-

This site contains eBay affiliate links for which Sea-Doo Forum may be compensated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

97 GTX - Am I too Lean? - High RPM Power Loss - At Lake

- Thread starter digital sol

- Start date

- Status

- Not open for further replies.

digital sol

Member

Unplug the red wire on the rectifier and see what happens

This may require something different as currently I am using an aftermarket OSD external rectifier with custom OSD wiring harness to bypass the factory unit as the factory rectifier never charged the battery. I will look back at my pictures and see what goes where, off hand its kind of a blur at the moment without having the ski here to look at.

To add to the confusion my folks picked up the ski and the shop claimed they were nearly positive the issue was resolved with the carb work they did but they didn't tell them anything specific they fixed or did inside the carbs nor did they actually *lake test" the ski. I wont be able to make it down next weekend but trying to talk my brother into taking it out for me to run it and see if they are full of shit or what. Its 3.5 hours for me to get down there and I have minimal tools there so if its still an issue I will most likely be having it towed here for me to work on. Kind of mute to test anything else until I get someone to lake test it for me and go from there. Thanks for all the help and advice thus far. Hopefully I will have some answers by next weekend.

digital sol

Member

I didnt want to start a brand new thread for this but I finally got the ski back from the shop, same symptoms as before. Talked to two different mechanics there and got two different story's on what they did, tested or thought it was. Basically a huge waste of time and money they charged me.

Anyways....I am heading down in a couple weeks to bring the ski back to STL. I was unable to find any recommended shops here in STL so I will be back at it working on it myself over winter again. I wanted to get a check list of everything to check and do and pick your brains on this issue.

To recap the issue

-ski wont hit higher rpms in the water, meaning anything above the 5k+ mark. It will rev higher if i hit a wave and get the ski bottom out of the water a tad then RPM dies immediately when it hits the water.

Note: Shop claims even on a trailor it wont rev over 5k, I will confirm this when I bring it home

-fuel baffle was replaced with a brand new unit *last baffle was repaired but the weld used was eaten by the gasoline and was not sealed properly anymore*

-issue occurred regardless of which setting the fuel selector was set to

-gas tank still never *vented* or hissed anything i removed the gas tank but both those valves were replaced with oem units

-pulling choke while riding WOT did not increase RPM's they decreased them

-ski runs fine below the 5k mark at partial throttle, plugs were a little rich but i ran partial throttle all weekend long and am on pre-mix so its to be expected

Things To Check:

-Check both check valves and blow air through them to verify they work

--Which valve lets air out, which valve lets air in?

-Check the timing which involves removing the carbs and valve cover if im not mistaken and using a dial wheel *will research further*

-Check fuel system for leaks by pressurizing the system *still researching this as far as where to test/how to test*

-Might also send me carbs off again just to have them inspected. I rebuilt them myself and then the shop claimed they fixed something inside of them this last visit but they couldnt tell me exactly what they did or replaced...sounded more like they needed to say they installed something before they charged me $300 to tell me my ski still dosnt work lol.

Anyways....I am heading down in a couple weeks to bring the ski back to STL. I was unable to find any recommended shops here in STL so I will be back at it working on it myself over winter again. I wanted to get a check list of everything to check and do and pick your brains on this issue.

To recap the issue

-ski wont hit higher rpms in the water, meaning anything above the 5k+ mark. It will rev higher if i hit a wave and get the ski bottom out of the water a tad then RPM dies immediately when it hits the water.

Note: Shop claims even on a trailor it wont rev over 5k, I will confirm this when I bring it home

-fuel baffle was replaced with a brand new unit *last baffle was repaired but the weld used was eaten by the gasoline and was not sealed properly anymore*

-issue occurred regardless of which setting the fuel selector was set to

-gas tank still never *vented* or hissed anything i removed the gas tank but both those valves were replaced with oem units

-pulling choke while riding WOT did not increase RPM's they decreased them

-ski runs fine below the 5k mark at partial throttle, plugs were a little rich but i ran partial throttle all weekend long and am on pre-mix so its to be expected

Things To Check:

-Check both check valves and blow air through them to verify they work

--Which valve lets air out, which valve lets air in?

-Check the timing which involves removing the carbs and valve cover if im not mistaken and using a dial wheel *will research further*

-Check fuel system for leaks by pressurizing the system *still researching this as far as where to test/how to test*

-Might also send me carbs off again just to have them inspected. I rebuilt them myself and then the shop claimed they fixed something inside of them this last visit but they couldnt tell me exactly what they did or replaced...sounded more like they needed to say they installed something before they charged me $300 to tell me my ski still dosnt work lol.

Last edited by a moderator:

Mickirig1

Well-Known Member

Have you had it out on the water with a direct line from tank to carbs? Still does it? You did test pop off when you rebuilt carbs? Have you looked at the pulse line or replaced it? Correct diameter line? New carb base gaskets? Still using stock air box?

Might consider replacing the expensive gaskets in the carbs if not done already. You figure they are nearly 20 years old. You did clean them well? Blow out passages? Might consider replacing the jets. All this is cheaper then new carbs. Someone on forum maybe able to look at them. Most of the shops really don't want to touch anything older then 2005. They look at me and talk to me like I am retarded / stupid! They wrinkle their lips and say: "WE don't stock ANY OF THOSE PARTS THAT OLD"

Might consider replacing the expensive gaskets in the carbs if not done already. You figure they are nearly 20 years old. You did clean them well? Blow out passages? Might consider replacing the jets. All this is cheaper then new carbs. Someone on forum maybe able to look at them. Most of the shops really don't want to touch anything older then 2005. They look at me and talk to me like I am retarded / stupid! They wrinkle their lips and say: "WE don't stock ANY OF THOSE PARTS THAT OLD"

digital sol

Member

Have you had it out on the water with a direct line from tank to carbs? Still does it? You did test pop off when you rebuilt carbs? Have you looked at the pulse line or replaced it? Correct diameter line? New carb base gaskets? Still using stock air box?

Might consider replacing the expensive gaskets in the carbs if not done already. You figure they are nearly 20 years old. You did clean them well? Blow out passages? Might consider replacing the jets. All this is cheaper then new carbs. Someone on forum maybe able to look at them. Most of the shops really don't want to touch anything older then 2005. They look at me and talk to me like I am retarded / stupid! They wrinkle their lips and say: "WE don't stock ANY OF THOSE PARTS THAT OLD"

Yes direct line still happened.

Yes pop off was I believe 32-33psi I can check my notes

Pulse line was replaced two years ago but not replace since then. It's same size as all the fuel lines

Yes new carb base gaskets but need to check for leaks, heard there was a leak test kit available for this but researching still

Yes carbs were rebuilt using Oem kit with new jets and all from osd parts. Was my first carb rebuild but I documented the rebuild in my resto thread.

Haha that's pretty much been the response I've got or they claim to be pro's and then are clueless after I drop it off. Hopefully I answered all the questions I am on my phone. In going to go back through many of these things once I get it home from the lake for sure.

Sportster-2001-951C-Stock

Well-Known Member

Didn't the 97 have a service builtin about the rave valves

"It will rev higher if i hit a wave and get the ski bottom out of the water a tad then RPM dies immediately when it hits the water."

Yep, might be RAVES aren't actuating. Are the RAVE bellows aftermarket or OEM? Some aftermarket bellows are wrong, won't allow full open movement.

Also might be an issue with water box valve not moving correctly, too much water in expansion pipe? Is valve able to move freely or weeds/dirt stuck in pintle?

My other question is if engine hesitates at WOT, lean surging? If yes this could be a carb issue with the metering arm adjustment. Check height of metering arm and describe observation. Just b/c it pops where you want doesn't necessarily mean the geometry is correct.

FWIW, if you bent the metering arm substantially to set pop this raises a red flag. Maybe you didn't, hard to know. Someday I'll get around to writing a clever poem about checking pop and setting arm position but having trouble getting started.....

I read somewhere there's smoke in this bilge indicative of an exhaust leak, is this true? Test riding with seat off will allow more fresh air.

Last edited by a moderator:

Sportster-2001-951C-Stock

Well-Known Member

Unplug the red wire on the rectifier and see what happens

This is an excellent point as well.

Strizzo

Well-Known Member

those plugs don't look bad to me, bad lean would be white irrc. one thing about running and pulling the choke, if you have an air leak in the fuel delivery, and pull the choke, it will die right there (no more fuel to give) if its lean because of the carb setting, it will pick up.

Sportster-2001-951C-Stock

Well-Known Member

It's potentially lean unless it's obviously rich. 2-stroke bible 4-stroking babble. Turn it up (in all the right places) until you hear the sweet sound of 4-stroking then back it down just enough till it cleans up. If your adjusters and increasing jet orifices don't work as they should to increase fuel, there's something wrong (such as a hunk of junk stuck in a passage, so inspect carefully).

