I did a top end rebuild on my GTXdi last year and have been meaning to post a few pics. I did the Fullbore.com rebuild kit with the Pro-X pistons. So far so good, with about 10-15 hours on the rebuild......

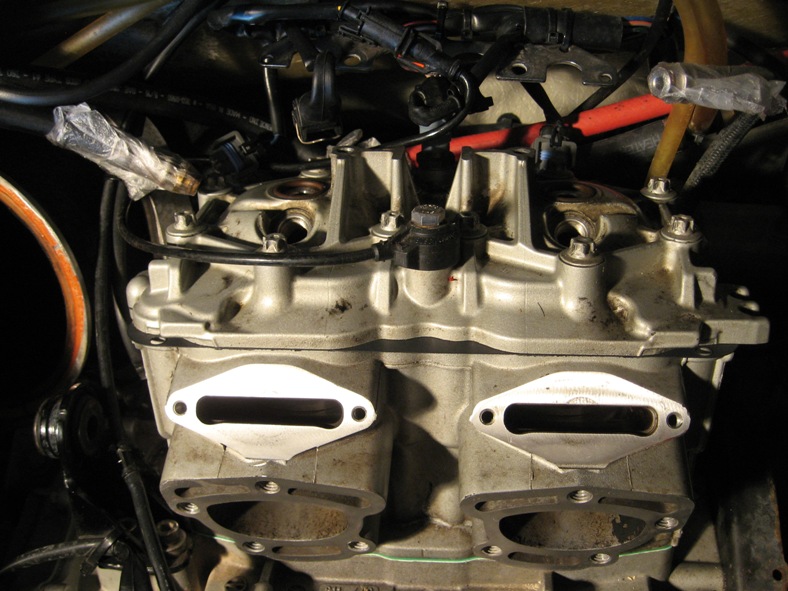

Took the Rave valves out to look into the cylinders. The front piston had basically no compression. This pic I have the fuel injection rail off also.

Starting to tear apart. Took the exhaust off.

By the way, one of these wrenches sure does help when taking off that one bolt/nut on the bottom of the exhaust. I ground some extra metal off the edge to make it fit even better!

Head is off, ready to take the cylinders off.

Took the Rave valves out to look into the cylinders. The front piston had basically no compression. This pic I have the fuel injection rail off also.

Starting to tear apart. Took the exhaust off.

By the way, one of these wrenches sure does help when taking off that one bolt/nut on the bottom of the exhaust. I ground some extra metal off the edge to make it fit even better!

Head is off, ready to take the cylinders off.