Without the bumper, I have seen shafts spin as they are not in the correct alignment in regards to depth.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

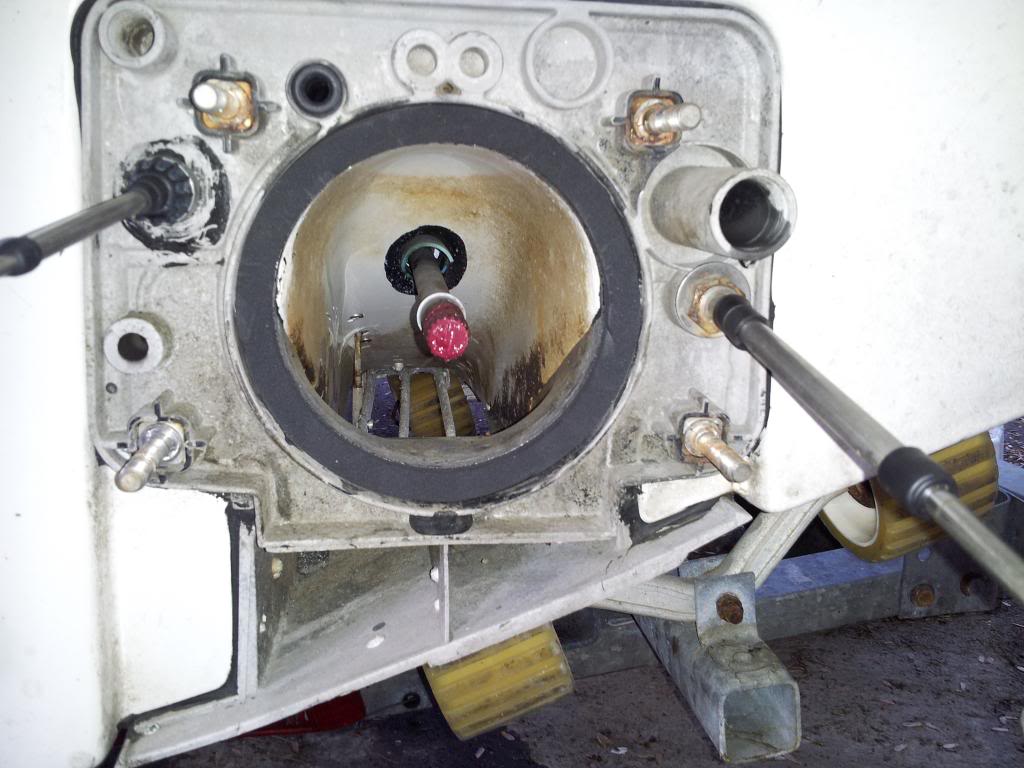

here are some picsRemember this is a custom application. Not your normal oem bombardier driveline and engine package. Adjustments are going to be different since you have a different engine etc. Let's get some more detailed pictures up of the boat, driveline, engine, couplings etc.

Plus we want to see more about how this was constructed and if it is an efficient combo/swap.

Rob

Remember this is a custom application. Not your normal oem bombardier driveline and engine package. Adjustments are going to be different since you have a different engine etc. Let's get some more detailed pictures up of the boat, driveline, engine, couplings etc.

Plus we want to see more about how this was constructed and if it is an efficient combo/swap.

Rob

Did not find a bumper in there....BUT I did fish out 2 small washers covered in grease. Im going to take off the allen head bolts and see if its "stuck" in there.

How hard to align motor? I never ever tried it or know anyone who has attempted it

I'll consider the PTO and back OEM, so bumpers, end play and alignment still should work like the original set-up.

I'll assume they used the washers like shims instead of the bumper. If everything lines up, to quickly add more tension to the boot/carbon seal you can loosen the rear hose clamp and push the boot towards the PTO and put a cable tie around the thru hull fitting. (See yellow cable tie in pic) Thanks Manolocross for the pic

Sent from my SGH-T889 using Tapatalk

Yes...."that"

That retaining ring is blue plastic, correct? If so your fine.

Sent from my SGH-T889 using Tapatalk