A.J.C.

New Member

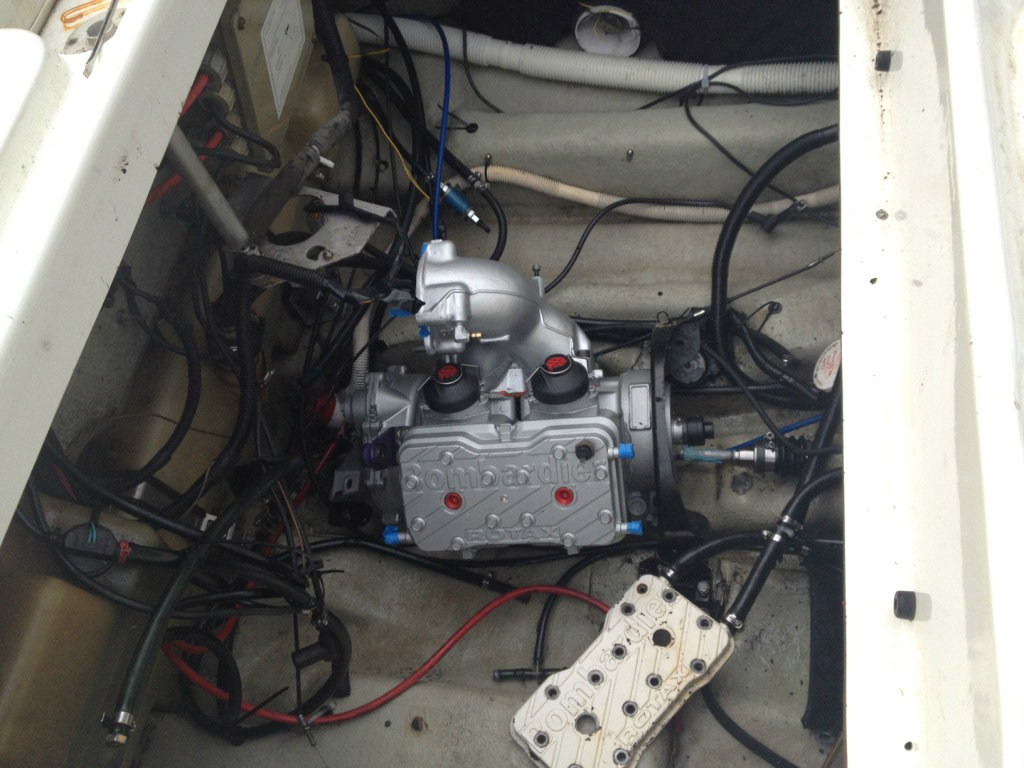

Hey guys, I purchased a 1997 Sea Doo Challenger with the single 787cc engine. It came with a new engine (not installed) and 2004 trailer.

The old engine had already been removed by the previous owner since it was seized. I was left with a very dirty engine compartment and parts/bolts everywhere. I'm going to post my progress and ask a lot of questions so I appreciate the help in advance!

Here is what I'm working with:

Today I cleaned the engine compartment. Man, it was caked in oil. I scrubbed and rinsed it all day.

From this:

To this:

Here is my first of many questions. The original carburetors are pretty trashed. They are full of sludge and most of the phillips head bolts are stripped from a previous rebuild (not me). I bought some carbs off a 96' GSX. They look very similar minus a few components. I guess some of the parts can be swapped from my original carbs but I'm just speculating. Let me know if you think I can use these carbs as is or need to modify them. Here are some pics of the two sets of carbs.

Original Carbs

New Carbs

The old engine had already been removed by the previous owner since it was seized. I was left with a very dirty engine compartment and parts/bolts everywhere. I'm going to post my progress and ask a lot of questions so I appreciate the help in advance!

Here is what I'm working with:

Today I cleaned the engine compartment. Man, it was caked in oil. I scrubbed and rinsed it all day.

From this:

To this:

Here is my first of many questions. The original carburetors are pretty trashed. They are full of sludge and most of the phillips head bolts are stripped from a previous rebuild (not me). I bought some carbs off a 96' GSX. They look very similar minus a few components. I guess some of the parts can be swapped from my original carbs but I'm just speculating. Let me know if you think I can use these carbs as is or need to modify them. Here are some pics of the two sets of carbs.

Original Carbs

New Carbs

Last edited by a moderator: