CollinCountyCab

New Member

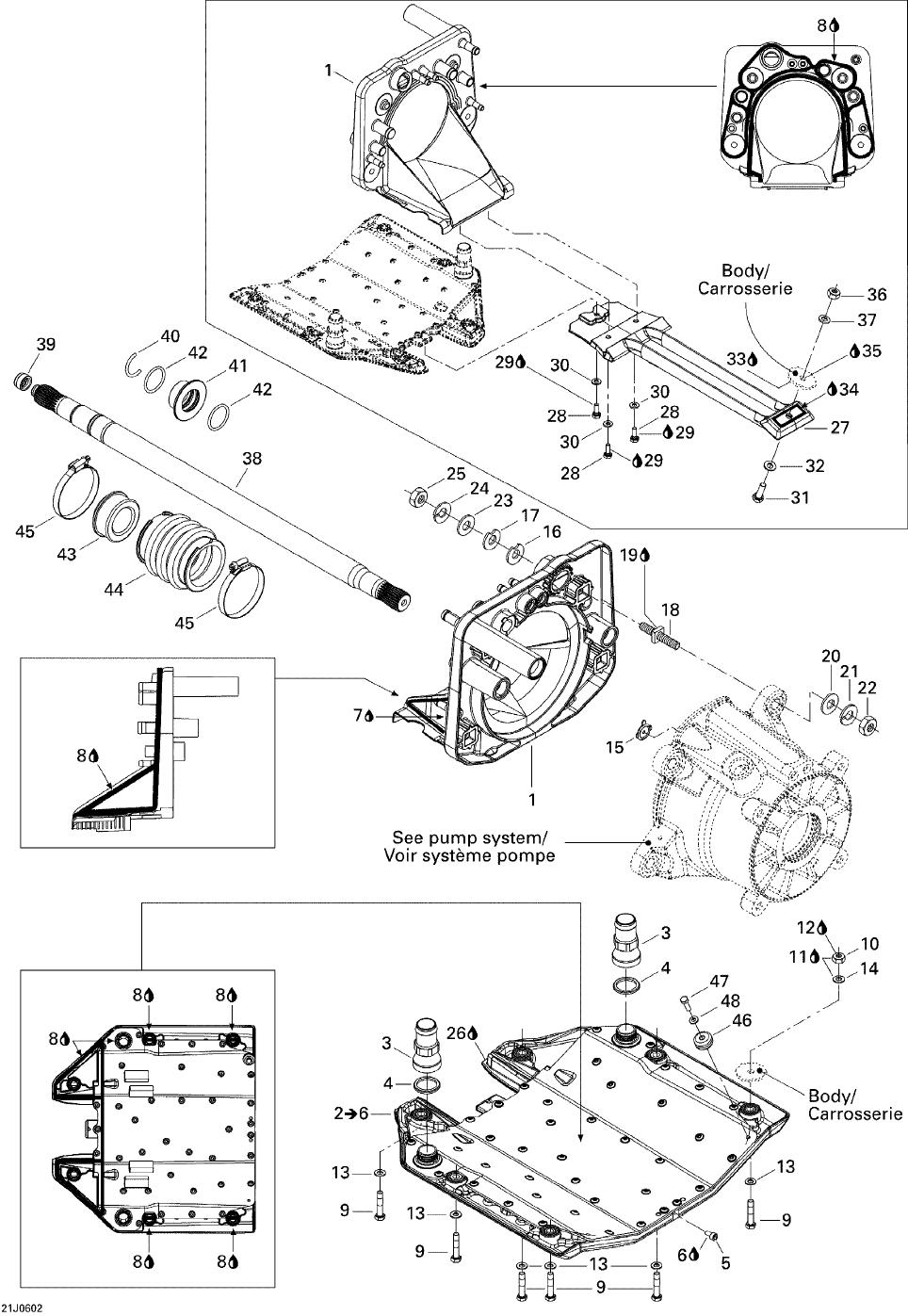

Launched for the first time and in lake couldnt get it to move back or forward. Shaft was spining but boat was not. I had to rev it up super high to get it to move....like 4k RPM. Here is a photo of pump. Look bad? Motor is not Super Charged and runs great (i think)

Any advice?

Thanks

Any advice?

Thanks