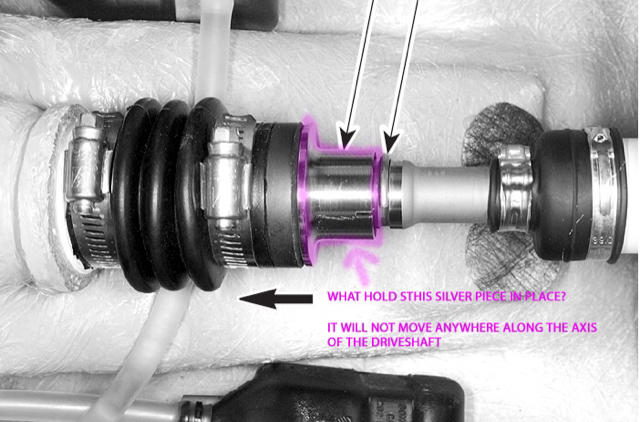

Hi, it sounds as if there's rubber bits up inside the carbon seal bellows interfering with the carbon seal as the driveshaft is rotating. I'd guess in this case the carbon seal can't seal against the rotating stainless steel ring on the drive shaft and this allows air to become sucked from the bilge into the impeller, the impeller will just spin in the air and cannot pull/push water through the pump. So in this case the engine should rev fine, just the jet pump doesn't work well.

I'm not sure why the drive shaft rubber cannot just be removed and the rubber coating exfoliated, the diameter will be smaller, of course. IMO, Seadoo should've covered the shaft using nylon instead, why they covered the shaft to prevent rust is a little mysterious to me, salt will get down inside under the rubber anyway unless the adhesion is perfect and that's obviously the case.

As far as aftermarket shaft is concerned, there might be some subtle differences but the important parameters would be proper length and spline fit. Like mine and most, the drive shaft on yours I believe has both ends splined, these splines are engaged at the pump into the impeller and at the engine into the power takeoff coupling.

It's fairly common for the splines inside the power takeoff and drive shaft might wear if there's a lack of lubricating grease in the spline coupling, and if the wear is great enough the engagement will become poor, torque from the engine isn't transferred through the coupling into the drive shaft if the splines are slipping. Thus the impeller isn't firmly coupled to the engine crankshaft.

If the engine crankshaft is misaligned (from parallel and center with the drive shaft, this places a side load on the power takeoff and drive shaft splines and will cause abnormal wear inside the coupling as the engine rotates, the coupling is no longer able to transfer torque from the engine through the drive shaft and into the impeller, slipping occurs.

Normally that takes many hours of operation, probably near 1,000 or more, before the splines are no longer serviceable.

Aftermarket parts can sometimes be superior to factory parts. For instance, the factory might cheap out and use a low grade of steal to save a buck then coat it in rubber to avoid rusting. An aftermarket drive shaft might be made of stainless steel for instance, which won't corrode under most conditions.

Whatever is going on in your case, either the carbon seal isn't working properly to keep air from being sucked into the impeller, or it's possible your splines are worn and thus slipping.

There might be some perceptible amount of play in the splines normally but not a whole lot, not enough to allow the splines to lose coupling and slip. If you think the torque from the engine isn't being transferred to the impeller, the splines in the coupling and shaft might be worn out, an el-cheapo steel drive shaft might be made of soft steel that cannot take the engine torque, the splined end might strip off.

If I was making and selling a drive shaft, it wouldn't be a soft steel, and I'd try to use stainless if possible. Another thought, maybe seadoo couldn't use stainless for some reason other than just cost?

Sorry I don't have definitive answers for you but if I was you I'd consider if it's possible to remove the rubber and continue using the drive shaft assuming it's not worn out in the splines. If the splines are trashed then the engine coupler probably is as well, and both need to be replaced.

I was thinking your rubber coating on the shaft was delaminating and interfering with the carbon seal ability to keep air inside the bilge, but it's possible instead the shaft splines are toast.

There must be 1,000 ways to skin a kitty-cat.... (NOT that I would or have!)

Even sliding a section of nylon tubing tightly over the drive shaft might work if the diameter is too small and creating some kind of problem with keeping the carbon seal centered?

BTW, the carbon seal is lubricated and cooled by water inside the pump tunnel, it will overheat the rubber bellows and maybe other stuff if the engine is run too long out of water. I prefer the older seadoo carbon seal (like the one you have) for it's simplicity, not sure why seadoo "upgraded" except the rubber coating idea probably wasn't exactly brilliant.

The big nut on the drive shaft of the new design seems cumbersome although it might be superior, I don't have any idea.

Also, if the engine mounts are broken the engine will tend to move around in the bilge and this creates side-loading of the splines thus accelerating spline wear and difficulty in obtaining a good carbon ring seal (due to misalignment).

Anyway, check it out and try to determine the issue causing problems then work toward a solution. I hate to see people spend money on parts if it's unnecessary.