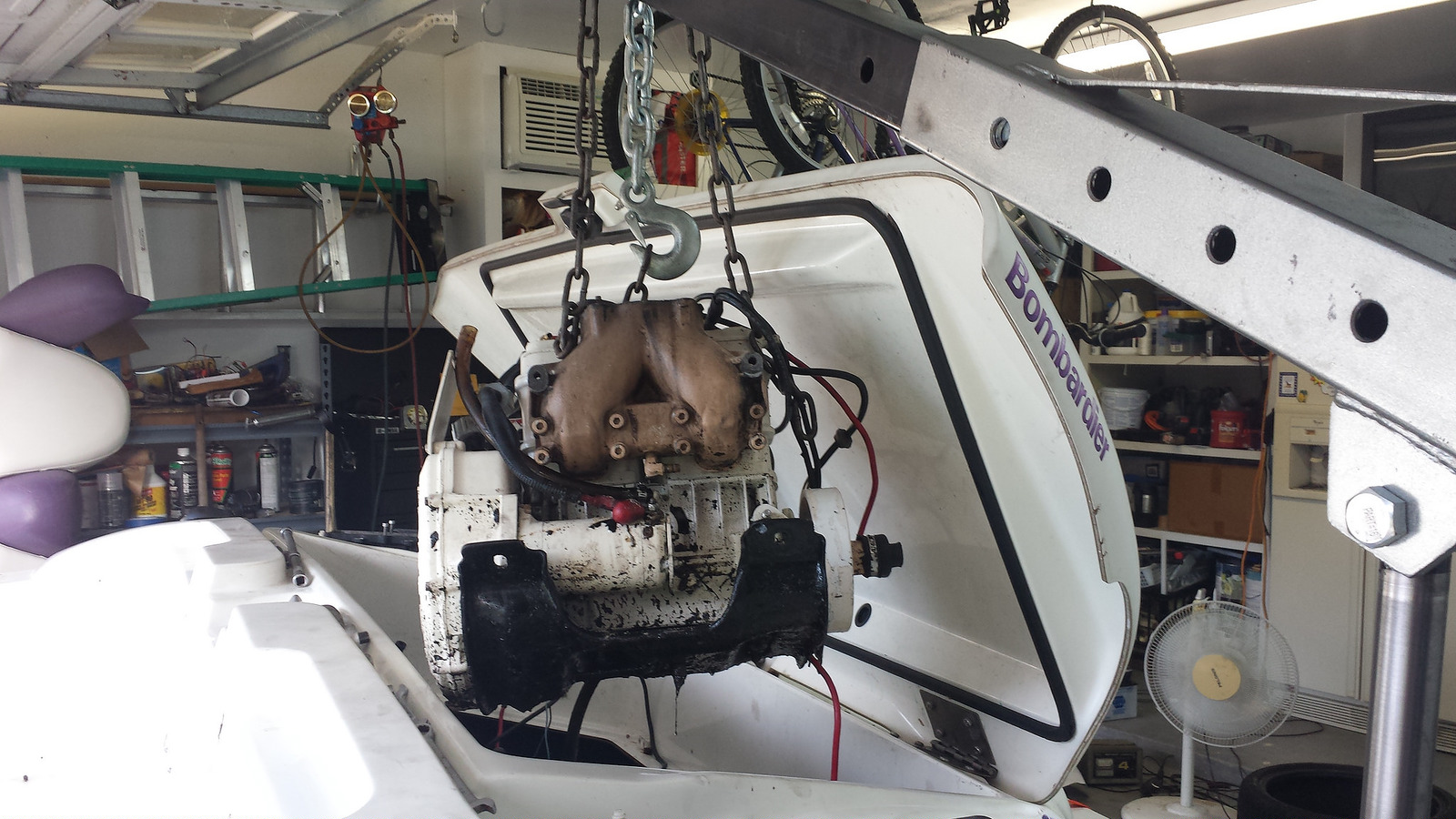

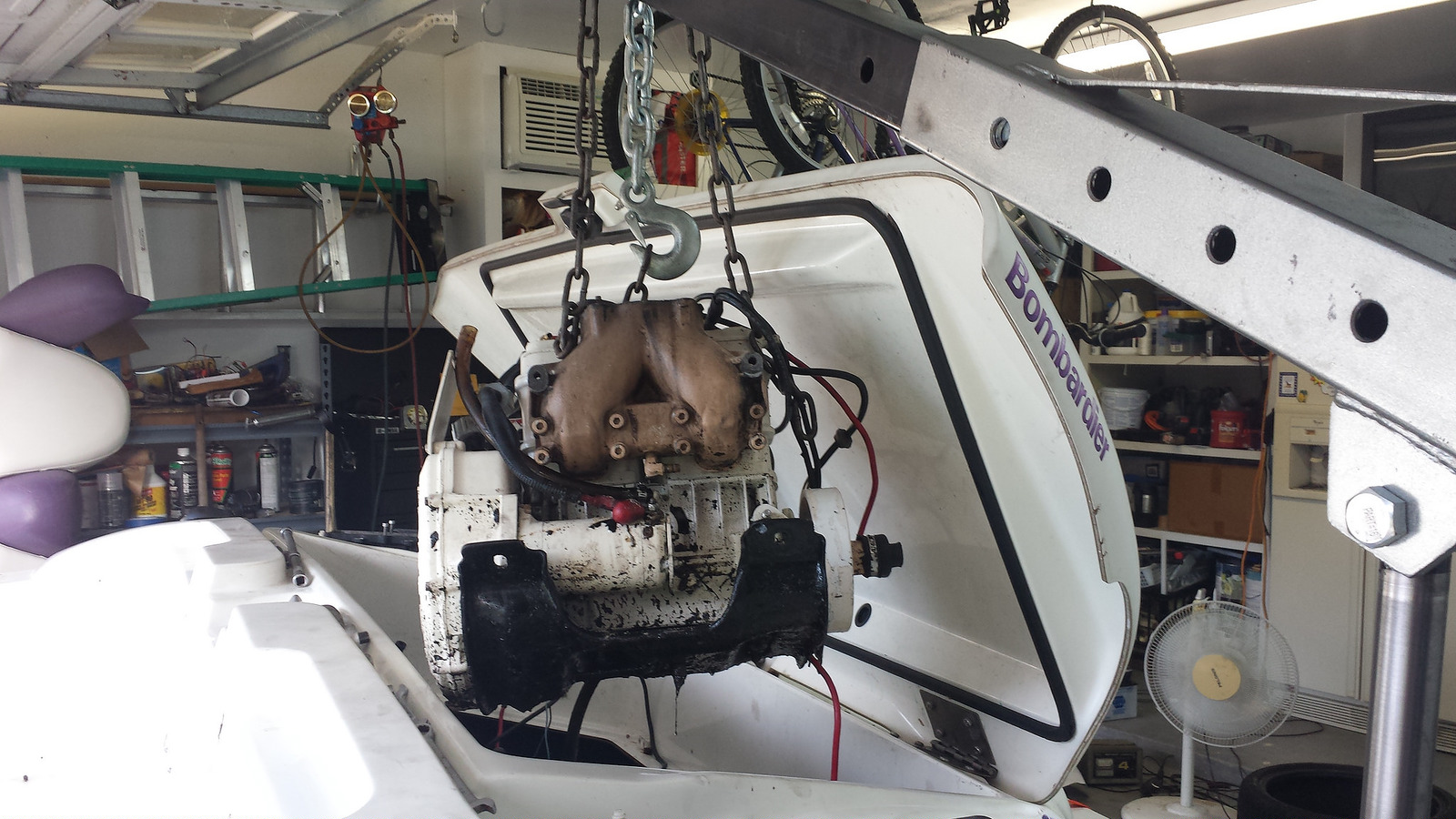

I just went through this with my 94 speedster.

All my wiring was reading shorted to ground.

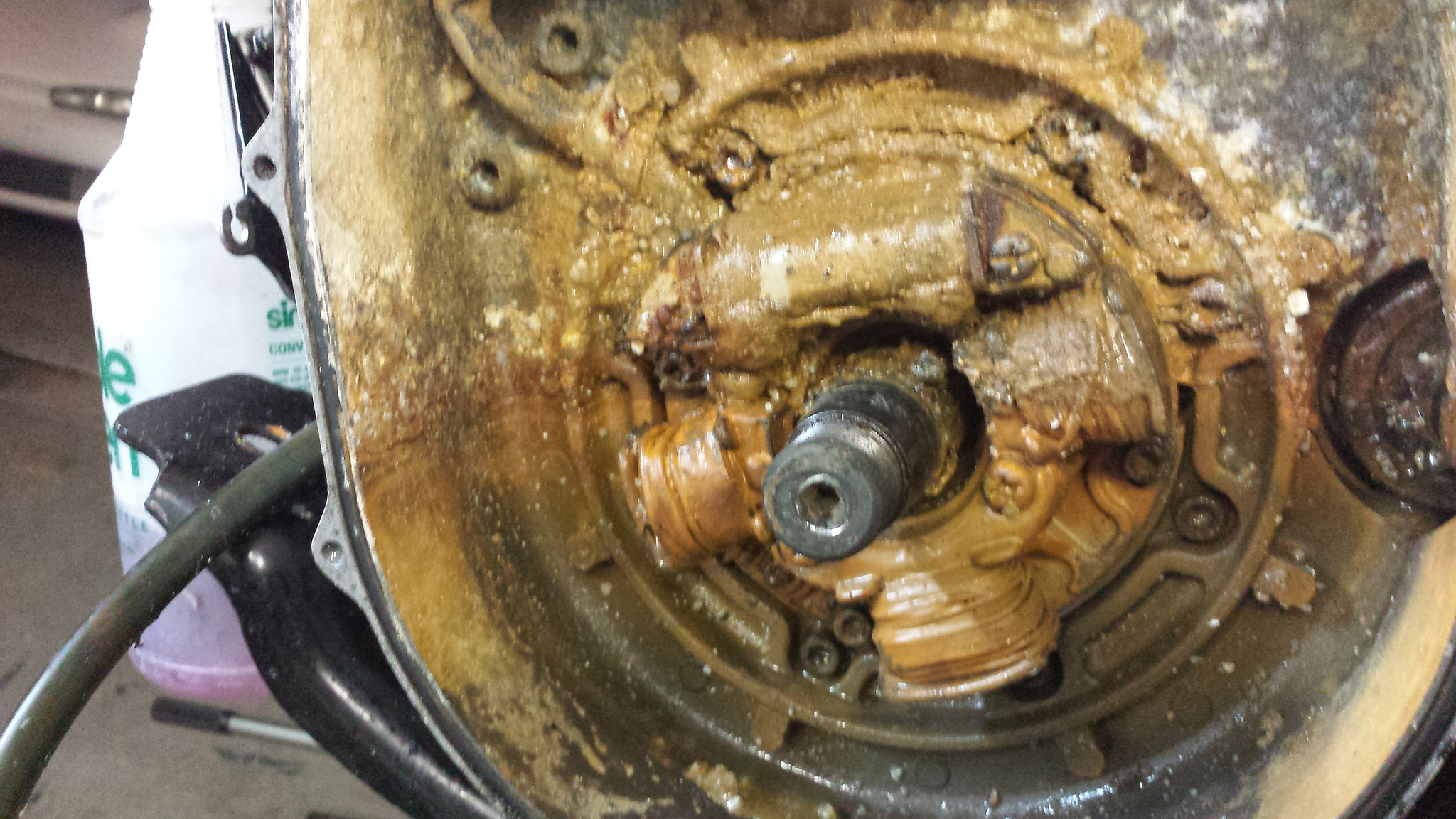

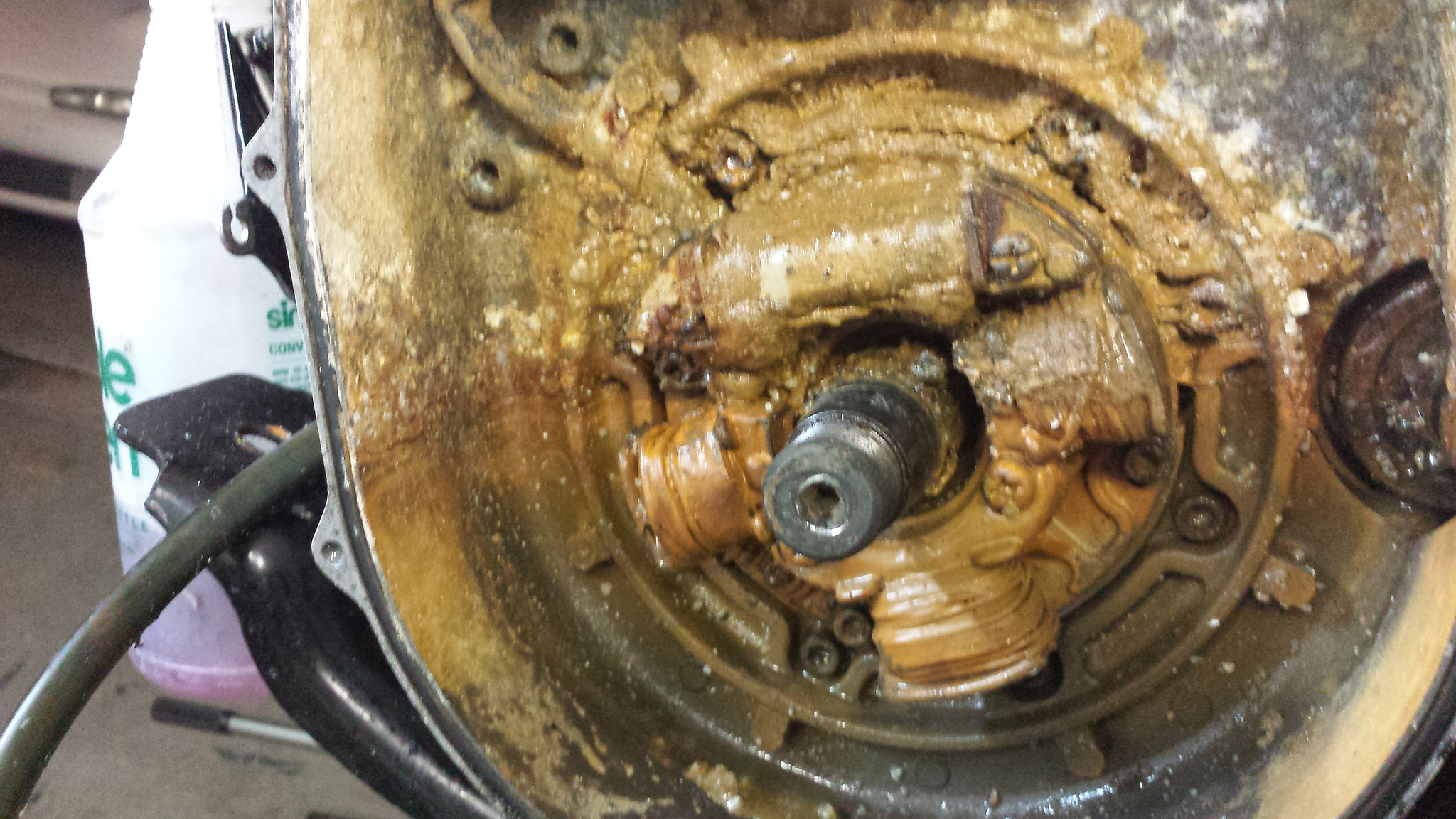

I found this in the mag housing.

I found a loose starter bolt. I concluded that that bolt left a small leak and water had filled the mag housing. From what I can see, the boat sat for about a year. Still working on it now.

All my wiring was reading shorted to ground.

I found this in the mag housing.

I found a loose starter bolt. I concluded that that bolt left a small leak and water had filled the mag housing. From what I can see, the boat sat for about a year. Still working on it now.

Last edited by a moderator: