soccerdad

Well-Known Member

Took the skis out Tuesday. Amazing day. Both GTX's were a dream. Quick starts, and ran great. Took them both out again today. The green, non-Shamu ski was pulled our tube for about 20 minutes or so. My wife was driving it so nothing radical. The girls wanted more fun, so we switched skis. The tow ski would not start. Finally, I got it running, but it had small backfires and sounded really sick. It would not rev over 5500 RPM. I tried the rectifier with no love. Finally we just rode them back to the ramp. I had a heck of a time starting it, but finally it caught and ran fair at 4000 RPM, but not much higher. Did a compression test and found 155 on the Mag and ZERO on the PTO. :facepalm: WTF!!!

The PTO piston is burnt on the exhaust side.

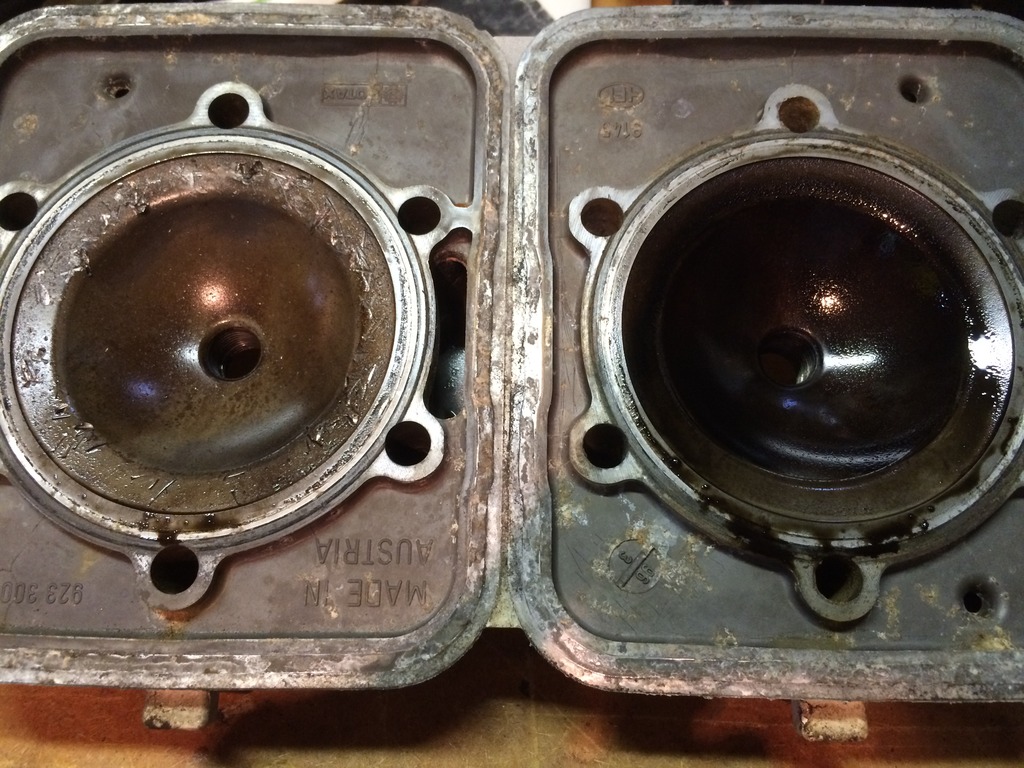

The plugs have me baffled. The dark one is the one that melted and the lighter one is the good Mag plug

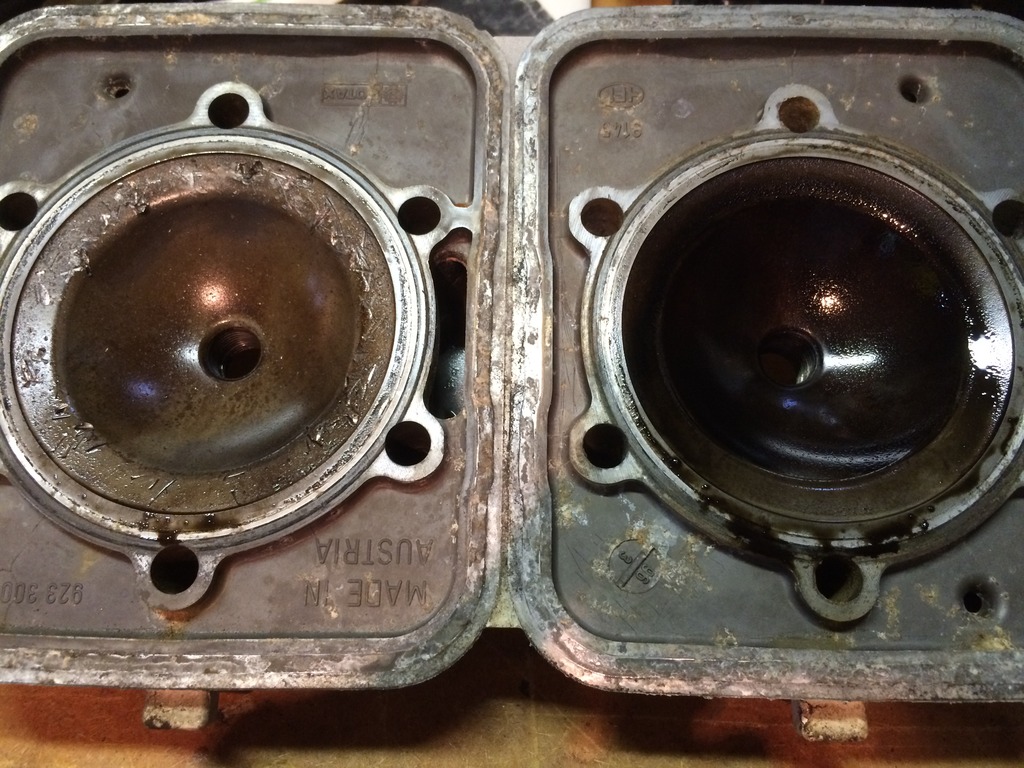

The PTO side head doesn't look that bad to me (except for the shrapnel marks) It does look a lot different than the mag side though. The dark side is the Mag good side. It has a bunch of oil on it, but I did ride it back for about 15 minutes at a pretty slow speed. Although that cylinder was the only thing running the ski.

This is the Mag piston

My only thought is something went wrong in the PTO carb and it burned up. Any other ideas? This is my first motor loss and it really bugs me. I should be receiving new needles and seats Monday. I was going to rebuild those carbs again because it was having a warm start issue. GRRRR.

I do have a spare 787 that came out of the part-out ski. I did start it for a few seconds before I pulled it. It has 150 PSI in both jugs. So I guess that goes in. Any of the NC posse have a motor alignment tool that you want to loan to a friend?

The PTO piston is burnt on the exhaust side.

The plugs have me baffled. The dark one is the one that melted and the lighter one is the good Mag plug

The PTO side head doesn't look that bad to me (except for the shrapnel marks) It does look a lot different than the mag side though. The dark side is the Mag good side. It has a bunch of oil on it, but I did ride it back for about 15 minutes at a pretty slow speed. Although that cylinder was the only thing running the ski.

This is the Mag piston

My only thought is something went wrong in the PTO carb and it burned up. Any other ideas? This is my first motor loss and it really bugs me. I should be receiving new needles and seats Monday. I was going to rebuild those carbs again because it was having a warm start issue. GRRRR.

I do have a spare 787 that came out of the part-out ski. I did start it for a few seconds before I pulled it. It has 150 PSI in both jugs. So I guess that goes in. Any of the NC posse have a motor alignment tool that you want to loan to a friend?