Mariciv

New Member

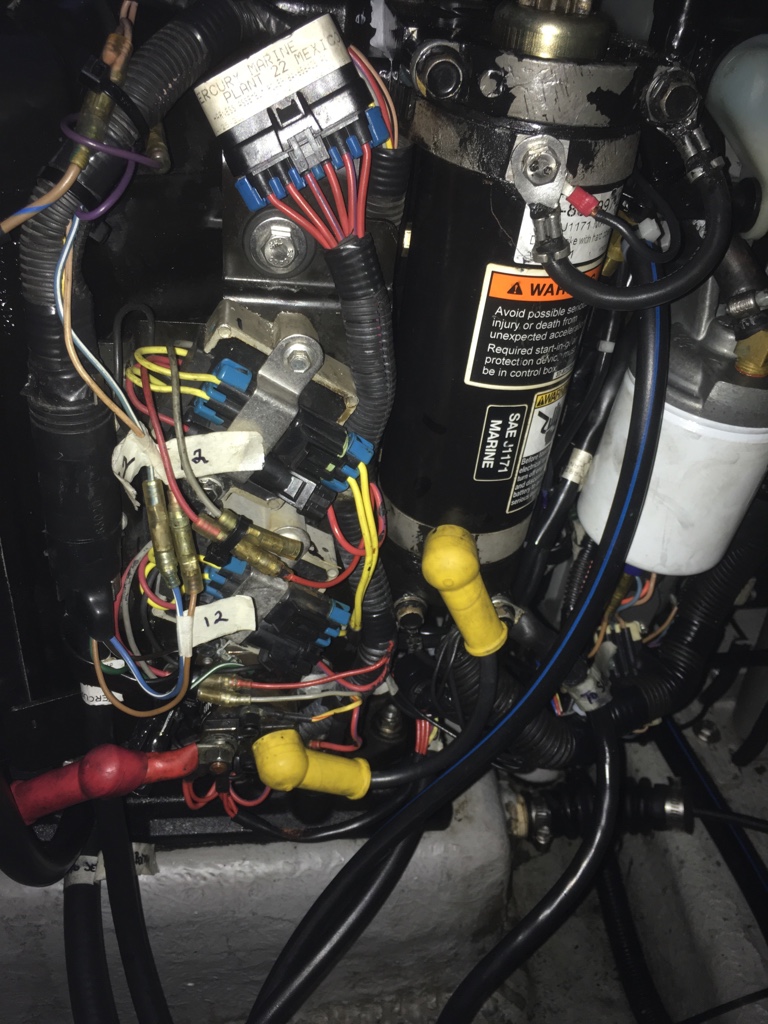

Just received my freshly re sleeves and bored block back and noticed that they planned the top of block but did not fill in the little chip and dent on top of cylinder. See pics. I'm no expert but isn't that exactly where the o-ring sits? If not fixed, water will get in? This place specializes in these engines so I'm surprised that it came back this way.