alexd51

New Member

First of all Thank you guys for all the help in the past couple months since i acquired this boat, or should i say right now this headache .

When i got the boat it was sitting for what the Original owner said a couple of months. Boat started fine but the gas had been sitting in the tank for a while so to not mess up the carbs more than they might be i started both motors but only ran for less than a minute.

When i got the boat and started to work on it, flushed the fuel and oil tank,changed fuel and oil filters . Oil lines fuel sender unit and was working on an oil leak there was on the side of the motor from what looks like a metal seal that is in a real PITA place to fix unless i remove the motor.

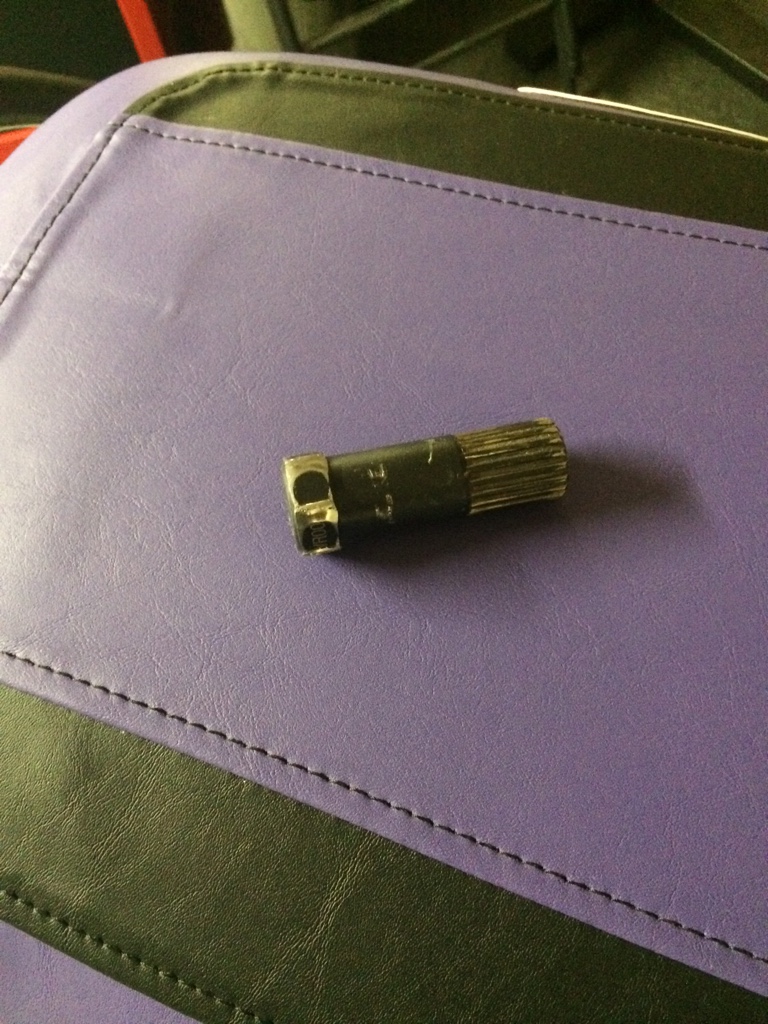

Well while i decided what to do with that seal, either take out the motor or JB weld the hell out of it i decided to take the RAVE valves out because so far all the info the PO has told me is pretty much a bag of lies. Well,Well surprise surprise valves not only look like they have never been taken out but one of them is stuck in there that it will not move only 1/4 inch up and down but not come completely out so my recent post of a stuck valve.

Now thinking of all this i start looking thru all the paperwork i was given when i got the boat receipt for a battery,fuel filter changes and one for the starboard motor being replaced with a SBT on Feb/2013 ???? i Guess PO forgot to mention that well guess where is the RAVE valve stuck? in the starboard motor of course.

So to summarize, i have spent plenty of hours working on this boat just so i can take it out for a spin, the more i fix the more breaks or find that needs replacement. PO lied from the moment he said hello so now whatever i don't see any receipts for im going to assume it came with the boat in 1997.

Now what i think my options are is....

1. Take both motors out and get 2 SBT or send them to get rebuild.

2. Stop where im at put all back in and put it on Craigslist and let someone with more experience deal with it.

3. Swap it for a smaller boat or even a ski.

4. Part it out and have parts sitting around for the next couple of years.

I dont mind getting dirty but i know how to do small stuff i have never taken a whole motor apart ,just oil changes,spark plugs,brakes,alternators and water pumps and as far as replacing a head gasket on a old toyota because it was marking its territory and the oil was costing me an arm and a leg every week lol. Plus i don't have the special tools needed for a project this big or the friends with the know how either. I would love to do it myself, it would feel great knowing that the boat is running because i did all the work but without an expert close by that i can pick his brains every now and then well.... You get my dilemma

So suggestions ????

So far i know i can send the cores to http://www.seadooengineshop.com $799 ea with core exchange not sure about the shipping.

There is a local place here in Kissimmee $845 ec engine.

If i replace the motors i would rather stay local unless there is a really good deal that does not cost me more than the $845 local.

Again thanks again for all the help in the past and hope the future.

When i got the boat it was sitting for what the Original owner said a couple of months. Boat started fine but the gas had been sitting in the tank for a while so to not mess up the carbs more than they might be i started both motors but only ran for less than a minute.

When i got the boat and started to work on it, flushed the fuel and oil tank,changed fuel and oil filters . Oil lines fuel sender unit and was working on an oil leak there was on the side of the motor from what looks like a metal seal that is in a real PITA place to fix unless i remove the motor.

Well while i decided what to do with that seal, either take out the motor or JB weld the hell out of it i decided to take the RAVE valves out because so far all the info the PO has told me is pretty much a bag of lies. Well,Well surprise surprise valves not only look like they have never been taken out but one of them is stuck in there that it will not move only 1/4 inch up and down but not come completely out so my recent post of a stuck valve.

Now thinking of all this i start looking thru all the paperwork i was given when i got the boat receipt for a battery,fuel filter changes and one for the starboard motor being replaced with a SBT on Feb/2013 ???? i Guess PO forgot to mention that well guess where is the RAVE valve stuck? in the starboard motor of course.

So to summarize, i have spent plenty of hours working on this boat just so i can take it out for a spin, the more i fix the more breaks or find that needs replacement. PO lied from the moment he said hello so now whatever i don't see any receipts for im going to assume it came with the boat in 1997.

Now what i think my options are is....

1. Take both motors out and get 2 SBT or send them to get rebuild.

2. Stop where im at put all back in and put it on Craigslist and let someone with more experience deal with it.

3. Swap it for a smaller boat or even a ski.

4. Part it out and have parts sitting around for the next couple of years.

I dont mind getting dirty but i know how to do small stuff i have never taken a whole motor apart ,just oil changes,spark plugs,brakes,alternators and water pumps and as far as replacing a head gasket on a old toyota because it was marking its territory and the oil was costing me an arm and a leg every week lol. Plus i don't have the special tools needed for a project this big or the friends with the know how either. I would love to do it myself, it would feel great knowing that the boat is running because i did all the work but without an expert close by that i can pick his brains every now and then well.... You get my dilemma

So suggestions ????

So far i know i can send the cores to http://www.seadooengineshop.com $799 ea with core exchange not sure about the shipping.

There is a local place here in Kissimmee $845 ec engine.

If i replace the motors i would rather stay local unless there is a really good deal that does not cost me more than the $845 local.

Again thanks again for all the help in the past and hope the future.

Last edited by a moderator: