Dr Honda

Well-Known Member

Hi Guys,

Well... this post isn't going to be as long as I hoped. It was hot, and I forgot to grab the camera.

Anyway... As some of you guys know... I'm not a fan of surge brakes... and my islandia project boat needed new brakes. So, I made the decision to remove the surge brake, and replace it with an electric unit. Even though, I didn't get too many pictures... it really is a straight forward install. More or less... you remove the old brakes, and bolt on the new units.

There were several reasons I decided to not rebuild the surge brake system, that was on the trailer.

1) There was no fluid in the Master after I got home from my original drive from MI to PA. (so I would have to figure out where it went, and fix the issue)

2) There may have been multiple issues after I got into the system. (ie. EXPENSIVE)

3) Potential Legal issues. FED DOT says that they aren't legal, although, they have never been denied.

4) This system didn't have the reverse lock solenoid, so I had to do something for a lock out.

5) Pittsburgh is very hilly, and surge brakes are a pain in that situation. They are known to drag going down hill, even at highway speeds.

6) Did I mention expensive?? (let's face it... I'm cheap)

I would list some "Pro's" for surge brakes... but I personally can't find any. There are people who say that they are more water/corrosion resistant... but the units I removed where "Std duty" brakes. So... if they were bein dipped in salt water... they would have been rusted solid.

OK.... about the electric brakes.

PRO's:

1) They are very cheap. Even if I need to replace a magnet, or brake shoes.... I can buy an entire backing plate (with all new parts) for $40 or less. (that's less than the shoes for the surge brake)

2) I can control the braking force from the cab. (safer in bad conditions, or on gravel roads)

3) When they are wet... I can put just a touch of power on them (from the control) to dry them out.

4) They work backing down a steep boat ramp. (safer)

5) don't have to worry about fluid, or bleeding the system.

CON's:

1) some people say they rust easier when used in a boat trailer. (but they are made with the same drums, and painted backing plates. So, I don't see it)

2) Some people say... "Electricity, and water don't mix". (This is true, but it's low voltage, and the magnets, and wiring are sealed. Also, under normal conditions, I'm only feeding them about 4 volts, at 1 amp)

As you can see... the Electric CON's don't seem like con's to me.

OK... as I removed the old system... the brake drums and shoes looked like they were never even used. They are in great condition!! But, the few drops of fluid that cam out of the hoses, was black, and full of sludge. As some of you guys know, the boat came from a rental shop... so the trailer probably didn't have too many miles on it. And, since they were only towing it about a mile (to their ramp) they probably didn't care that the brakes weren't working. But, after pulling the system apart... I would have had to replace all the lines, the Master, and the 2 wheel cyl's.

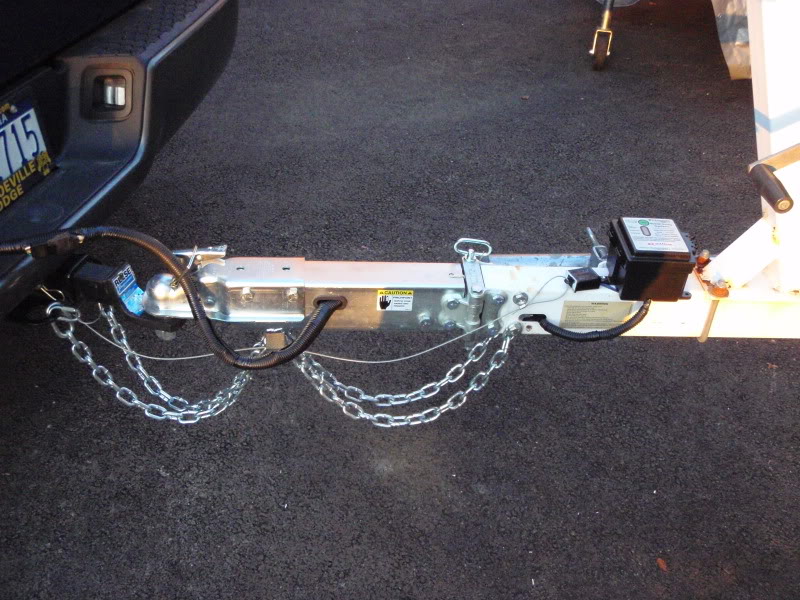

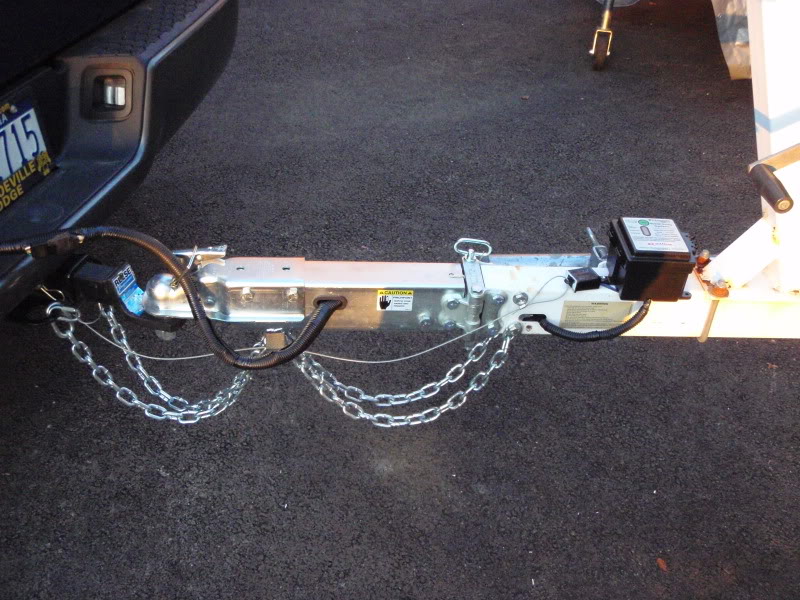

Once it was off... the first thing to address was the missing 2' of trailer tongue that the surge master cyl made up. That was easily fixed with the addition of a Fulton swing away tongue. I had to trim about 4" from the trailer... drill a few holes... and simply bolt it on. The instructions with the kit are easy to follow. And... the new parts look so much better than the rusty parts that came off.

After that... I bolted on the new electric brakes. That was also a very simple job. More or less... you just bolt on the new backing plates, and install the drum like any other hub/brake unit. With that said... my flange on the axle had extra length on the bottom, and it needed a small trim so the new backing plates could sit flat.

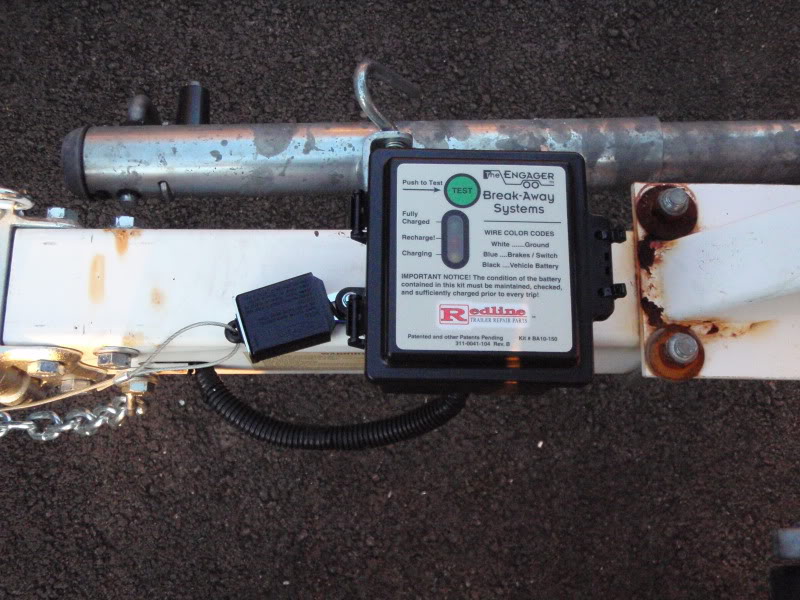

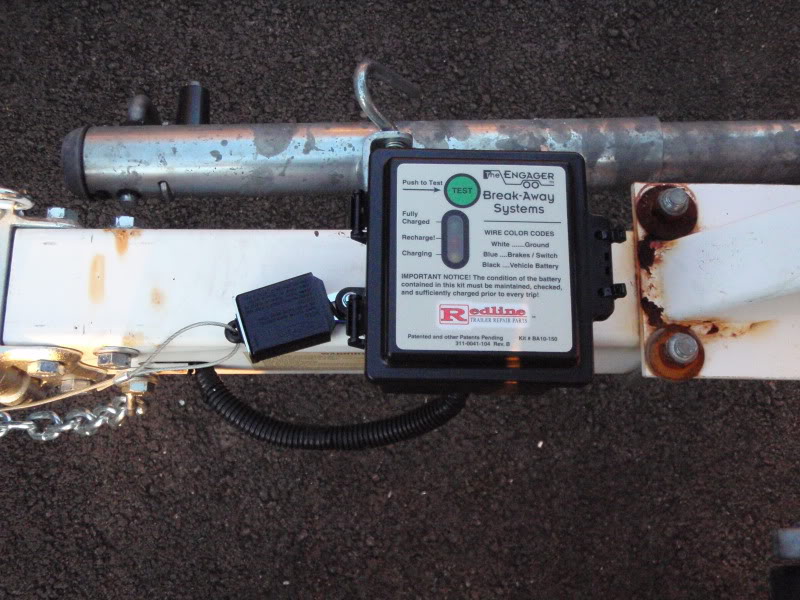

The wiring was also easy. You basically just run the new brake wire in series from the magnets, and up to the connector. Needless to say, you will be switching from a flat 4 connector to a round 7 pin. The only thing you need to think about is the battery box, and the brake-away switch. I mounted mine just behind the tongue hinge. There are 3 wires on the box. One is battery power (that goes directly to the trailer plug) and that charges the battery when hooked to the truck. One goes to the ground... and one goes to the hot wire for the brakes. (The switch goes in-line with that)

To solve the potential water issues with the wiring... I soldered all the connections, and covered them in heat-shrink. I also added a waterproof plug to each of the magnets, so I could unplug the backing plate for easy removal.

The entire kit for the conversion was about $190 from ebay. That came with wire, drums, bearings, seals,backing plates with all the brake components installed, lug nuts, dust caps, brake-away switch, battery, battery box, and a trickle charger.

I will make updates to this thread as I put some miles on them... and as always, I am open to questions, and/or debates.

Well... this post isn't going to be as long as I hoped. It was hot, and I forgot to grab the camera.

Anyway... As some of you guys know... I'm not a fan of surge brakes... and my islandia project boat needed new brakes. So, I made the decision to remove the surge brake, and replace it with an electric unit. Even though, I didn't get too many pictures... it really is a straight forward install. More or less... you remove the old brakes, and bolt on the new units.

There were several reasons I decided to not rebuild the surge brake system, that was on the trailer.

1) There was no fluid in the Master after I got home from my original drive from MI to PA. (so I would have to figure out where it went, and fix the issue)

2) There may have been multiple issues after I got into the system. (ie. EXPENSIVE)

3) Potential Legal issues. FED DOT says that they aren't legal, although, they have never been denied.

4) This system didn't have the reverse lock solenoid, so I had to do something for a lock out.

5) Pittsburgh is very hilly, and surge brakes are a pain in that situation. They are known to drag going down hill, even at highway speeds.

6) Did I mention expensive?? (let's face it... I'm cheap)

I would list some "Pro's" for surge brakes... but I personally can't find any. There are people who say that they are more water/corrosion resistant... but the units I removed where "Std duty" brakes. So... if they were bein dipped in salt water... they would have been rusted solid.

OK.... about the electric brakes.

PRO's:

1) They are very cheap. Even if I need to replace a magnet, or brake shoes.... I can buy an entire backing plate (with all new parts) for $40 or less. (that's less than the shoes for the surge brake)

2) I can control the braking force from the cab. (safer in bad conditions, or on gravel roads)

3) When they are wet... I can put just a touch of power on them (from the control) to dry them out.

4) They work backing down a steep boat ramp. (safer)

5) don't have to worry about fluid, or bleeding the system.

CON's:

1) some people say they rust easier when used in a boat trailer. (but they are made with the same drums, and painted backing plates. So, I don't see it)

2) Some people say... "Electricity, and water don't mix". (This is true, but it's low voltage, and the magnets, and wiring are sealed. Also, under normal conditions, I'm only feeding them about 4 volts, at 1 amp)

As you can see... the Electric CON's don't seem like con's to me.

OK... as I removed the old system... the brake drums and shoes looked like they were never even used. They are in great condition!! But, the few drops of fluid that cam out of the hoses, was black, and full of sludge. As some of you guys know, the boat came from a rental shop... so the trailer probably didn't have too many miles on it. And, since they were only towing it about a mile (to their ramp) they probably didn't care that the brakes weren't working. But, after pulling the system apart... I would have had to replace all the lines, the Master, and the 2 wheel cyl's.

Once it was off... the first thing to address was the missing 2' of trailer tongue that the surge master cyl made up. That was easily fixed with the addition of a Fulton swing away tongue. I had to trim about 4" from the trailer... drill a few holes... and simply bolt it on. The instructions with the kit are easy to follow. And... the new parts look so much better than the rusty parts that came off.

After that... I bolted on the new electric brakes. That was also a very simple job. More or less... you just bolt on the new backing plates, and install the drum like any other hub/brake unit. With that said... my flange on the axle had extra length on the bottom, and it needed a small trim so the new backing plates could sit flat.

The wiring was also easy. You basically just run the new brake wire in series from the magnets, and up to the connector. Needless to say, you will be switching from a flat 4 connector to a round 7 pin. The only thing you need to think about is the battery box, and the brake-away switch. I mounted mine just behind the tongue hinge. There are 3 wires on the box. One is battery power (that goes directly to the trailer plug) and that charges the battery when hooked to the truck. One goes to the ground... and one goes to the hot wire for the brakes. (The switch goes in-line with that)

To solve the potential water issues with the wiring... I soldered all the connections, and covered them in heat-shrink. I also added a waterproof plug to each of the magnets, so I could unplug the backing plate for easy removal.

The entire kit for the conversion was about $190 from ebay. That came with wire, drums, bearings, seals,backing plates with all the brake components installed, lug nuts, dust caps, brake-away switch, battery, battery box, and a trickle charger.

I will make updates to this thread as I put some miles on them... and as always, I am open to questions, and/or debates.