Mariciv

New Member

Hello,

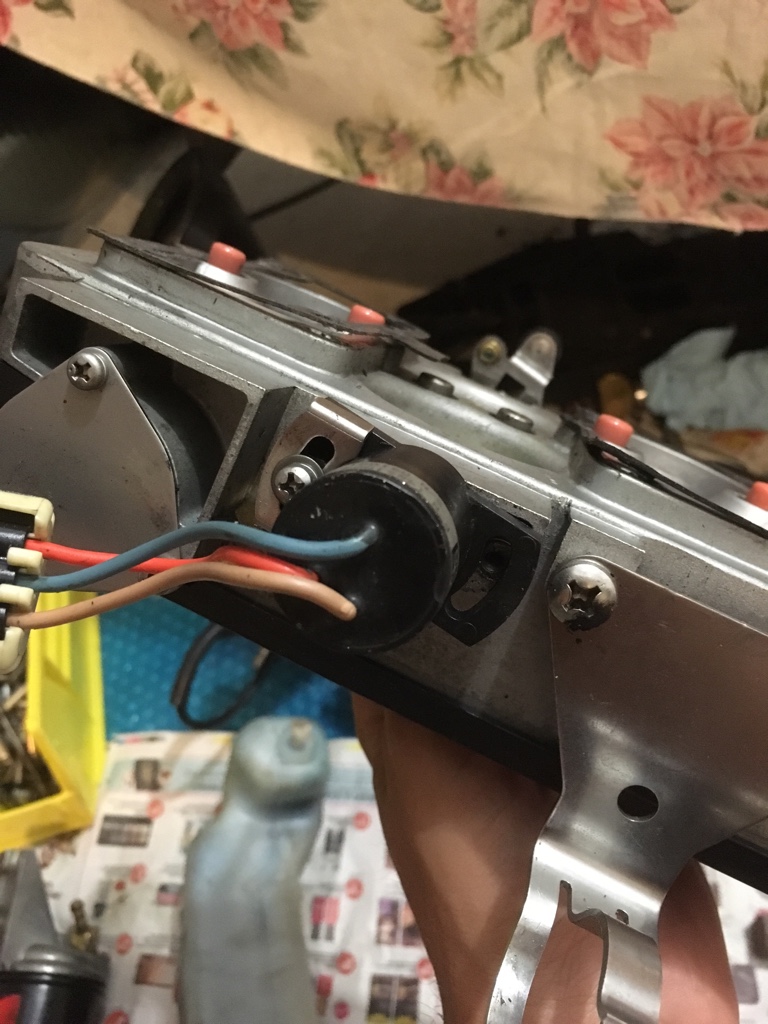

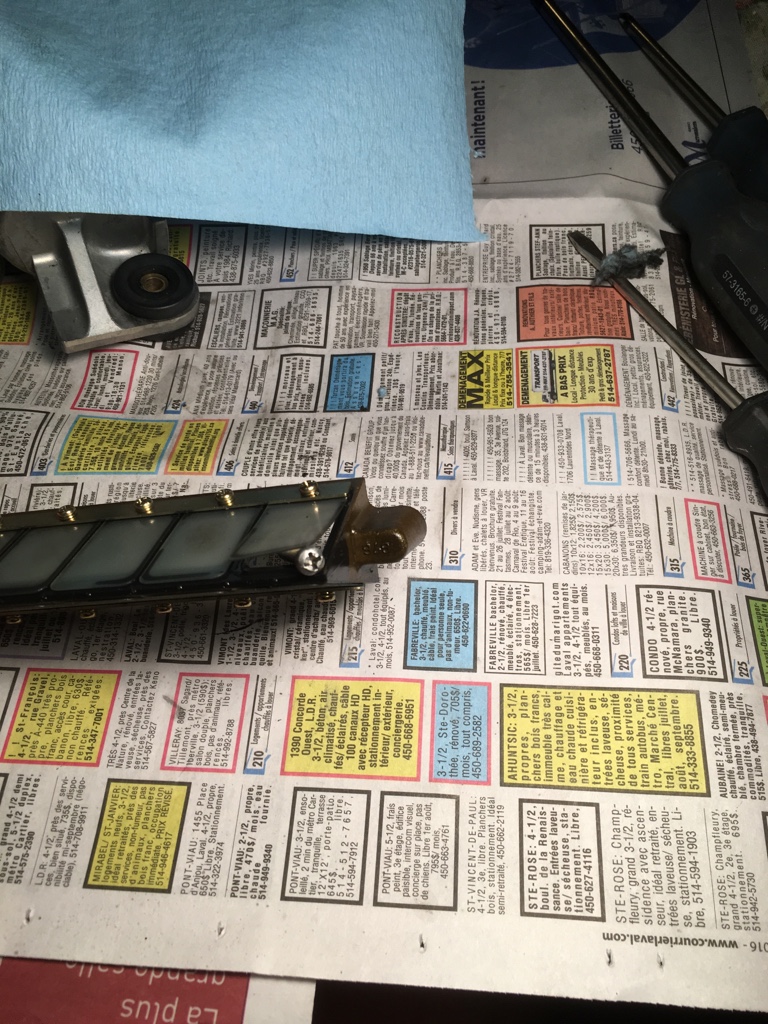

I am new to this forum and this will be my first 240efi rebuild. I bought the 2001 speedster with a busted cylinder (from a dishonest seller) and am now in the process of researching the rebuild. I found a place who will repair and re-sleeve #6 cyl and hone the others. Should I change all the pistons or keep the other 5 original ones? I ordered a full gasket kit, crank bearing kit, rod bolts and head bolts. Do I need to change the crank seal rings? They look ok to me but then again I am no expert. What should I use to replace the bleed hoses? I am sure I will have many more questions during this process so your help will be much appreciated. I will also need a step by step rebuild manual that I can follow during re-assembly. I am pretty handy but not much experience with these engines. I will post some pics of the faulty cylinder which is completely destroyed. The piston is missing about a third of itself.

Thank you

Ivan

I am new to this forum and this will be my first 240efi rebuild. I bought the 2001 speedster with a busted cylinder (from a dishonest seller) and am now in the process of researching the rebuild. I found a place who will repair and re-sleeve #6 cyl and hone the others. Should I change all the pistons or keep the other 5 original ones? I ordered a full gasket kit, crank bearing kit, rod bolts and head bolts. Do I need to change the crank seal rings? They look ok to me but then again I am no expert. What should I use to replace the bleed hoses? I am sure I will have many more questions during this process so your help will be much appreciated. I will also need a step by step rebuild manual that I can follow during re-assembly. I am pretty handy but not much experience with these engines. I will post some pics of the faulty cylinder which is completely destroyed. The piston is missing about a third of itself.

Thank you

Ivan