crundell73

New Member

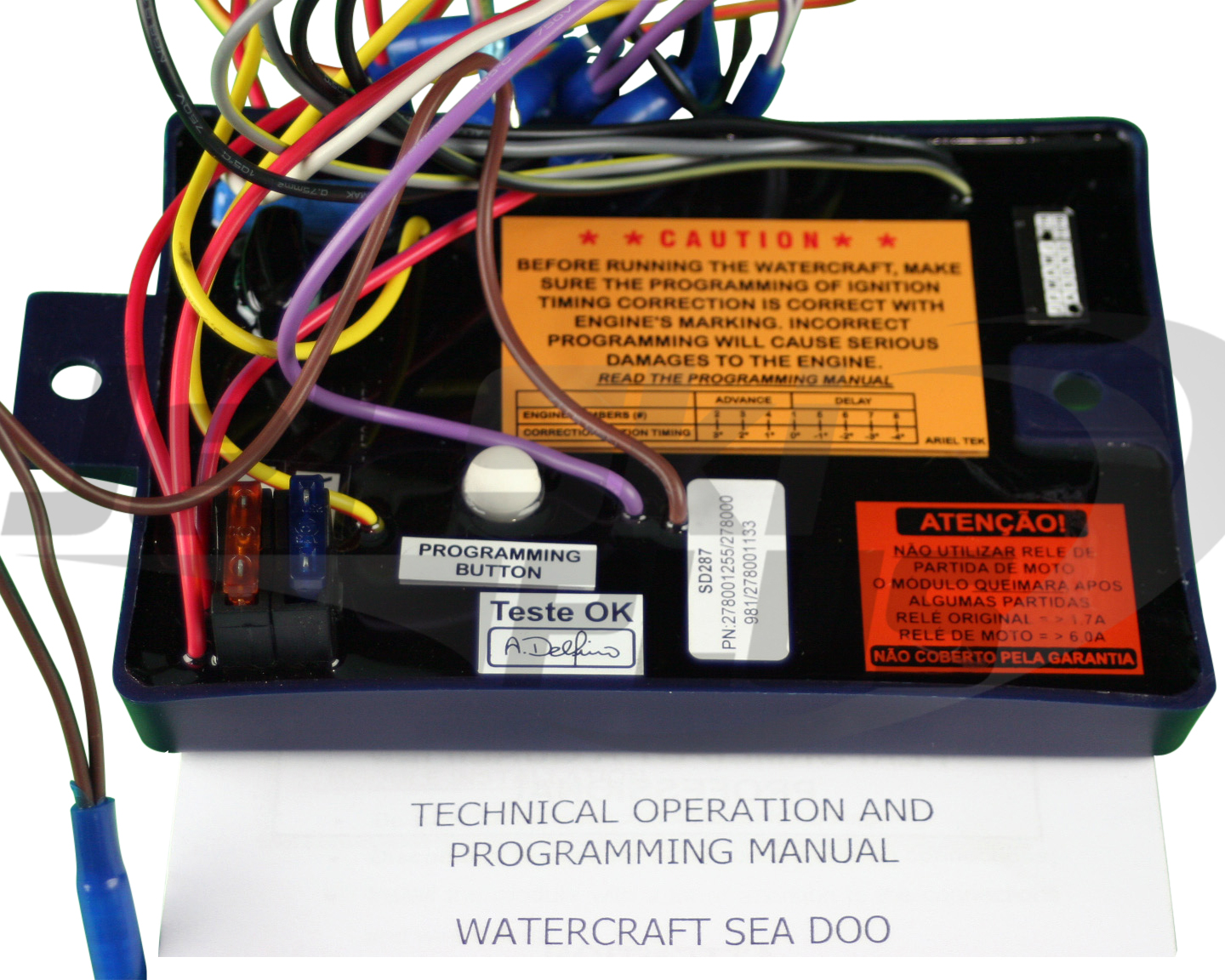

I have a 97 sea-doo 787 that was missing around 3300 rpms and will not want to go over that rpm , will idle just fine and starts really hard .

So I put a test light on it and had a hard time getting the light to work on 1st cylinder , when it did it was innermeten and got no light on 2nd cylinder , now I just had the motor apart to clean out the metal shavings around the stator and trigger , my question is dose it sound like my stator is bad or burnt out , it did have a small burnt smell when I opened the stator plate ?, my timing was advanced about 4-5 degrees .

( also on them jet boats dose any one know if the flush out in the back of the boat is to be closed or open when operating in the water ) Thanks

So I put a test light on it and had a hard time getting the light to work on 1st cylinder , when it did it was innermeten and got no light on 2nd cylinder , now I just had the motor apart to clean out the metal shavings around the stator and trigger , my question is dose it sound like my stator is bad or burnt out , it did have a small burnt smell when I opened the stator plate ?, my timing was advanced about 4-5 degrees .

( also on them jet boats dose any one know if the flush out in the back of the boat is to be closed or open when operating in the water ) Thanks