Cyclopse

Member

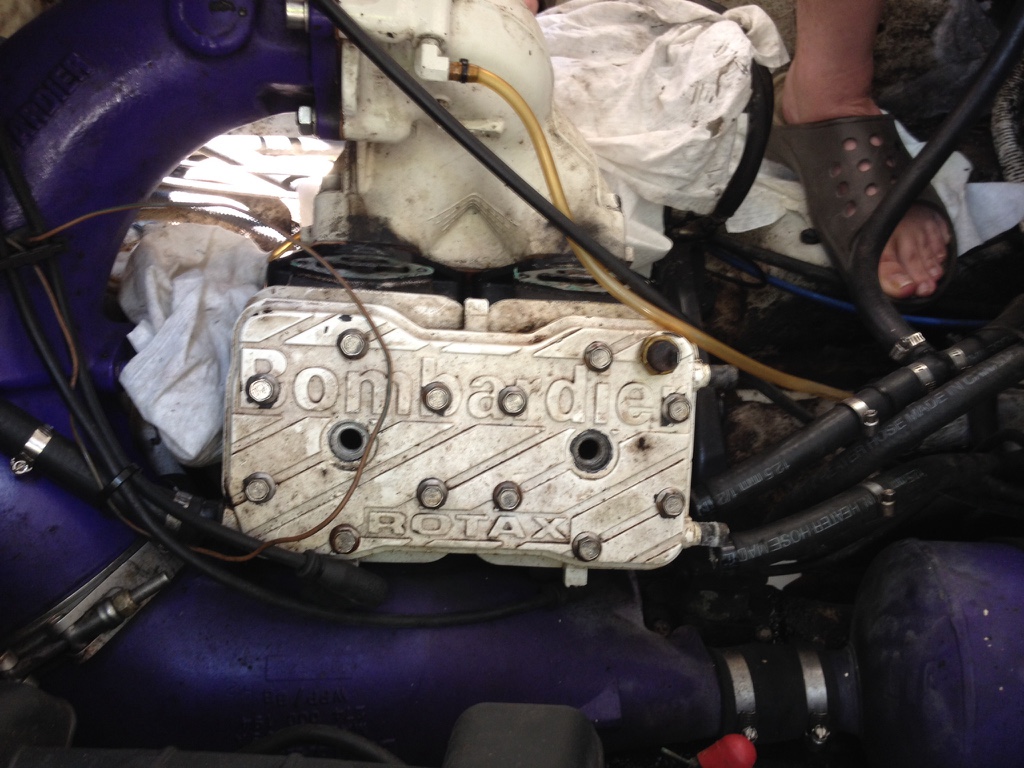

I'm taking a look at a friends 97 Challenger, single 787. On the first ride after having a rebuilt engine installed by a dealer the boat had to be towed back to the dock, the engine would run but the jet pump wasn't turning. Fast forward three years and I've volunteered to take a look. Yep, I'm a sucker for these skis and boats. The driveshaft spins in the PTO so I've disassembled the driveline and the engine can't be turned by hand. I've sprayed some fogging oil in the cylinders, let it soak for half a day but still no PTO movement, I tried a pipe wrench with no luck. The PTO cylinder spark plug had some rust on the tip so I pulled the RAVE and found the Pistons and rings pretty badly rusted. I'll pull the Mag RAVE but you really can't eye into the slot with the exhaust installed. My question is, should I use the fogging oil, Bombardier Lube or two-stroke oil to try and free the Pistons. On the other hand, let me know if you think I'm beating a dead horse here.

Thanks for any and all help.

Sent from my iPad using Tapatalk