Attachments

Last edited by a moderator:

Sportster-2001-951C-Stock

Well-Known Member

-Check fuel system for leaks by pressurizing the system *still researching this as far as where to test/how to test*

All that work and posting without confirming this leaves you dead in the water, do you have this figured out yet?

Mickirig1

Well-Known Member

You use a pop off tester. Clamp a section and bring pressure up to 5 psi and see how long it holds. The vents I do believe pop at lower then 5 psi. The idea is to find a connection or a gasket that is leaking in or out pressure. Two piece oil tanks can have leaks at the seams. You will know it when you find it. The section will not hold pressure at all. One of the biggest places for leaks is the water separator / fuel filter under the front hatch. The flat gasket cracks or no longer holds pressure. They are like $25 to replace.

digital sol

Member

Didn't the 97 have a service builtin about the rave valves

Not sure tbh

digital sol

Member

"It will rev higher if i hit a wave and get the ski bottom out of the water a tad then RPM dies immediately when it hits the water."

Yep, might be RAVES aren't actuating. Are the RAVE bellows aftermarket or OEM? Some aftermarket bellows are wrong, won't allow full open movement.

Also might be an issue with water box valve not moving correctly, too much water in expansion pipe? Is valve able to move freely or weeds/dirt stuck in pintle?

My other question is if engine hesitates at WOT, lean surging? If yes this could be a carb issue with the metering arm adjustment. Check height of metering arm and describe observation. Just b/c it pops where you want doesn't necessarily mean the geometry is correct.

FWIW, if you bent the metering arm substantially to set pop this raises a red flag. Maybe you didn't, hard to know. Someday I'll get around to writing a clever poem about checking pop and setting arm position but having trouble getting started.....

I read somewhere there's smoke in this bilge indicative of an exhaust leak, is this true? Test riding with seat off will allow more fresh air.

Sorry for the delays in reply's I have been consumed with house repair stuff but I really appreciate the reply's!

-oem valves *cleaned & reinstalled*. I will dig up pics and post them of the condition of the valves

-cleaned them during my restoration

-oem bellows *red*>checked for tears and they were clean so I re-used. One of them did have oil/gas on it when removed because the boot slipped off but I install the springs around them both to keep the boots snug

-water valve/regulator with red top was removed & I replace the internals. There was a rip in the boot but the clamp having rust on it and also the exhaust it screws into had a noticble hard water/burn stain where it was leaking at the stem. Now one thing I will mention is when I removed this it had "1" extra washer installed inside of it. I removed this extra shim as the manual did not show any extra washer inside of it. I do see water trickle out at idle and once I give her gas and cruise i see water coming out of the pisser in the rear of the ski like usual. Seems like normal operation there and there are 0 leaks @ the exhaust like before the restoration

When driving the ski it does not seem like lean surging. Anything below 5k rpm runs pretty smooth and feels healthy. I can pull the choke and the ski actually loses power at WOT so I dont think its a lean condition. Plugs look rich from partial throttle driving but its expected w/premix & running partial throttle. WOT runs showed a nice brown plug but I cant get it over that 5k mark.

I don't believe the arm is bent in the carb but I will take them off and inspect them. It was weird during the time of rebuilding the carbs I had to run two different springs to get the same pop off pressure but I noted that in my restoration thread and didnt see anyone mention anything weird about it other than make sure they match. I used oem kits from MSD and had a hard time getting them to pop off at the same pressure. I changed one of their springs with an oem spring & got them both at the same pressure.

Exhaust leak was @ the big band clamp at the exhaust portion. I ended up tightening this bolt and did not see any more exhaust smoke or anything inside the ski. I removed the seat and took it for a cruise and did not see any leaks or see any change in ski performance. Originally the entire exhaust was removed, cleaned, painted & reinstalled during the restoration and I wasnt sure how tight it needed to be so I left it tight but not over the top. I gave it one more full turn and since then havnt seen any type of indication of an exhaust leak at the clamp.

digital sol

Member

This is an excellent point as well.

This is a confusing option to me because I am not using the oem rectifier. I am using an OSD aftermarket unit with a plug n play harness for my ski. I could remove the new rectifier completely and retest but would the rectifier prevent the ski from revving higher? I was under the impression it simply charges the battery as you drive it.

I went with a aftermarket unit because the factory unit was replaced at a shop a while ago and the ski still had charging issues and also constant 12v low on indicator. After switching to the OSD unit & charging the battery the 12v low has not come back on where as before it was constant while driving for the most part.

digital sol

Member

All that work and posting without confirming this leaves you dead in the water, do you have this figured out yet?

No unfortunately not. I wanted the shop to do this while it was there because my tools and pop-off tester etc was 3.5 hours away. They didnt do any of this basic testing so I am going to do it myself once I get it home. Some personal stuff came up so I have not made a weekend trip down there to bring it home just yet but checking this is my #1 priority when it gets back here.

Carbs are still a new breed to me and the manual is a little confusing on this but I have been watching some standard fuel pressure testing for carb's and will be checking this first thing as its pointless to deep dive anywhere until I can verify my fuel system hold pressure properly.

digital sol

Member

those plugs don't look bad to me, bad lean would be white irrc. one thing about running and pulling the choke, if you have an air leak in the fuel delivery, and pull the choke, it will die right there (no more fuel to give) if its lean because of the carb setting, it will pick up.

Yes, when you pull the choke it wants to die out/bog hard. I only pulled for a short second and it did not actually kill the ski but it felt like it would have had I held the choke longer. I certainly did not gain any rpm it was an instant loss of power w/choke pulled.

I am going to check the fuel system/pressurization first. Thanks for the information I really appreciate it everyone! I am sure it will turn out to be something really small and stupid known as a gremlin

soccerdad

Well-Known Member

So the rectifier is for controlling the charging. BUT if it goes bad, or is not working, it will send and A/C or high voltage feed to the MPEM and this has been known to kill high RPMs. You have worked so hard on it, that this is a definite one to try. Especially since it is so easy.This is a confusing option to me because I am not using the oem rectifier. I am using an OSD aftermarket unit with a plug n play harness for my ski. I could remove the new rectifier completely and retest but would the rectifier prevent the ski from revving higher? I was under the impression it simply charges the battery as you drive it.

I went with a aftermarket unit because the factory unit was replaced at a shop a while ago and the ski still had charging issues and also constant 12v low on indicator. After switching to the OSD unit & charging the battery the 12v low has not come back on where as before it was constant while driving for the most part.

I do not think the pop-off has anything to do with this. The pop-off controls the transition from low to mid range, so that does not seem to be the issue. I am also skepticle about the fuel supply being the issue since you seem to have shown it is not lean up top. (although I have not read the entire thread word by word). So I am thinking some kind of timing issue, or a bad coil that may not want to build enough voltage that quickly (not sure if this happens on Seadoos...), perhaps corrosion around the coil or terminals, or a restriction in the exhaust that is keeping it from breathing, or a pump that creates a bunch of friction when it turns fast, or a plugged up air box keeping it from breathing, or you are really not getting the throttle plates all the way open, or something else (which it probably is...)

That's correct[MENTION=57920]racerxxx[/MENTION] 97 was the service builtin about the rave valves correct

Rabid

Active Member

I noticed something you said earlier on the thread. Here is what Dr Honda told me last year about my carb rebuild.

http://www.seadooforum.com/showthread.php?79143-carb-pop-off-issue

In a thread of mine Dr Honda told

me not to have 2 different springs in the carb

http://www.seadooforum.com/showthread.php?79143-carb-pop-off-issue

In a thread of mine Dr Honda told

me not to have 2 different springs in the carb

digital sol

Member

Bringing her back. Moved into a new place, garage is setup and i've purchased some more skis with a major build to come but for now back to this GTX.

Tore her down, check rotary valve timing "was off a tooth".

Carbs had a pinch in the fuel diaphram.

Rave valve cap was cracked on one valve. I cut the caps to check their functionality and am re-testing pop off etc today.

Should be able to run her on the hose tomorrow. I am pretty sure I would have noticed the damage rave cap so am thinking it was probably from the shop that worked on it while I was on vacation over-tightening it. Ski was left in Springfield the rest of last summer so this is the first time I have really got back to check anything on it.

I tested the vent valves and all worked as they should. "Was worried about this because the gas tank never "vents" anymore when removing the cap there is no pressure like their used to be before the restoration. I will check out the manual for pressure testing this as well. I have a 96 xp parts ski for a different build I will be starting shortly so going to also snag the pump off of that motor, test it out, replace the lines & go back to oil injection on the gtx.

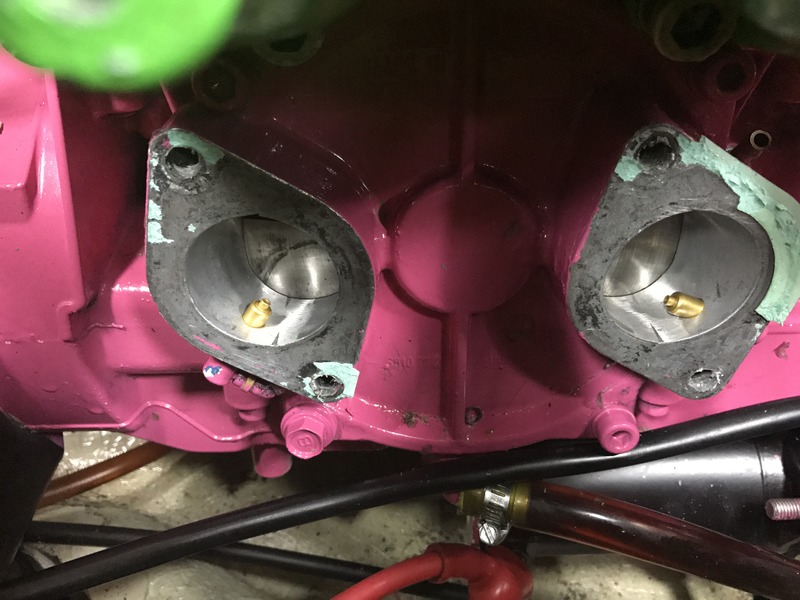

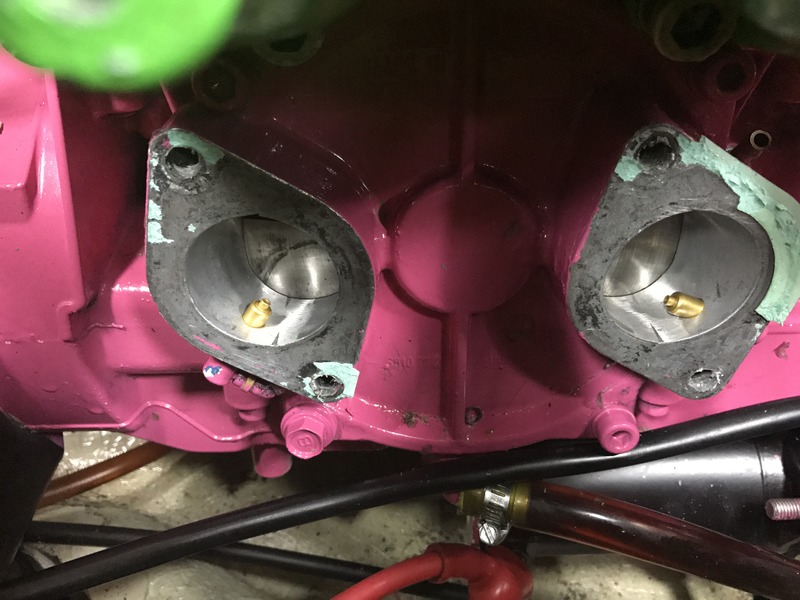

little leak area it would seem

Pinched spot here

Tore her down, check rotary valve timing "was off a tooth".

Carbs had a pinch in the fuel diaphram.

Rave valve cap was cracked on one valve. I cut the caps to check their functionality and am re-testing pop off etc today.

Should be able to run her on the hose tomorrow. I am pretty sure I would have noticed the damage rave cap so am thinking it was probably from the shop that worked on it while I was on vacation over-tightening it. Ski was left in Springfield the rest of last summer so this is the first time I have really got back to check anything on it.

I tested the vent valves and all worked as they should. "Was worried about this because the gas tank never "vents" anymore when removing the cap there is no pressure like their used to be before the restoration. I will check out the manual for pressure testing this as well. I have a 96 xp parts ski for a different build I will be starting shortly so going to also snag the pump off of that motor, test it out, replace the lines & go back to oil injection on the gtx.

little leak area it would seem

Pinched spot here

digital sol

Member

Tested pop off and both popped at 32 and damn near instantly sealed again. Tested fuel diaphram by pump pulse line to 5psi and standing for 10 seconds, no fluctuation.

I'll not that the first time testing the carbs the fuel pump side did bleed air according to the guage but it was not leaking from the seat and after moving some stuff around and retesting no longer had this issue. Could has been from my tester or a line but seemed to fix itself. Even though the guage was lowering after testing pop off it was sealing enough to pop again strongly by tapping the lever with my finger.

I'll not that the first time testing the carbs the fuel pump side did bleed air according to the guage but it was not leaking from the seat and after moving some stuff around and retesting no longer had this issue. Could has been from my tester or a line but seemed to fix itself. Even though the guage was lowering after testing pop off it was sealing enough to pop again strongly by tapping the lever with my finger.

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 240

Share: